Goat milk soft cheese and preparation method thereof

A production method and cheese technology, which are applied in the field of goat milk soft cheese and its production, can solve the problems of strange shape of cheese, no large-scale production, sour taste, etc., and achieve the effects of uniform shape and size, good palatability and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

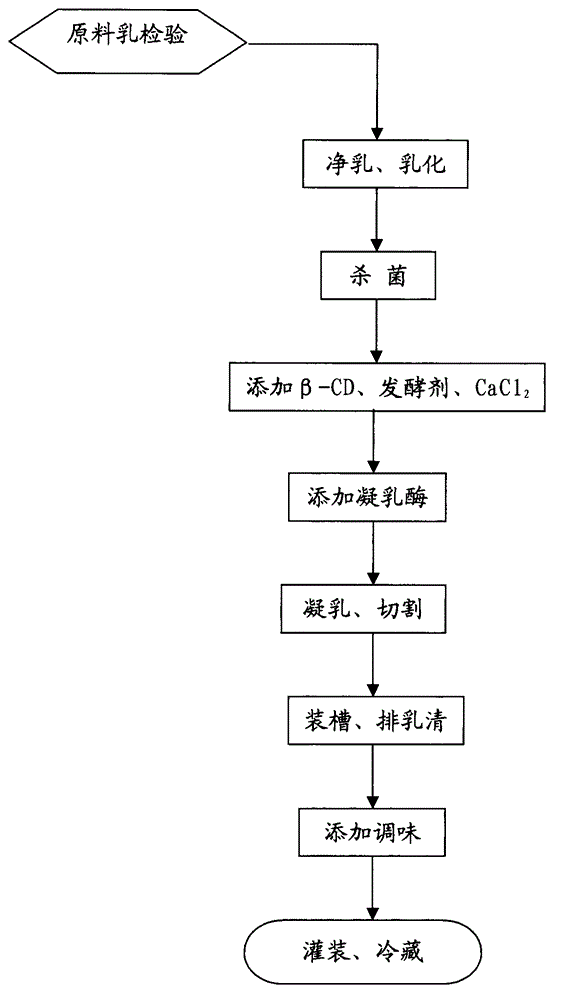

Method used

Image

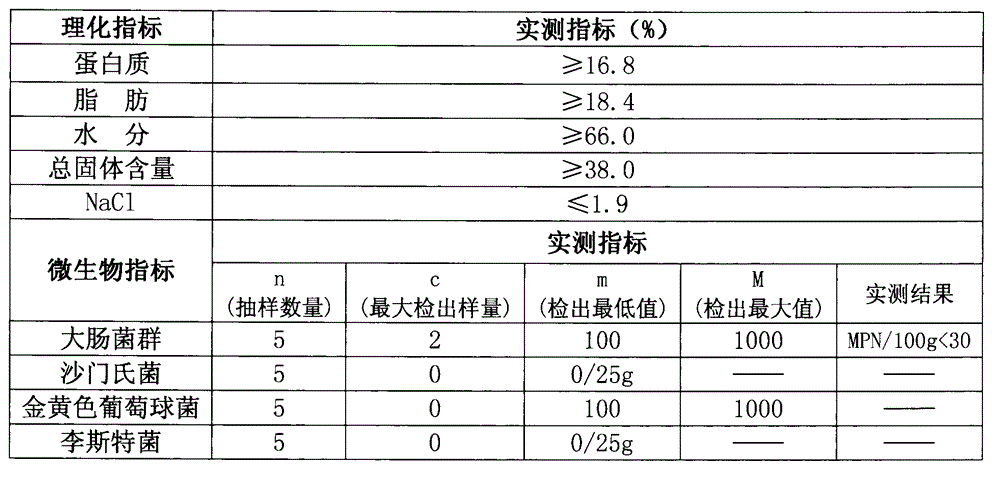

Examples

Embodiment 1

[0021] 1. Acceptance of raw milk

[0022] According to the goat milk acceptance standard, the physical, chemical and microbiological indicators of the purchased fresh goat milk are inspected, and the protein content is required to be ≥3.0%, the fat content is ≥4.0%, the total dry matter content is ≥12%, and the total number of miscellaneous bacteria is ≤1×10 5 Units / mL, acidity ≤16°T, no antibiotics;

[0023] 2. Clean milk and sterilize

[0024] Qualified fresh goat milk is sterilized for 40 seconds at a temperature of 72°C and a pressure of 0.4mPa after plate-and-frame filtration;

[0025] 3. Fermentation and curdling

[0026] After sterilization, lower the temperature of goat milk to 32°C, add 0.1% β-CD by weight of goat milk and stir evenly, then add MA-14 lactic acid bacteria starter with 0.05% weight of goat milk and 0.003% CaCl 2 fully stir;

[0027] Before adding rennet solution, use 1% salt solution to make rennet into 1% rennet solution to activate and maintain th...

Embodiment 2

[0034] 1. Acceptance of raw milk

[0035] Repeat the raw material milk acceptance operation method of embodiment 1;

[0036] 2. Clean milk and sterilize

[0037] Qualified fresh goat milk is sterilized for 30 seconds at a temperature of 75°C and a pressure of 0.5mPa after plate-and-frame filtration;

[0038] 3. Fermentation and curdling

[0039] After sterilization, the temperature of the goat milk drops to 33°C, add 0.1% β-CD by weight of goat milk and stir evenly, then add MA-14 lactic acid bacteria starter with 0.06% weight of goat milk and 0.004% CaCl 2 fully stir;

[0040] Before adding rennet solution, use 1% salt solution to make rennet into 1% rennet solution to activate and maintain the best activity, add 0.8% rennet solution of goat milk weight after 50min After stirring thoroughly, let the curd stand;

[0041] 4. Drain the whey

[0042] After 45 minutes of curdling, when the acidity of the whey reaches 11-12oT and the cut of the curd is smooth, cut it with a s...

Embodiment 3

[0047] 1. Acceptance of raw milk

[0048] Repeat the raw material milk acceptance operation method of embodiment 1;

[0049] 2. Clean milk and sterilize

[0050] Qualified fresh goat milk is sterilized for 30 seconds at a temperature of 72°C and a pressure of 0.6mPa after plate-and-frame filtration;

[0051] 3. Fermentation and curdling

[0052] After sterilization, the temperature of the goat milk drops to 34°C, add 0.1% β-CD by weight of goat milk and stir evenly, then add MA-14 lactic acid bacteria starter with 0.07% weight of goat milk and 0.005% CaCl 2 fully stir;

[0053] Before adding the rennet solution, use 1% salt solution to make rennet into 1% rennet solution to activate and maintain the best activity, and add 1.5% goat milk rennet solution after 60 minutes After stirring thoroughly, let the curd stand;

[0054] 4. Drain the whey

[0055] After curdling for 45 minutes, when the acidity of the whey reaches 11-12oT and the cut of the curd is smooth, cut it with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com