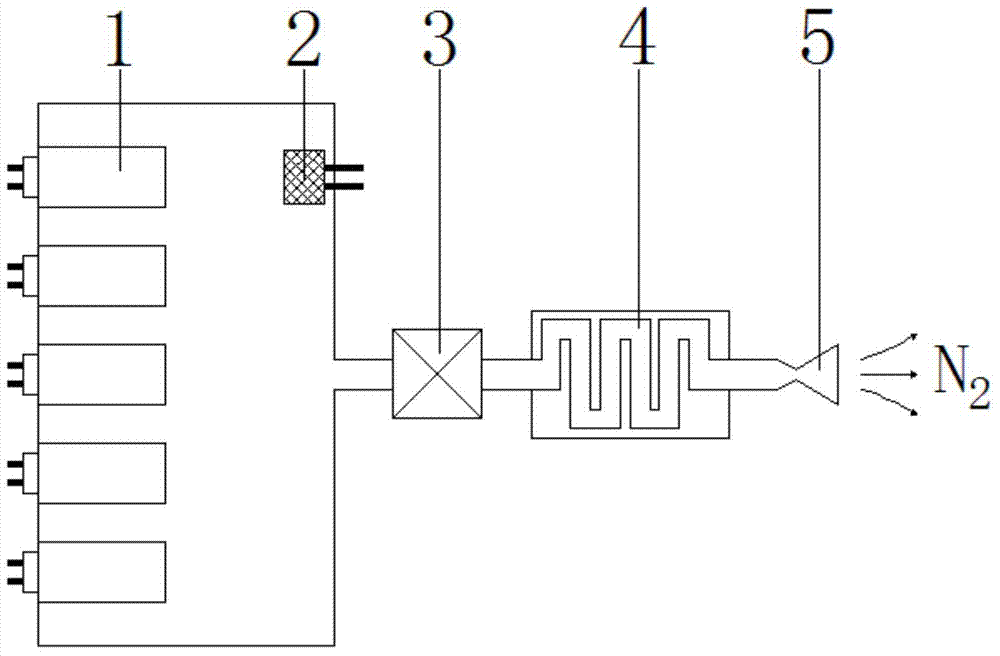

Solid cool air micro-propelling system

A micro-propulsion and air-conditioning technology, which is applied to the propulsion system devices of space navigation vehicles, etc., can solve the problems of inability to apply long-term space missions, gas leakage, and difficulty in applying micro-nano satellites, so as to improve propulsion efficiency, reduce weight, reduce The effect of volume and mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

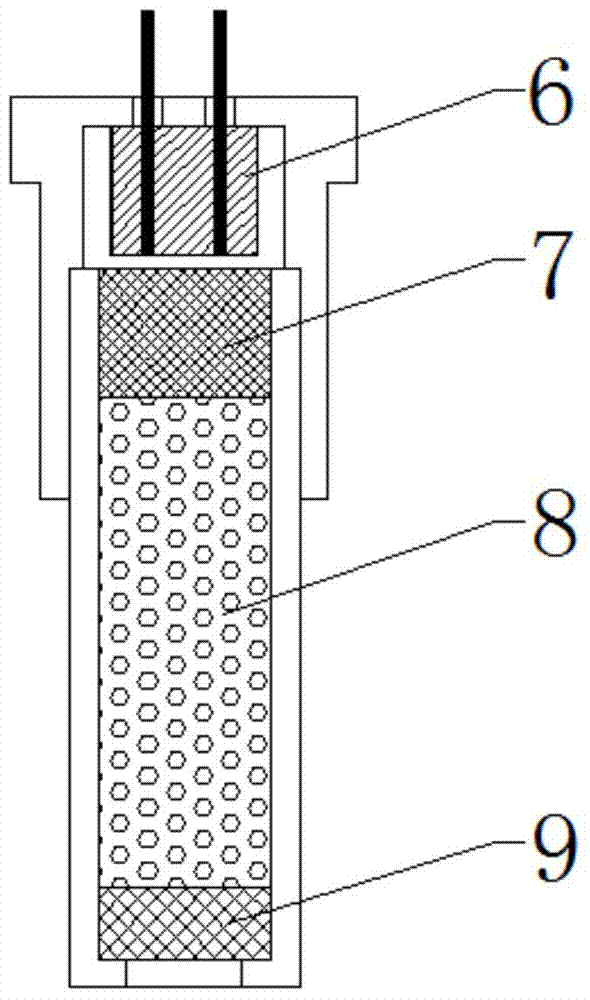

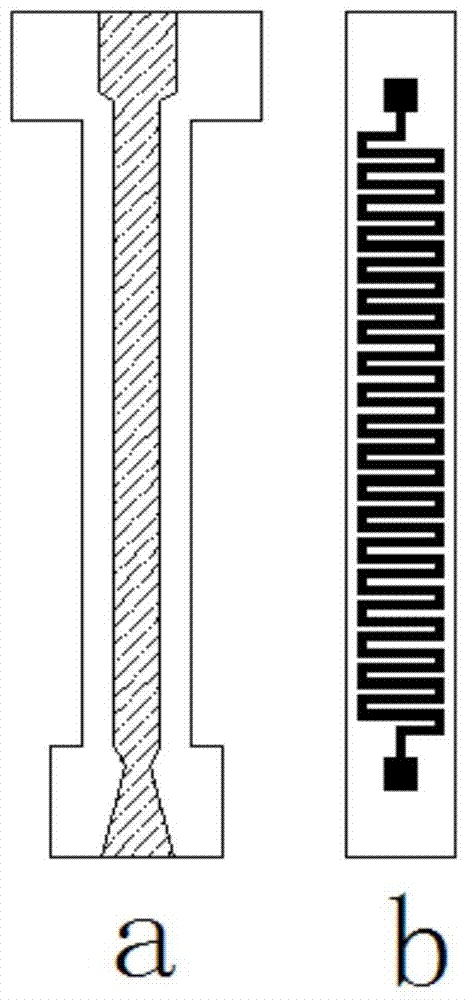

[0044] The overall dimensions of the nitrogen generator 1 are as follows Figure 4 shown. The ignition device 6 in the integrated nitrogen generator 1 selects the ignition head, and the ignition powder used on the ignition head is lead styphate with less gas production, and a layer of shellac paint is added to the outer layer to seal to prevent moisture. There are two layers of powder columns in the medicine chamber, and the uppermost layer is the ignition charge 7. Thermite is used in this embodiment, and the formula is Al / CuO. The next layer is nitrogen generating agent 8, and its formula is as shown in table 2:

[0045] Table 2 Nitrogen generator formula

[0046]

[0047] The weighed NaN 3 , LiF, Fe 2 o 3 (NaCO 3 ), SiO 2 Mix well, NaSiO 3 It is then dissolved in water and heated at a constant temperature of 50°C. Dissolved NaSiO 3 The solution is added to the mixed agent, stirred evenly, and then placed in a constant temperature oven (60°C) for drying. Take i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com