Intelligent self-circulation well washing device

An intelligent, well-flushing technology that is used in wellbore flushing, wellbore/well components, earth-moving drilling, etc., and can solve problems such as affecting equipment life, inability to handle polymer pollutants, and return of well fluids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

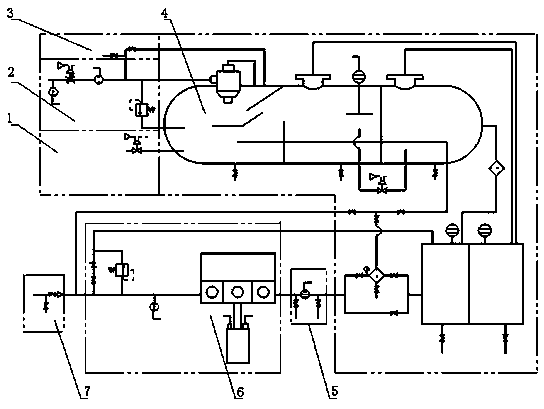

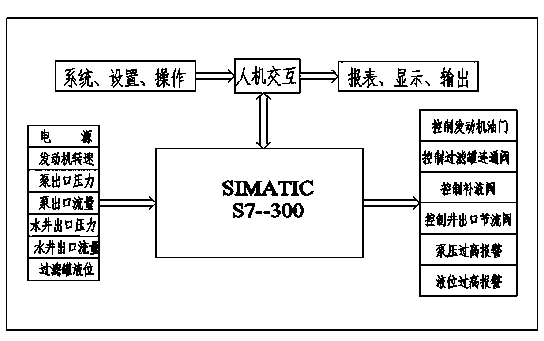

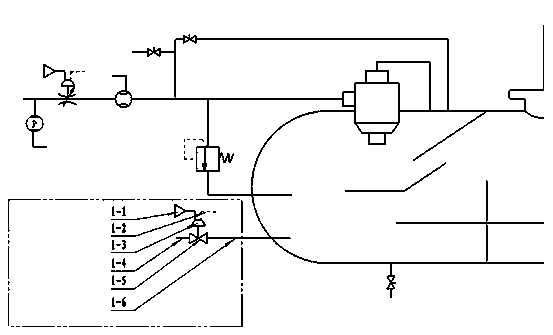

[0039] The intelligent self-circulating water well flushing equipment of the present invention comprises two parts: a flushing liquid circulation processing part and a well flushing process intelligent control processing part. Among them, the circulation processing part of well flushing fluid mainly includes intelligent water well flushing equipment and well flushing process facilities; the intelligent control processing part of well flushing process mainly includes controllers, sensors, actuators and software systems controlled by PLC programming. The two parts cooperate with each other to complete the self-circulating water well flushing process.

[0040] Such as figure 1 as shown, figure 1 It is a structural diagram of a specific embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com