Wax oil treatment device and working method

A processing device and wax oil technology, applied in the direction of refining by filtration, etc., can solve the problems of low processing efficiency, poor operating environment, high labor intensity of cleaning and maintenance, etc., and achieve the effect of optimizing the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

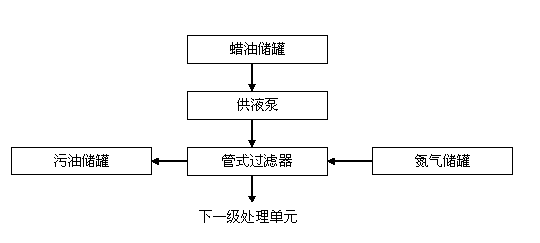

[0015] like figure 1 As shown, the specific embodiment of the present invention mainly includes the following steps: the wax oil enters the filter after being pressurized by the liquid supply pump, the filter is kept at a temperature of 80-90°C to prevent the wax oil from coagulating, and the wax oil passes through the filter element from outside to inside Filtration, insoluble asphaltenes and colloids are separated by the filter element, and the clean wax oil goes to the next-stage processing unit. The asphaltene and colloid on the surface of the filter element are pressurized with nitrogen, and the residual wax oil is followed by blasting and backblowing to decake. Drain the filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com