Underwater anti-dispersion mortar for large-area cavity grouting and preparation method thereof

An anti-dispersion, large-area technology, applied in the field of grouting materials and its preparation, can solve the problems of poor anti-dispersion of poured materials, insufficient fluidity of poured materials, and difficulty in receiving ideal effects, etc., to achieve fast raw materials, The effect of reducing the water-binder ratio of mortar and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is described in further detail.

[0015] The present invention adopts polycarboxylate high-performance water reducer and hydroxypropyl methyl cellulose, greatly reduces the water-binder ratio, increases the flocculation and water-resistant dispersibility of the mortar, and makes the grouting mortar have high fluidity and self-flowing The characteristics of compactness, underwater anti-dispersion and high compressive strength can effectively solve the difficulties of the existing technology.

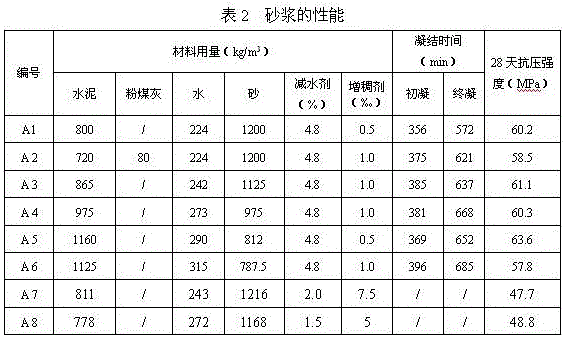

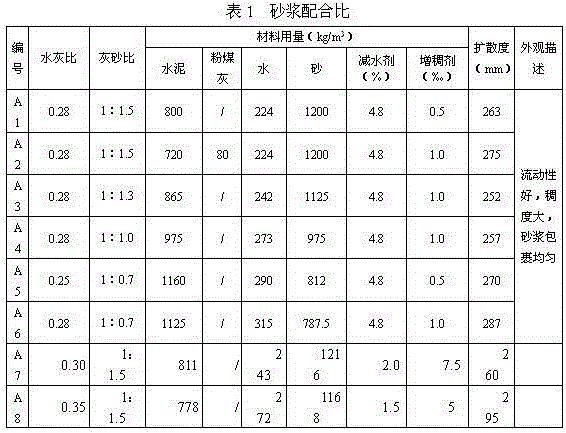

[0016] An example of the present invention is as follows:

[0017] When preparing the present invention, first select cement with a strength of not less than 42.5MPa, national standard II grade fly ash, natural sand or artificial sand with fineness in the range of medium sand, polycarboxylate high-performance water reducer, hydroxypropyl methyl Base cellulose and water are measured separately according to the mixing ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com