Antibacterial polyurethane film and preparation method thereof

A technology of polyurethane film and water-based polyurethane, applied in the field of polyurethane film, can solve problems such as low safety and poor antibacterial properties, and achieve the effects of content optimization, good waterproofness and breathability, and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

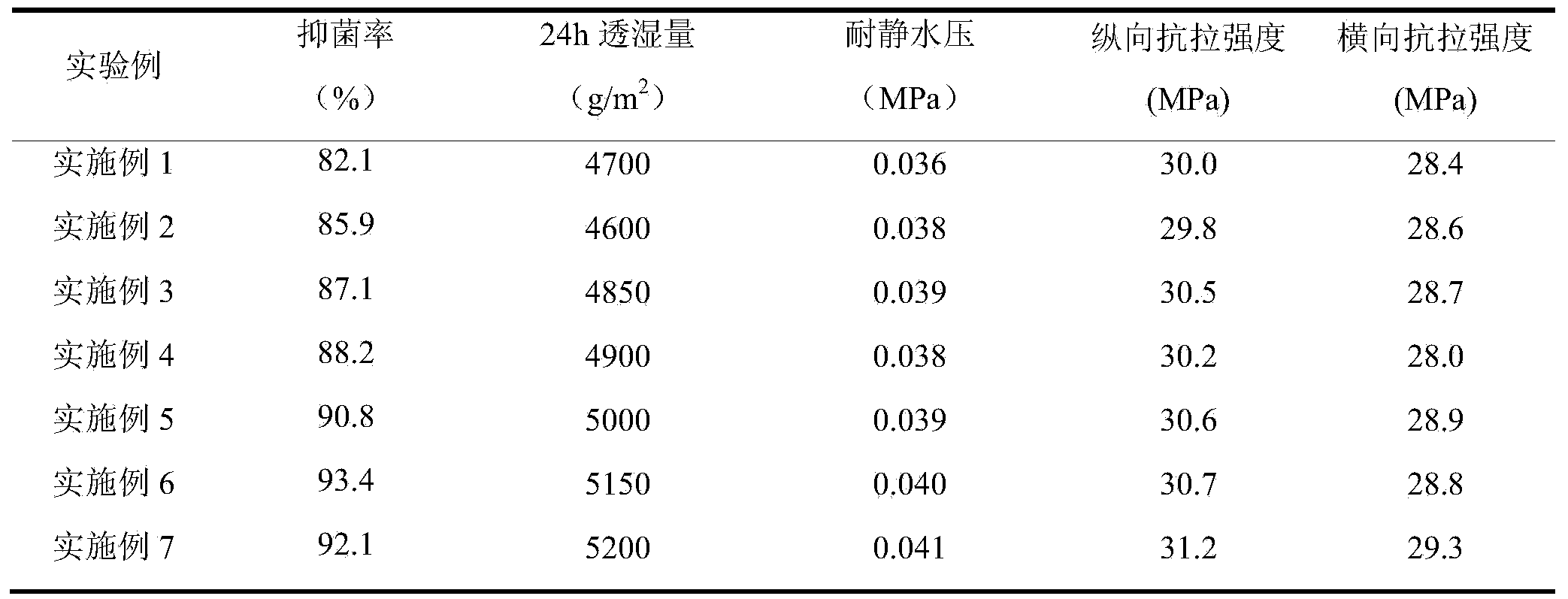

Embodiment 1

[0030] Embodiment 1: at first, with the mass meter of aqueous polyurethane resin 10% bamboo charcoal powder, 4% nano-titanium dioxide and KH570 (gamma-methacryloxypropyltrimethoxysilane) that accounts for 6% of nano-titanium dioxide quality General trade name) in an organic solvent composed of 15% methyl ethyl ketone, 25% toluene and 25% N,N-dimethylformamide based on the quality of water-based polyurethane resin, and ultrasonically dispersed for 5 minutes to prepare a loaded nano-slurry. Next, 1% of the OK-412 matting powder based on the mass of the water-based polyurethane resin was added to the above-mentioned loaded nano-slurry, and a mixed solution was formed under the stirring of a high-speed mixer at 2500 rpm. And the water-based polyurethane resin is fully mixed with 0.4% ZBJ-002 and 0.4% ZBJ-003 based on the mass of the water-based polyurethane resin under the stirring of a mixer with a rotation speed of 1000rpm to form a mixed resin. Then, add the mixed solution to t...

Embodiment 2

[0031] Embodiment 2: at first, with the mass meter of water-based polyurethane resin 15% bamboo charcoal powder, 5.5% nano-titanium dioxide and KH550 (the general brand name of gamma-aminopropyltriethoxysilane) that accounts for 7% of nano-titanium dioxide quality Based on the quality of water-based polyurethane resin, the organic solvent composed of 20% methyl ethyl ketone, 15% toluene and 35% N,N-dimethylformamide was ultrasonically dispersed for 6 minutes to prepare the loaded nano slurry. Next, 2% of the OK-412 matting powder based on the mass of the water-based polyurethane resin was added to the above-mentioned loaded nano-slurry, and a mixed solution was formed under the stirring of a high-speed mixer at 2800 rpm. And the water-based polyurethane resin is fully mixed with 0.6% ZBJ-002 and 0.6% ZBJ-003 based on the mass of the water-based polyurethane resin under the stirring of a mixer with a rotation speed of 1200rpm to form a mixed resin. Then, according to the additi...

Embodiment 3

[0032]Embodiment 3: at first, with the mass meter of waterborne polyurethane resin 20% bamboo charcoal powder, 6% nano-titanium dioxide and KH560 (γ-glycidyl ether oxypropyl trimethoxysiloxane) accounting for 8% of nano-titanium dioxide quality General trade name) was ultrasonically dispersed for 7 minutes in an organic solvent composed of 20% methyl ethyl ketone, 15% toluene and 35% N,N-dimethylformamide based on the quality of water-based polyurethane resin to prepare a loaded nano-slurry. Next, 1% of the OK-412 matting powder based on the mass of the water-based polyurethane resin was added to the above-mentioned loaded nano-slurry, and a mixed solution was formed under the stirring of a high-speed mixer at 3000 rpm. And the water-based polyurethane resin is fully mixed with 0.45% ZBJ-002 and 0.4% ZBJ-003 based on the mass of the water-based polyurethane resin under the stirring of a mixer with a rotation speed of 1300rpm to form a mixed resin. Then, according to the additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com