A production method of hard-to-deform alloy composite double-layer pipe

A production method and composite double-layer technology, which is applied in the field of alloy seamless pipe production, can solve the problems of poor high-temperature plasticity of difficult-to-deform alloys, the temperature is not in the optimal plastic range, and the difficulty of controlling the thermal processing process, etc., to achieve good thermal processing plasticity , Difficult to delamination cracking, the effect of reducing the tendency of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The material of the hard-to-deform alloy composite pipe is 15Mn / Cr26, the material of the outer layer is 15Mn, and the material of the middle layer is Cr26. The material of the hard-to-deform alloy tube blank is 15Mn / Cr26 / 15Mn, the material of the outer layer is 15Mn, the material of the middle layer is Cr26, and the material of the inner layer is 15Mn (standard: GB / T3077-1999).

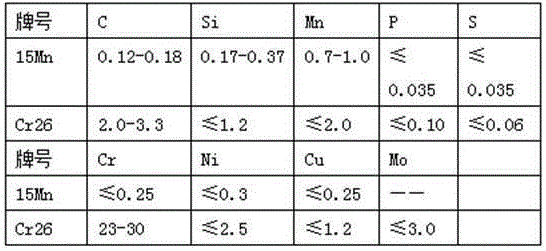

[0028] The chemical composition of the outer layer and the middle layer of the hard-to-deform alloy composite pipe meets the requirements in Table 1, and the specification is φ133mm×14mm / (outer layer 10mm+inner layer 4mm)×5000mm.

[0029] Table 1 15Mn / Cr26 composite pipe composition / mass fraction (%)

[0030]

[0031] The specific production steps are as follows:

[0032] (1) Centrifugal casting hard-to-deform alloy tube billet

[0033] Smelt the outer layer 15Mn and the middle layer Cr26 alloy liquid of the finished tube respectively, first pour the outer layer 15Mn on the centrifugal c...

Embodiment 2

[0051] The material of the hard-to-deform alloy composite pipe is 20Mn / G3, the material of the outer layer is 20Mn, and the material of the middle layer is G3. The material of the hard-to-deform alloy tube blank is 20Mn / G3 / 20Mn, the material of the outer layer is 20Mn, the material of the middle layer is G3, and the material of the inner layer is 20Mn.

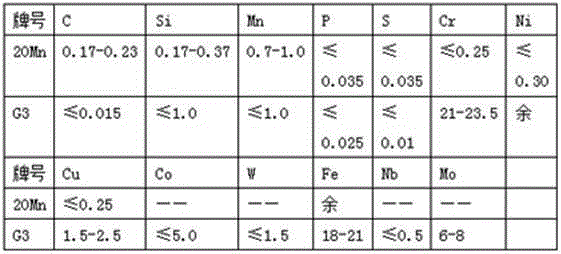

[0052] The chemical composition of the outer layer and inner layer of the hard-to-deform alloy composite pipe meets the requirements in Table 2, and the specification is φ219mm×13mm / (outer layer 9mm+inner layer 4mm)×6000mm.

[0053] Table 2 20Mn / G3 composite pipe composition / mass fraction (%)

[0054]

[0055] The specific production steps are as follows:

[0056] (1) Centrifugal casting hard-to-deform alloy tube billet

[0057] The outer layer 20Mn and the middle layer G3 alloy liquid of the finished tube are smelted separately, and the outer layer 20Mn is first poured on the centrifugal casting machine, then the middl...

Embodiment 3

[0075] The material of the hard-to-deform alloy composite pipe is 20Mn2 / 625, the material of the outer layer is 20Mn2, and the material of the middle layer is 625. The material of the difficult-to-deform alloy tube blank is 20Mn2 / 625 / 20Mn2, the material of the outer layer is 20Mn2, the material of the middle layer is 625, and the material of the inner layer is 20Mn2.

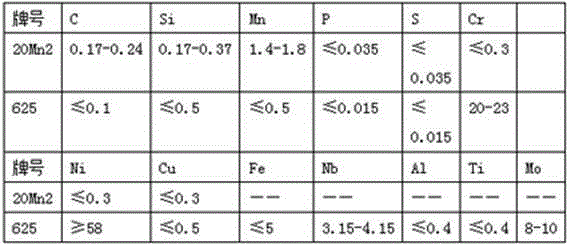

[0076] The chemical composition of the outer layer and inner layer of the hard-to-deform alloy composite pipe meets the requirements of Table 3, and the specification is φ273mm×14mm / (outer layer 11mm+inner layer 3mm)×6000mm.

[0077] table 3 20Mn2 / 625 composite pipe composition / mass fraction (%)

[0078]

[0079] The specific production steps are as follows:

[0080] (1) Centrifugal casting hard-to-deform alloy tube billet

[0081] The outer layer 20Mn2 and the middle layer 625 alloy liquid of the finished pipe are smelted respectively, and the outer layer 20Mn2 is poured first on the centrifugal casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com