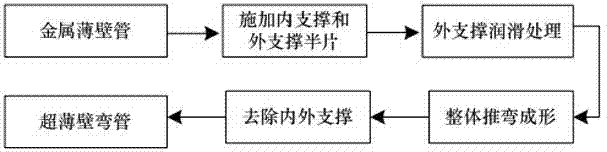

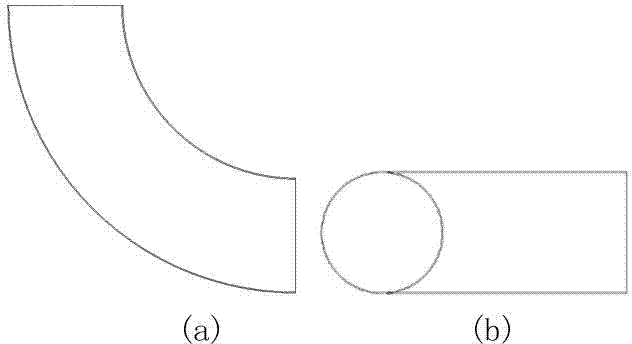

Thin-walled metal tube bending and forming method

A metal tube and thin-wall technology, applied in the field of metal plastic forming, can solve the problems of increasing the friction between the outer wall of the tube and the mold cavity, increasing the complexity of the forming process, and the wrinkling effect is not obvious, so as to eliminate buckling and wrinkling phenomenon, improvement of wall thickness uniformity, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

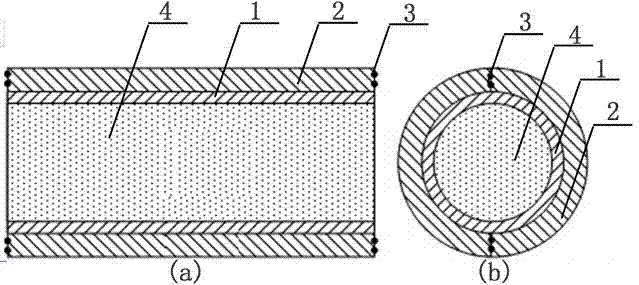

[0025] The first step is to use 1mm thick 6061 aluminum alloy sheet coil welding to form a tube blank 1 with a diameter of 202mm, and the axial length of the blank is about 260mm;

[0026] The second step is to cut the carbon steel pipe 2 with an inner diameter of 202mm, a wall thickness of 3mm, and a plasticity better than 6061 aluminum alloy along the axial direction, and cut it into two symmetrical half pieces, and implement the two half pieces of carbon steel pipe 2. Phosphating and saponification treatment to improve the lubrication conditions of the inner and outer surfaces and reduce friction;

[0027] The third step is to completely cover the 6061 aluminum alloy pipe 1 with the two half pieces of carbon steel, and perform spot welding on both ends of the two half pieces of carbon steel to partially connect the two half pieces of carbon steel;

[0028] The fourth step is to pour a low-melting point alloy inside the 6061 aluminum alloy tube 1, and wait for the low-meltin...

Embodiment 2

[0034] The first step is to blank the titanium alloy seamless pipe 1 with a diameter of 48.5mm and a wall thickness of 1mm, and the axial length of the blank is about 115mm;

[0035] In the second step, the carbon steel pipe 2 with an inner diameter of 48.5 mm, a wall thickness of 2 mm, and a plasticity better than that of titanium alloy is cut in half along the axial direction, and is cut into two symmetrical half pieces, and the two half pieces of the carbon steel pipe are subjected to phosphorus Chemical and saponification treatment, improve the lubrication conditions of internal and external surfaces, and reduce friction;

[0036] In the third step, after the two halves of carbon steel are completely covered with the titanium alloy seamless pipe 1, spot welding is performed on both ends of the two halves of carbon steel to partially connect the two halves of carbon steel;

[0037] The fourth step is to insert cylindrical polyurethane rubber inside the titanium alloy seamle...

Embodiment 3

[0043] The first step is to roll weld the stainless steel with a wall thickness of 1mm to obtain a tube blank 1 with a diameter of 100mm, the axial length of the blank is about 314mm, and seal the tail of the stainless steel tube blank at the same time;

[0044] The second step is to cut the carbon steel pipe 2 with an inner diameter of 100mm, a wall thickness of 5mm, and a plasticity better than stainless steel along the axial direction, and cut it into two symmetrical halves, and then phosphating and curing the two halves of the carbon steel pipe. Saponification treatment to improve the lubrication conditions of the inner and outer surfaces and reduce friction;

[0045] The third step is to completely cover the stainless steel pipe with the two half pieces of carbon steel, and perform spot welding on the end of the carbon steel to partially connect the two half pieces;

[0046] The fourth step is to weld the tail of the carbon steel pipe 2 to seal the bottom, inject filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com