Sesame Milling Process and Its Special Milling System

A sesame and process technology, which is applied in the field of sesame milling process and its special milling system, can solve the problems of unsuitable industrial-scale application, low cleaning and cleanliness, complicated structure, etc., and achieves convenient large-scale industrial production and smooth process. , the effect of reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

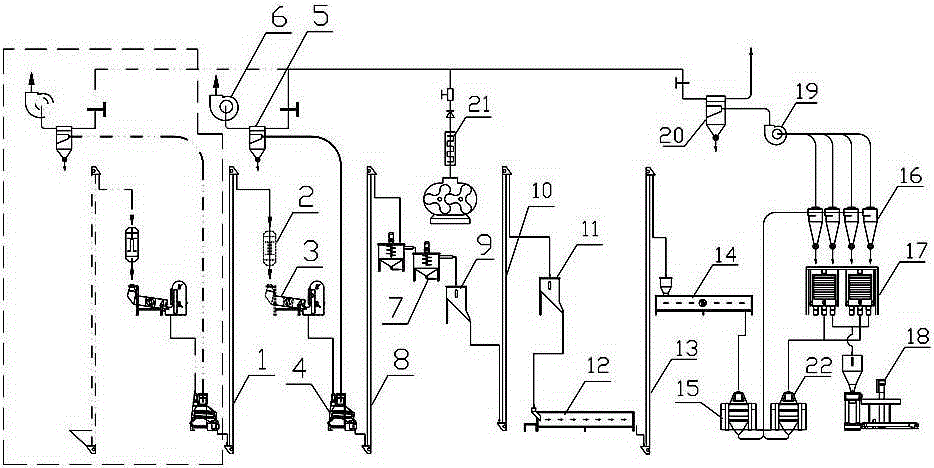

[0012] The sesame flour milling process of the present invention includes the steps of cleaning, drying, cooling, milling, and screening: the cleaning step includes: firstly, the sesame is passed through a magnetic separator to remove iron-containing impurities, and then sent to a vibrating screen for screening , the screened sesame is sent to a cyclone washing machine for water washing after being destoned by a grading destoner; the drying and cooling steps include: sending the washed sesame to a rotary dryer for drying after filtering water, The drying temperature is adjusted between 65-120°C according to the temperature and humidity of the washed sesame seeds, and the drying time is controlled between 2-6 minutes; then it is sent to a rotary cooler for cooling, and the cooling temperature is -10-20°C. The cooling time is 1-4 minutes; the grinding and sieving steps include: sending the cooled sesame into a toothed roller mill for crushing, and sending the crushed sesame into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com