Galloping start control method of frequency converter

A frequency converter and flying car technology, applied in the field of inverter flying car start control, can solve the problems of reducing system reliability, relatively large influence of search effect maturity, and complex algorithm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

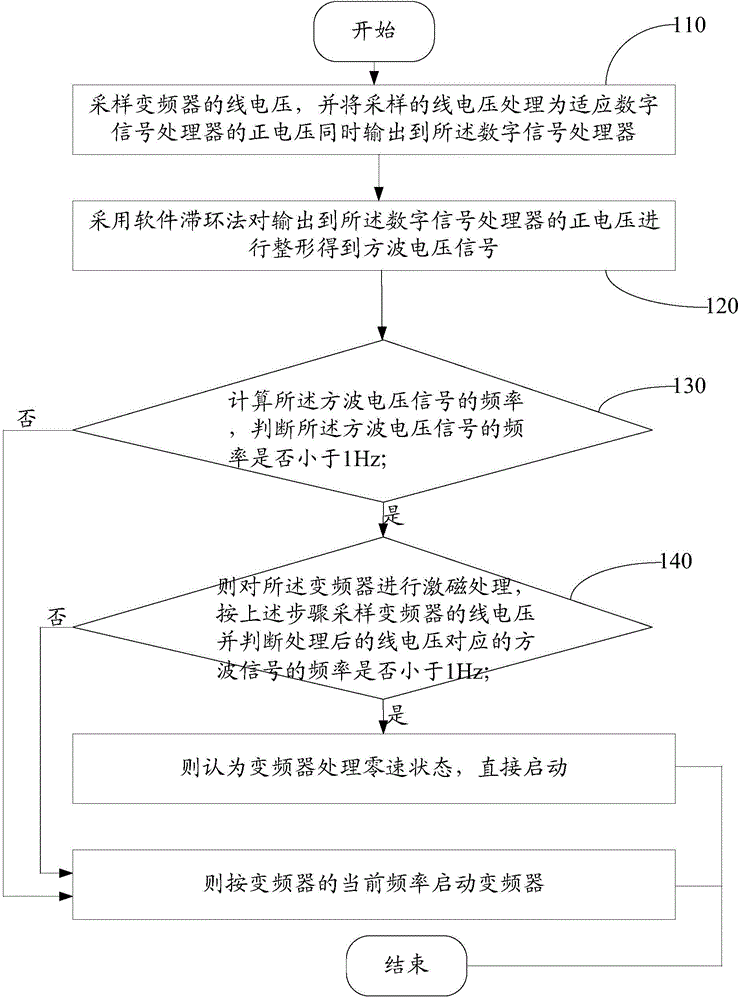

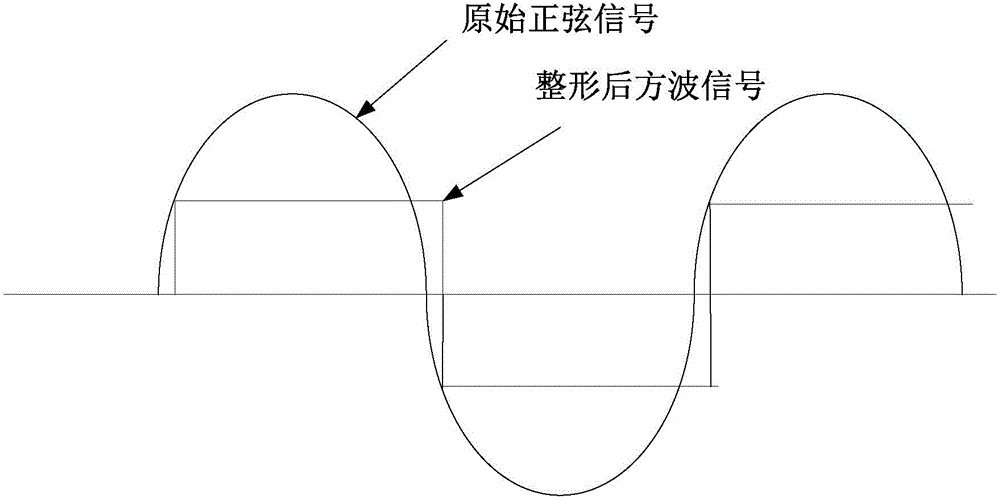

[0052] Such as figure 1 As shown in FIG. 2 , it is a flow chart of the control method for the flying start of the frequency converter.

[0053] A flying start control method of a frequency converter, comprising the following steps:

[0054] Step S110, sampling the line voltage of the frequency converter, processing the sampled line voltage into a positive voltage suitable for the digital signal processor and outputting it to the digital signal processor at the same time.

[0055] The step of sampling the line voltage of the frequency converter includes: sampling two voltages on the line voltage of the frequency converter.

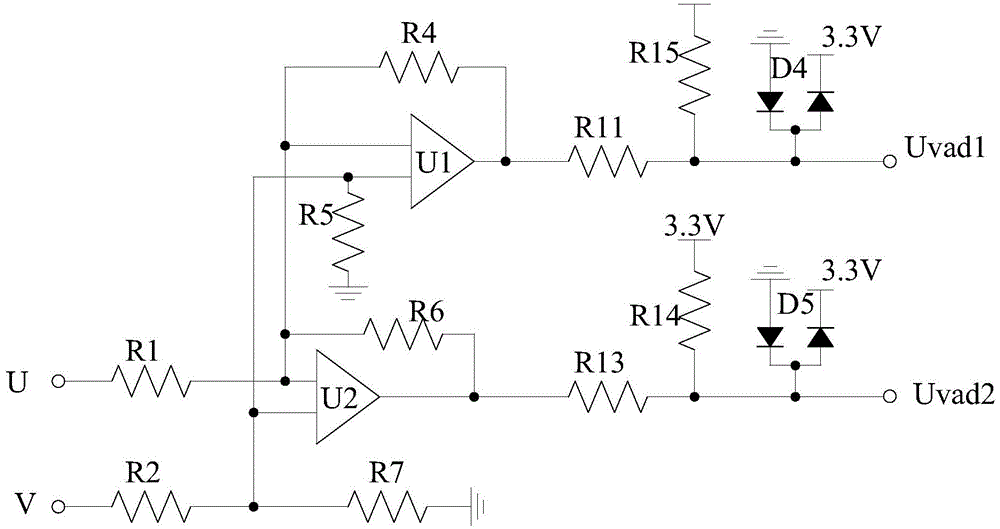

[0056] Specifically, the step of processing the sampled line voltage into a positive voltage suitable for the digital signal processor includes:

[0057] ① The two voltages of the sampled line voltage are amplified by operational amplifiers with two amplification factors.

[0058] ②A pull-up circuit is used to process the amplified line voltage into a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com