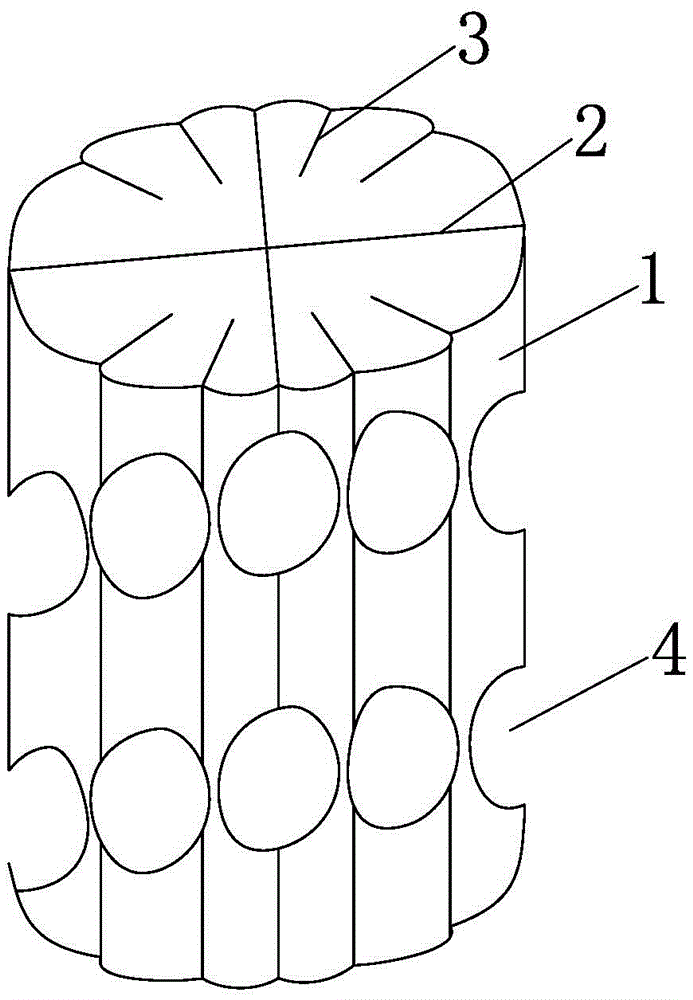

A kind of fluidized bed biofilm filler, preparation method and filler structure

A biofilm and fluidized bed technology, applied in the field of preparation, packing structure, and fluidized bed biofilm packing, can solve the problems of reducing the use efficiency of biological packing, complicated installation of fixed packing, and increasing operating costs, etc., to achieve high efficiency and Long-term expansion of processing scale, improvement of finishing processing effect, and effect of lifting processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 84kg of high-density polyethylene, 1.5kg of titanate, 5kg of activated carbon, 2kg of antioxidant 1010, 3kg of chitin, and 4.5kg of polyvinyl alcohol; put the above materials into a mixer for stirring and mixing, and mix the mixture Move it into a twin-screw injection molding machine and extrude it through a mold, and carry out temperature-programmed roasting in a muffle furnace, and cool after roasting to make the required filler with a density of 0.98g / cm 3 .

Embodiment 2

[0029] Take 90kg of high-density polypropylene, 1kg of aluminate, 3kg of graphite, 1kg of antioxidant TPP, 2kg of starch, and 3kg of polyacrylate; put the above materials into a mixer for stirring and mixing, and move the mixed mixture into a twin-screw In the injection molding machine, it is extruded through a mold, and is roasted in a muffle furnace with a temperature increase. After roasting, it is cooled to make the required filler, and its density is 0.96g / cm 3 .

Embodiment 3

[0031] Take 80kg of high-density polypropylene, 1kg of aluminate, 1kg of titanate, 5kg of carbon black, 5kg of activated carbon, 3kg of antioxidant 1076, 2kg of chitosan, and 3kg of polyvinyl alcohol; put the above materials into a mixer for Stir and mix, move the mixed mixture into a twin-screw injection molding machine, extrude through a mold, and perform temperature-programmed roasting in a muffle furnace, cool after roasting, and make the required filler with a density of 0.98g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com