An electro-hydrodynamic thruster

A fluid power and thruster technology, which is applied in the aerospace field, can solve the problems of small thrust and low efficiency, and achieve the effect of increasing the thrust-to-weight ratio and improving the propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

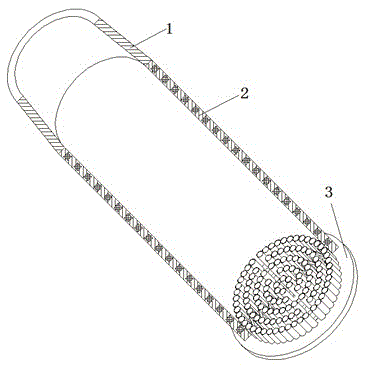

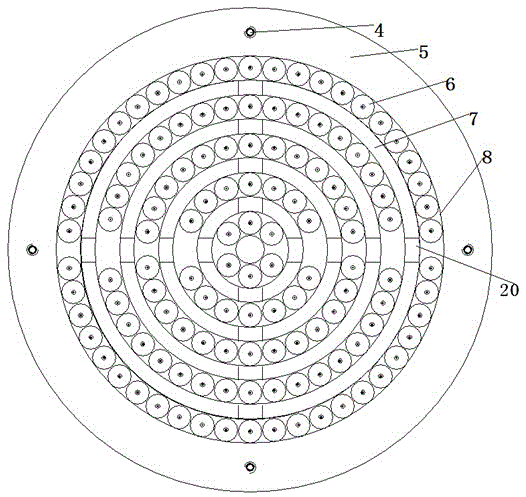

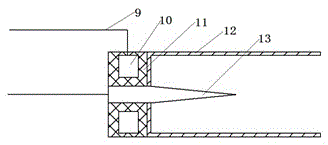

[0029] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 ,

[0030] This embodiment is a propeller that can be used for aerospace vehicles, including a converging nozzle 1, a synchrotron 2, an alternating positive and negative plasma generator 3, a screw hole 4, a support plate 5, an alternating positive and negative Plasma emission unit 6, air channel 7, connection plate 8, wire 9, high-frequency ring electrode 10, insulating material 11, alternating positive and negative plasma emission unit tube body 12, high-frequency high-voltage tip electrode 13, screw assembly Hole 14, synchrotron unit 15, accelerator tube wall 16, grounding 17, wire 18, high-frequency pulse power supply 19.

[0031] see figure 1 , 2 , the alternating positive and negative plasma generator 3 is composed of a screw hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com