A kind of preparation method of cross-linked polyacrylonitrile fiber

A polyacrylonitrile fiber and irradiation technology, which is applied in fiber treatment, textiles and papermaking, physical treatment, etc., can solve the problems of polyacrylonitrile fiber strength reduction, improve crosslinking degree, weaken radiation oxidation degradation, weaken oxidation The effect of degree of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Irradiation

[0032] Put the polyacrylonitrile fiber sample into three irradiation tubes, evacuate to 100Pa, seal, and then pass oxygen to make the pressure reach 2×10 4 Pa, put in cobalt source and irradiate to 45kGy, 90kGy, 135kGy respectively at room temperature.

[0033] 2. Determination of gel content

[0034] Weigh 1g of the above-mentioned irradiated polyacrylonitrile fiber, wrap it with filter paper and put it into a net made of 100 mesh stainless steel. After weighing, immerse it in pure dimethyl sulfoxide solvent and dissolve it at 80°C for 24h ; Then use methanol to extract the sample for 12 hours, put the sample in a vacuum oven for 24 hours at 60°C, dry it for 24 hours, take it out and cool it to room temperature, and weigh it; then repeat the above steps until the quality of the sample does not change. Calculate the gel content according to formula (1).

[0035] 3. Heat treatment

[0036] 1g of the above-mentioned irradiated polyacrylonitrile fibers...

Embodiment 2

[0042] 1. Irradiation

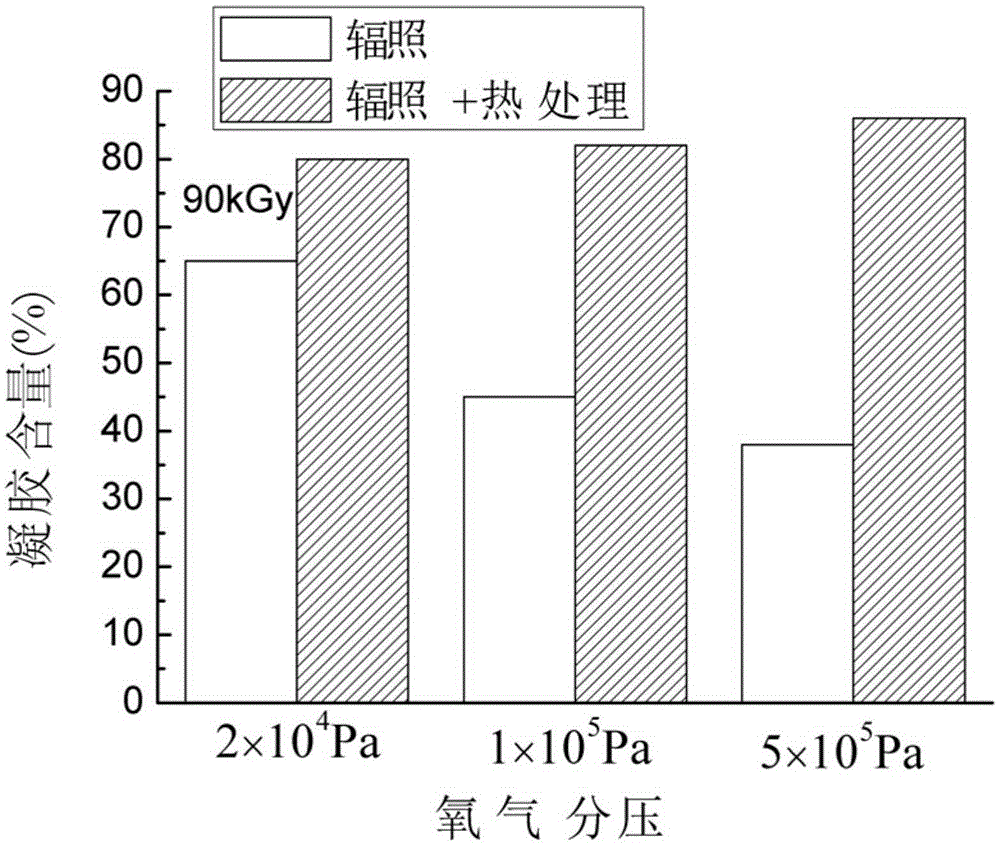

[0043] Put the polyacrylonitrile fiber sample into three irradiation tubes, evacuate to 100pa, seal, and then feed oxygen to make the pressure reach 2×10 4 Pa, 1×10 5 Pa, 5×10 5 Pa, put in a cobalt source and irradiate to 90kGy at a dose rate of 0.5Gy / s at room temperature.

[0044] 2. Determination of gel content

[0045] Weigh 1g of the above-mentioned irradiated polyacrylonitrile fiber, wrap it with filter paper and put it into a basket made of 100-mesh stainless steel mesh. After weighing, immerse it in pure dimethyl sulfoxide solvent and dissolve it at 80°C 24h; then use methanol to extract the sample for 12h, put the sample in a vacuum oven at 60°C and dry for 24h, take it out and cool it to room temperature, and weigh it; then repeat the above steps until the quality of the sample no longer changes. Calculate the gel content according to formula (1).

[0046] 3. Heat treatment

[0047] 1 g of the above-mentioned irradiated polyacrylonitrile...

Embodiment 3

[0053] 1. Irradiation

[0054] Put the polyacrylonitrile fiber sample into the irradiation tube, evacuate to 100pa, seal it, and then feed oxygen to make the pressure reach 1×10 4 Pa and 1×10 6 Put Pa into the cobalt source and irradiate to 500kGy and 10kGy respectively at room temperature.

[0055] 2. Determination of gel content

[0056] Weigh 1g of the above-mentioned irradiated polyacrylonitrile fiber, wrap it with filter paper and put it into a basket made of 100-mesh stainless steel mesh. After weighing, immerse it in pure dimethyl sulfoxide solvent and dissolve it at 80°C 24h; then use methanol to extract the sample for 12h, put the sample in a vacuum oven at 60°C and dry for 24h, take it out and cool it to room temperature, and weigh it; then repeat the above steps until the quality of the sample no longer changes. Calculate the gel content according to formula (1).

[0057] 3. Heat treatment

[0058] 1g of the above-mentioned irradiated polyacrylonitrile fibers w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com