A Method for Monitoring the Stability and Uniformity of an Ion Implanter

An ion implanter and ion implantation technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as interference with normal operation of ion implanters, misjudgment of ion implanter status, and high price, and achieve accurate monitoring Effects of stability and uniformity, improved accuracy and stability, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

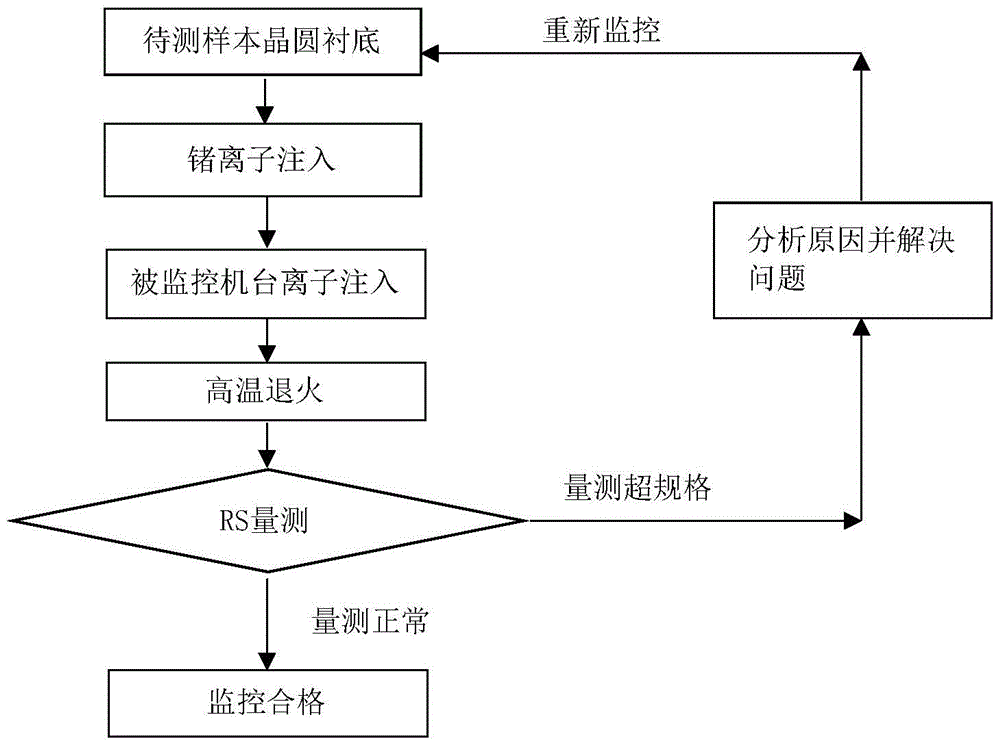

[0035] In this example, see figure 1 , figure 1 It is a schematic flowchart of a method for monitoring the stability and uniformity of an ion implanter in the present invention. As shown in the figure, the method for monitoring the stability and uniformity of an ion implanter in the present invention includes the following process steps:

[0036] First, provide a sample wafer substrate to be tested;

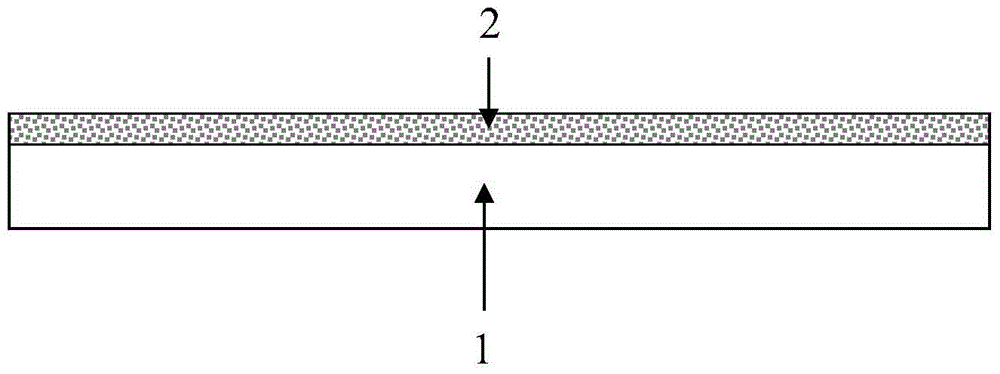

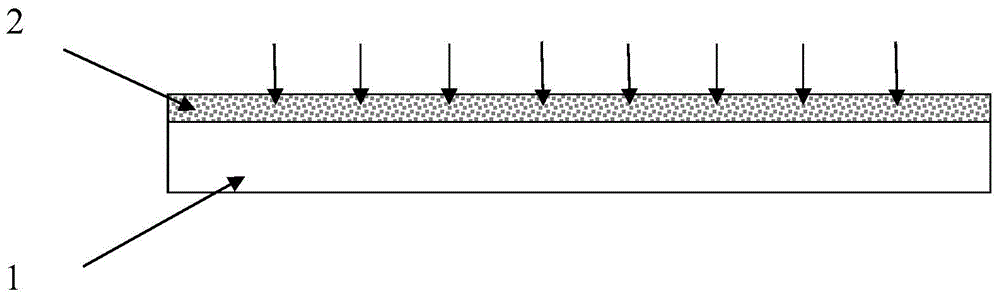

[0037]Secondly, the ion implantation standard machine of the same type as the ion implanter to be monitored is used to ensure high comparability and standard consistency, and the conventional germanium ion implantation process is used to inject germanium ions on the sample wafer substrate to be tested Implanting to form a germanium amorphization barrier layer on the surface of the wafer; the energy of the germanium ion implantation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com