Halogen-free low-smoke flame-retardant type hard polyurethane foam material and preparation method thereof

A rigid polyurethane, low-smoke flame retardant technology, applied in the field of rigid polyurethane foam material preparation, can solve the problems of poor compatibility, affecting the stability of polyether composites, easy settling, etc. Good, high oxygen index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples. The ammonium polyphosphate used in the following comparative examples and examples is JLS-APP produced by Hangzhou Jieersi, with a degree of polymerization n>1000; the isocyanate is PM200 from Yantai Wanhua; The value is 430mgKOH / g, the foam stabilizer is silicone oil 8805, foaming agent 141b, catalyst pc-8.

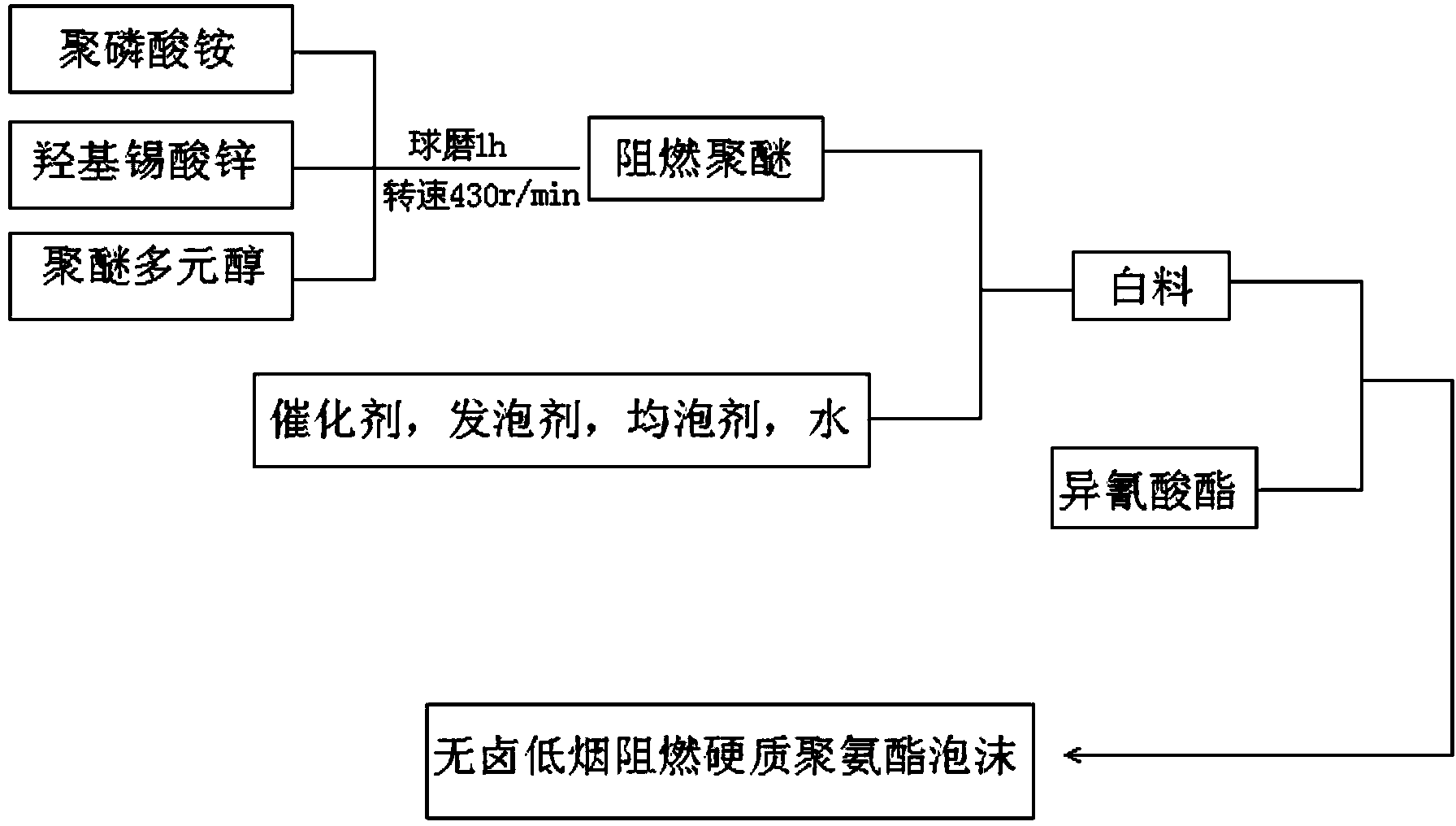

[0026] A preparation method of a halogen-free low-smoke flame-retardant rigid polyurethane foam material, the process flow of its preparation steps is as follows figure 1 Shown, the concrete steps of preparation method are as follows:

[0027] (1) In parts by weight, take polyether polyol, ammonium polyphosphate, zinc hydroxystannate, foaming agent, foam leveling agent, catalyst, water and isocyanate, the formula of comparative examples and embodiments is as shown in table 1 .

[0028] Table 1 Formula of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com