Ultrasonic automatic scanning device for large-aperture pipeline in nuclear power plant

A technology for large-diameter pipelines and scanning devices, which is applied in nuclear power generation, measuring devices, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. problems, to achieve the effect of improving rigidity, ensuring inspection accuracy, and facilitating movement and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

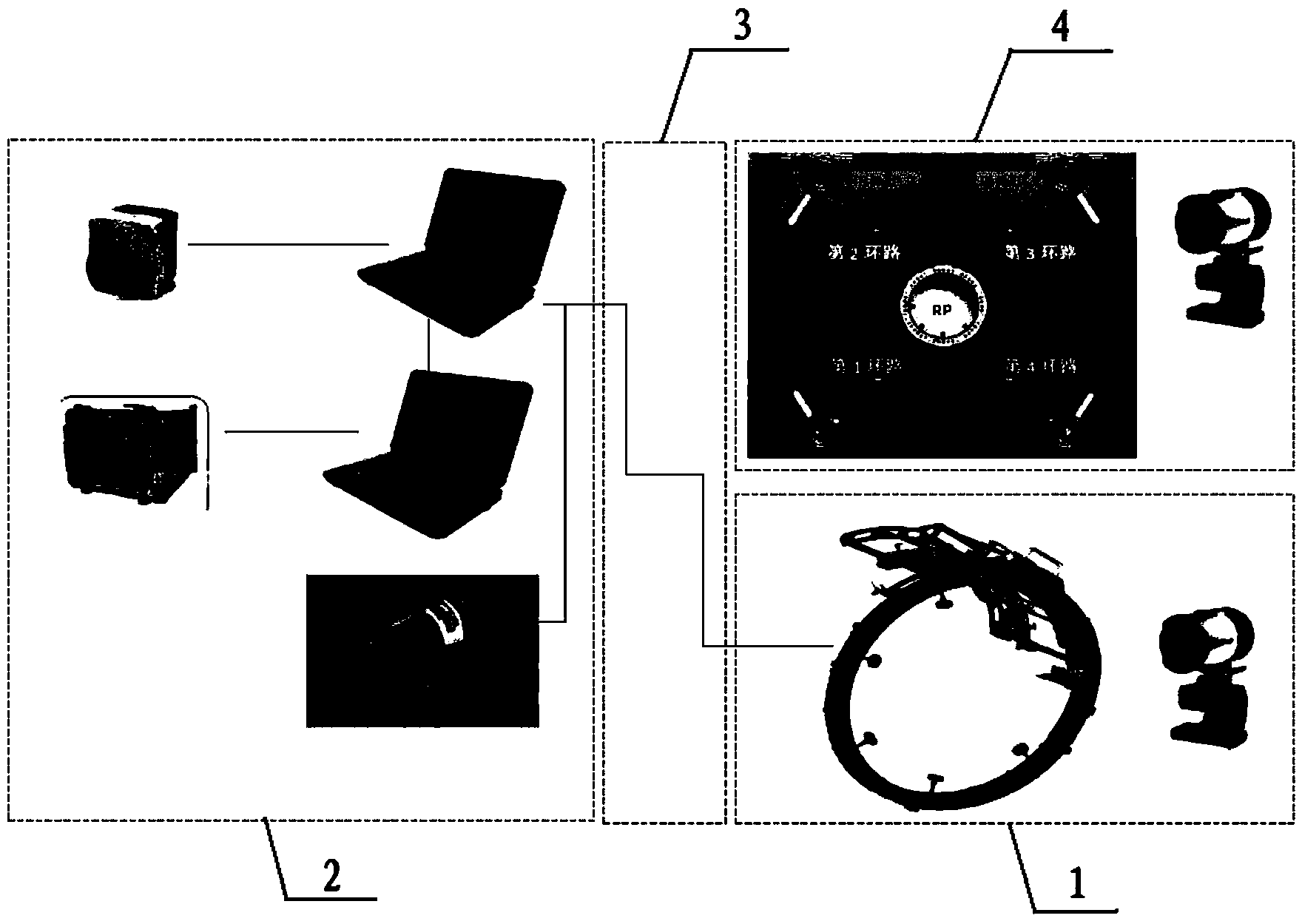

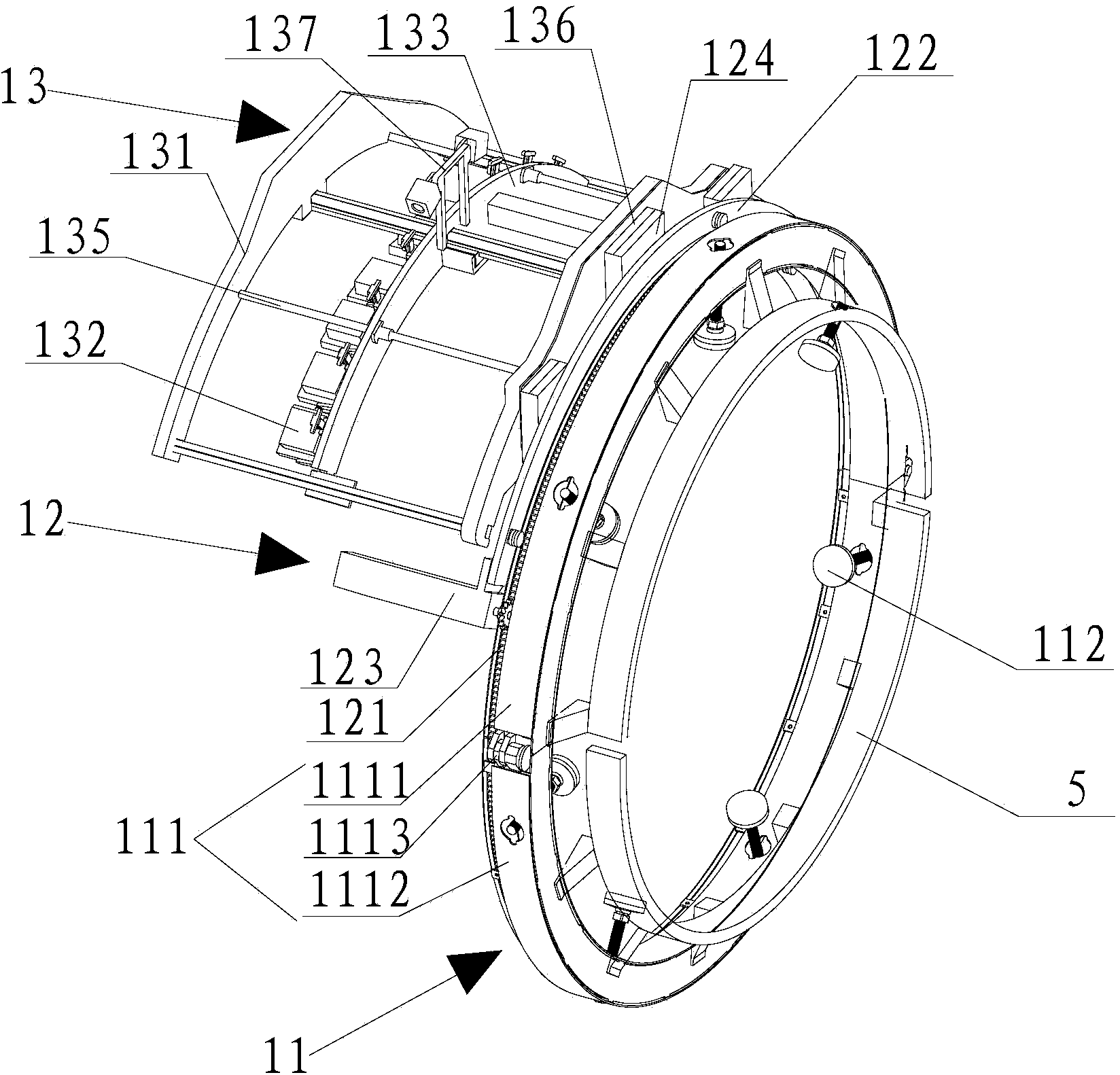

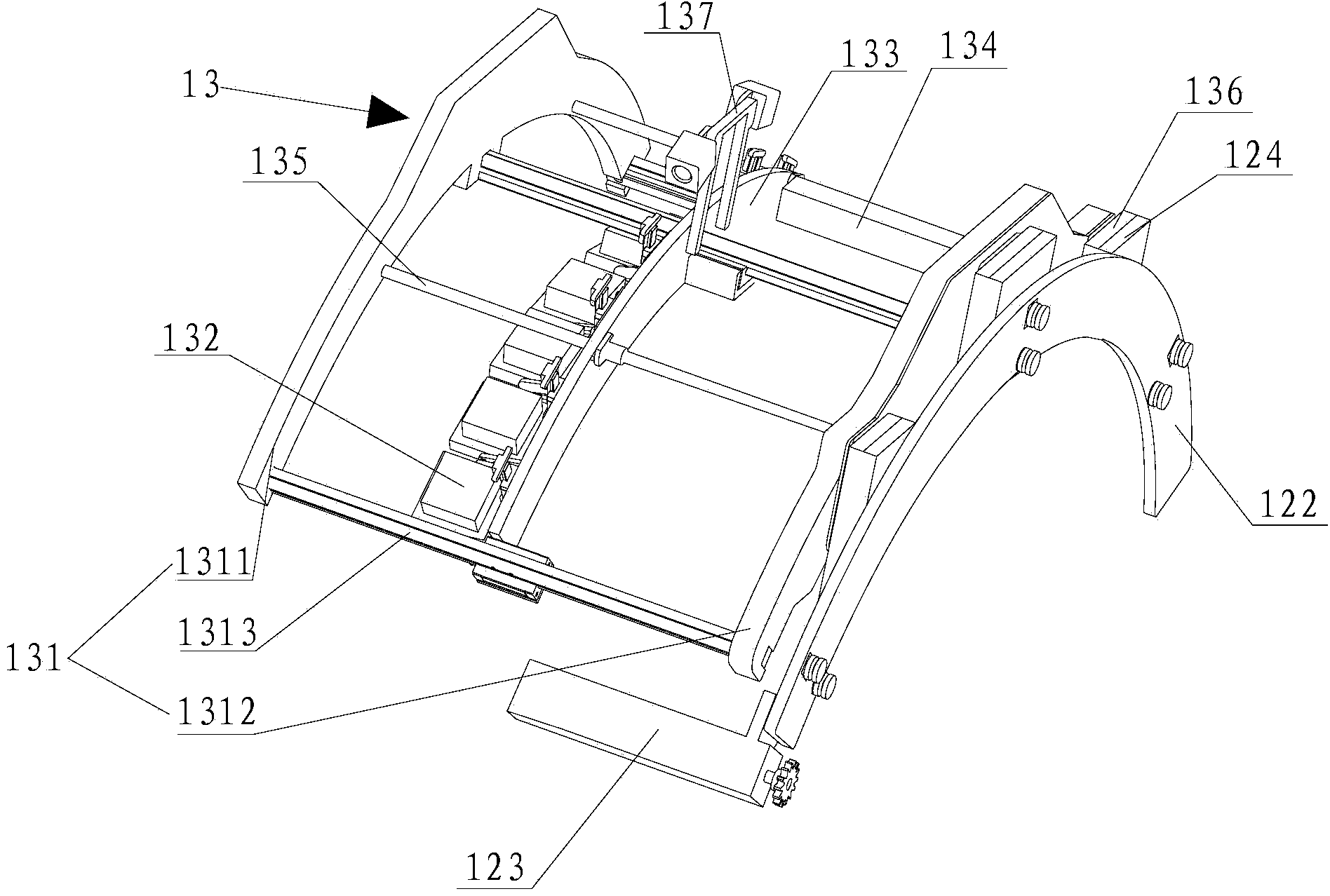

[0026] Such as figure 1 The large-diameter pipeline ultrasonic automatic scanning device of the nuclear power plant shown mainly includes a mechanical scanning part 1, an electric control part 2, and a pipeline part 3, wherein the mechanical scanning part 1 is used to fix on the nuclear power plant pipeline 4 and perform ultrasonic testing on it , see Figure 4 As shown; the electronic control part 2 is used to collect and analyze the signal generated by the mechanical scanning part 1 and intelligently control the mechanical scanning part 1; the pipeline part 3 is used to transmit the signal generated by the mechanical scanning part 1 to the electronic control part 2 1. Feedback the instructions of the electronic control part 2 to the mechanical scanning part 1 and supply the coupling agent to the mechanical scanning part 1 . When in use, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com