ERG mixer of dual-gas pickup structure

A technology of mixer and mixer core, which is applied in the direction of exhaust gas recirculation, machine/engine, and adding non-fuel substances to fuel, etc. It can solve the problems that the EGR rate cannot be increased, and achieve the reduction of parts, reduction of NOX emissions, and overall The effect of simple machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

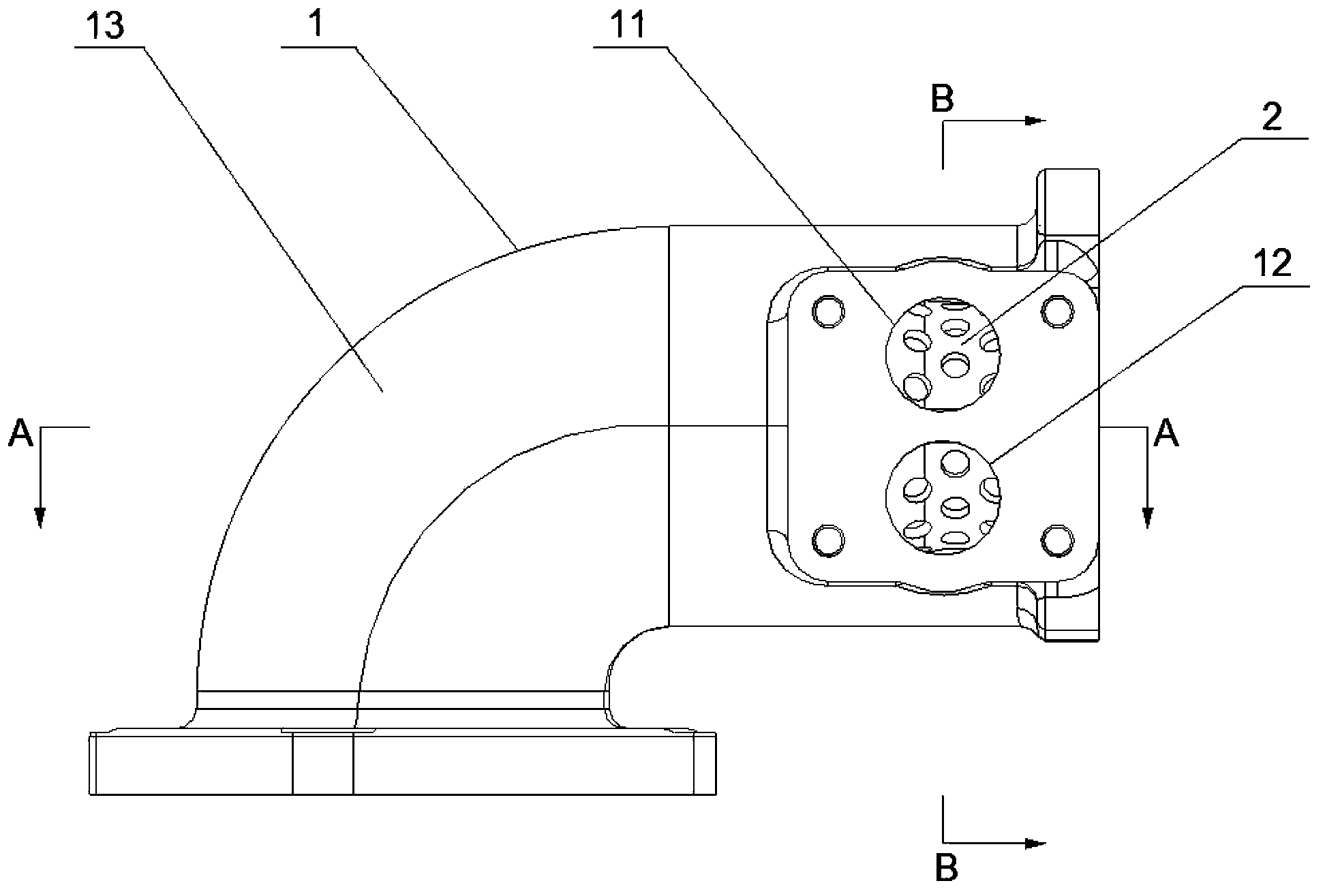

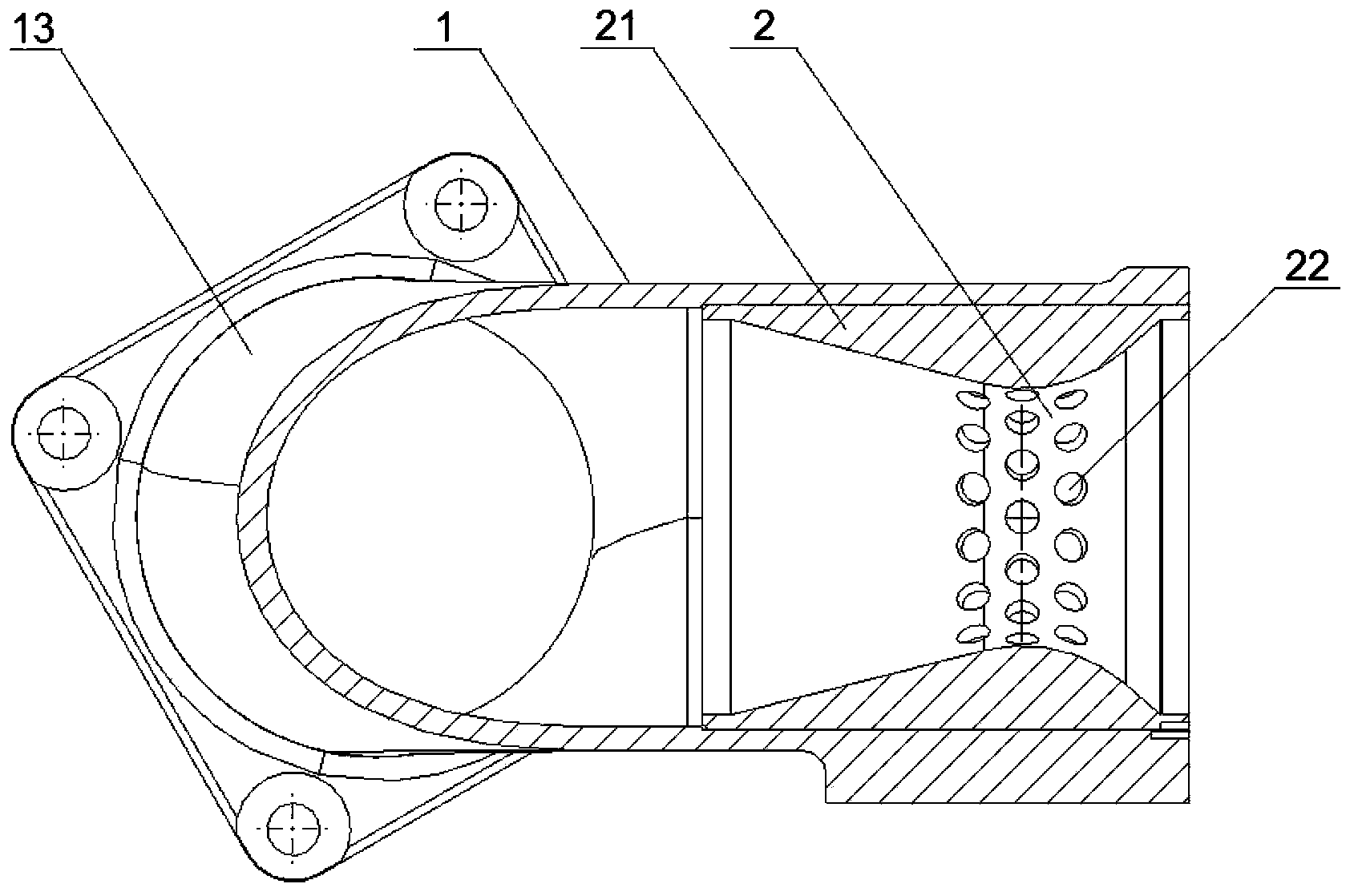

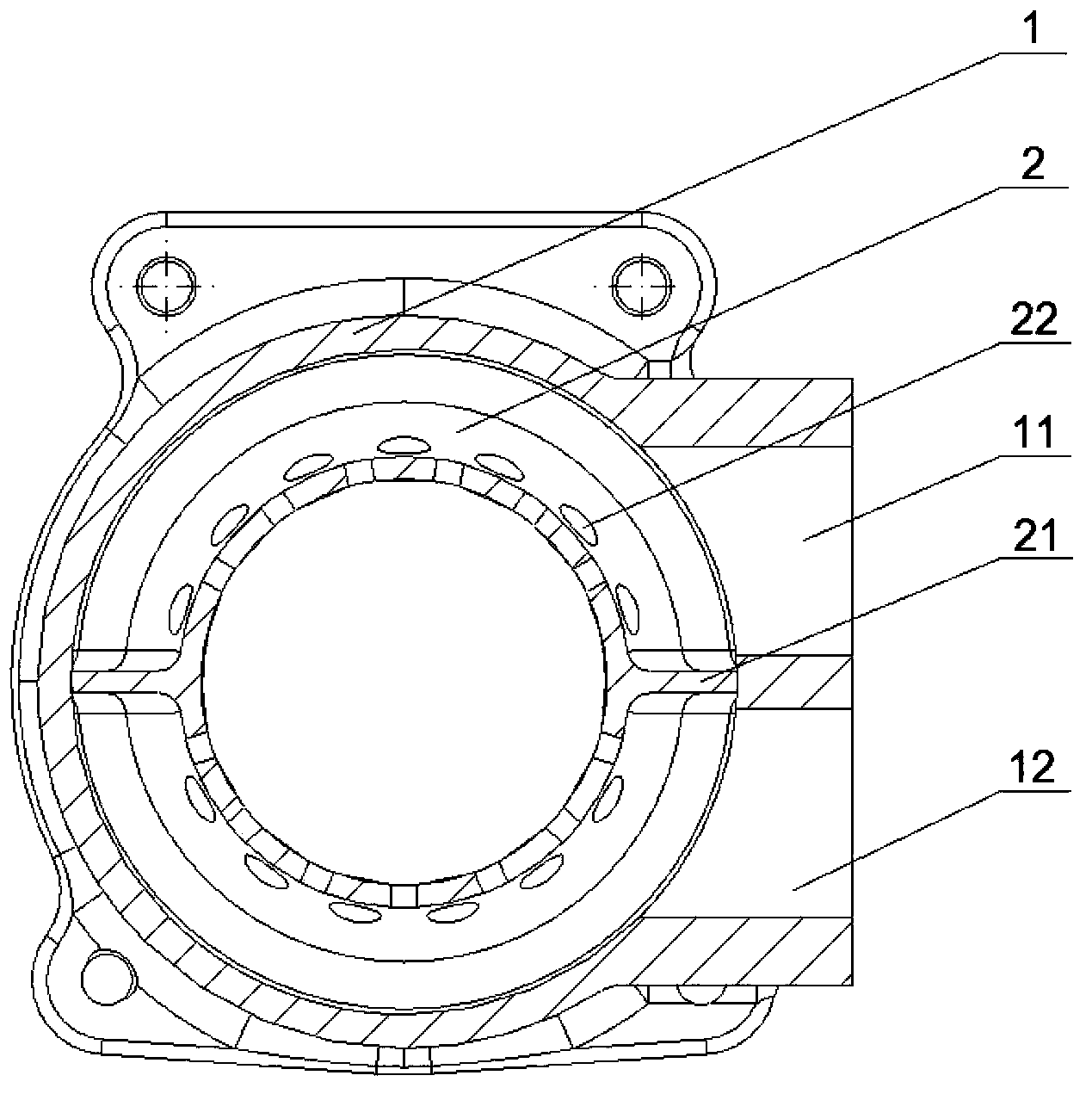

[0027] Such as Figure 1-3 As shown, the EGR mixer with double air intake structure of the present invention is composed of a mixer shell 1 and a Venturi mixer core 2 . The side wall of the mixer housing 1 is provided with a first exhaust gas inlet 11 and a second exhaust gas inlet 12 , and the mixer housing 1 is also integrated with an intake pipe, that is, an air intake pipe section 13 . The partition 21 divides the cavity between the mixer shell 1 and the mixer core 2 into two separate chambers, which are respectively connected to the first exhaust gas inlet 11 and the second exhaust gas inlet 12 . The mixer shell 1 and the mixer core 2 are fixed with positioning pins to prevent relative rotation, so as to keep th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com