Novel process for BC urban sewage treatment

A technology of urban sewage and new technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effect of simple process, saving operating costs, and convenient operation of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

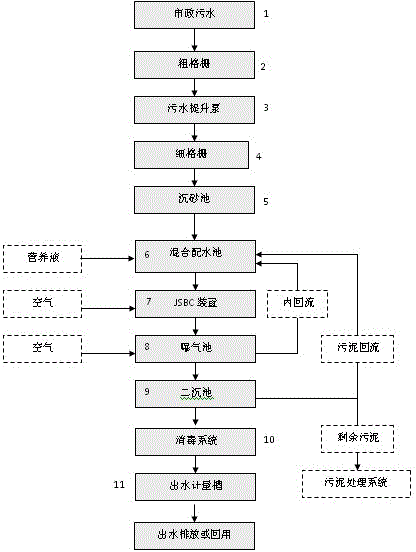

[0028] Embodiment 1: A new process for BC urban sewage treatment, which consists of the following steps, the first step: domestic sewage enters the coarse grid well through the municipal pipe network to remove large volumes of pollutants, and the coarse grid mesh is 25 mm; Step 2: The water from the coarse grid well flows into the sewage lift pump well, and then from the sewage lift pump well to the fine grid well through the lift pump. The fine grid will intercept impurities and large particles in the water, and the fine grid mesh is 1.5 mm; the third step: the water from the fine grid well flows into the grit chamber, and the sediment in the water is settled in the grit chamber; the fourth step: the water from the grit chamber flows into the mixing distribution tank, and in the mixing distribution tank, the secondary sedimentation tank returns sewage The mud, the return sewage of the aeration tank and the raw water are mixed, and the mixing ratio is 1:1:2; the fifth step: the...

Embodiment 2

[0029] Embodiment 2: A new process for BC urban sewage treatment, which is composed of the following steps, the first step: the domestic sewage enters the coarse grid well through the municipal pipe network to remove large volumes of pollutants, and the coarse grid mesh is 65mm; the second Step 2: The water from the coarse grid well flows into the sewage lift pump well, and then from the sewage lift pump well to the fine grid well through the lift pump. The fine grid will intercept impurities and large particles in the water, and the fine grid mesh is 17mm; The third step: the effluent of the fine grid well flows into the grit chamber, and the grit chamber settles the sediment in the water; the fourth step: the effluent of the grit chamber flows into the mixing distribution tank, and in the mixing distribution tank, the secondary sedimentation tank returns sludge, The return sewage and raw water in the aeration tank are mixed, and the mixing ratio is 1:1:2; the fifth step: add ...

Embodiment 3

[0030] Embodiment 3: A new process for BC urban sewage treatment, which is composed of the following steps, the first step: the domestic sewage enters the coarse grid well through the municipal pipe network to remove large volumes of pollutants, and the coarse grid mesh is 100mm; the second Step 2: The water from the coarse grid well flows into the sewage lifting pump well, and then from the sewage lifting pump well to the fine grid well through the lifting pump. The fine grid will intercept impurities and large particles in the water, and the fine grid mesh is 25mm; The third step: the effluent of the fine grid well flows into the grit chamber, and the grit chamber settles the sediment in the water; the fourth step: the effluent of the grit chamber flows into the mixing distribution tank, and in the mixing distribution tank, the secondary sedimentation tank returns sludge, The return sewage and raw water in the aeration tank are mixed, and the mixing ratio is 1:1:2; the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com