Gate oxide failure point positioning method

A technology of gate oxide layer and positioning method, which is applied in semiconductor/solid-state device testing/measurement, material analysis by measuring secondary emissions, etc., and can solve positioning dependence, poor positioning accuracy, and success rate of gate oxide layer failure analysis efficiency Low-level problems, to achieve the effect of improving efficiency, improving success rate, and shortening preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

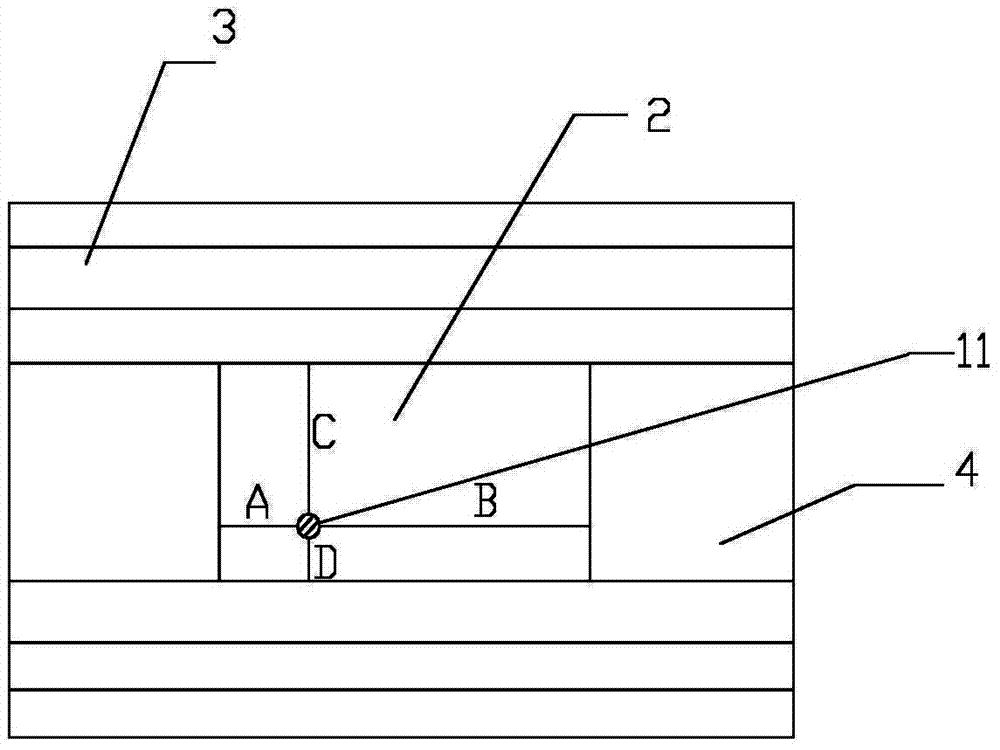

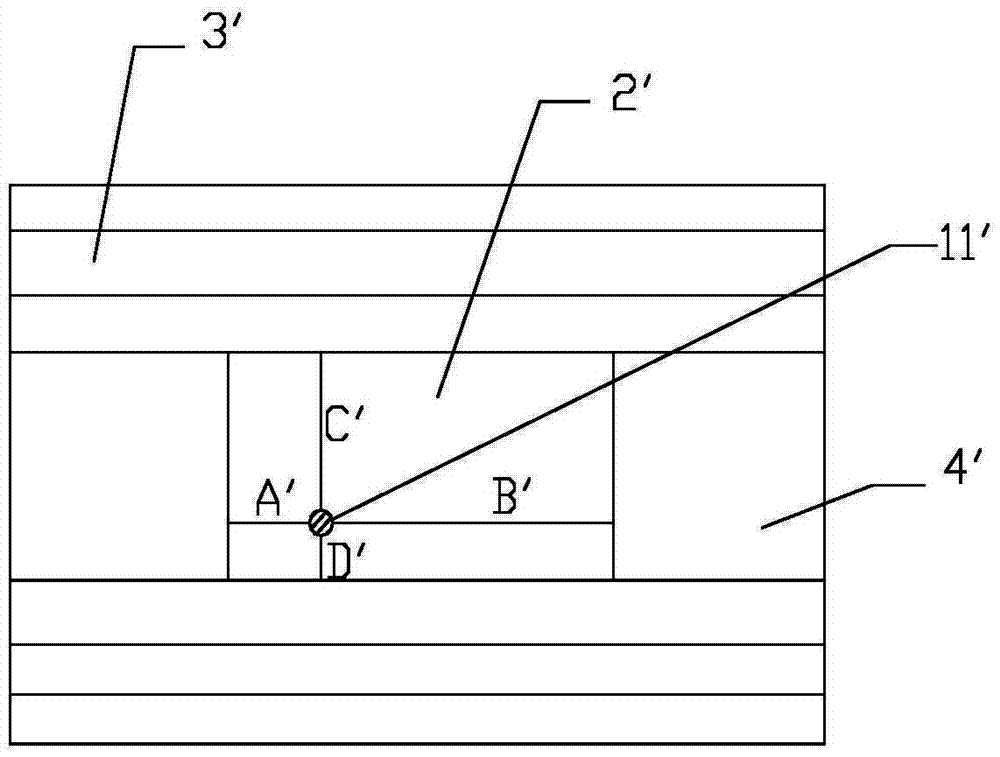

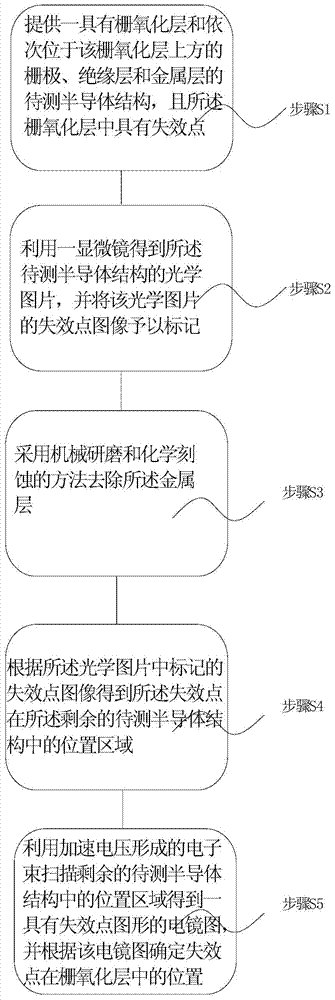

[0045] figure 1 is a schematic diagram of the optical map that uses color to mark the breakdown point of the gate oxide layer, image 3 is a schematic flowchart of a method for locating failure points of a gate oxide layer in an embodiment of the present invention, Figure 4-6 Respectively, in the embodiment of the present invention, a scanning electron microscope detector is used to scan the electron beam formed under the acceleration voltage of 4KV, 10KV, and 20KV to scan the semiconductor structure to be tested after removing the metal layer. Figure 7 It is a schematic diagram of the principle that the electron beam scanning formed by the scanning electron microscope detector under the medium-high speed accelerating voltage can locate the breakdown point in the embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com