Heat sensitive composition and use thereof

A heat-sensitive composition and composition technology, applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment, can solve the problems of shortening the service life of printing plates, eroding image areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

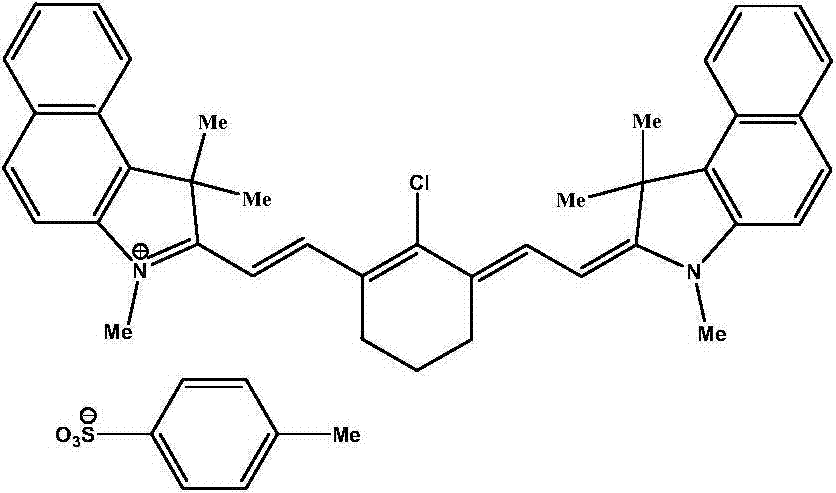

Image

Examples

example

[0052] Abbreviations used below are defined as follows:

[0053] GPC: gel permeation chromatography (Gel permeation chromatography)

[0054] DSC: Differential scanning calorimetry

preparation example 1

[0055] Preparation Example 1: (meth)acrylate

[0056]

[0057] Oil phase: 50g methyl methacrylate (Chimei Petrochemical), 10g methacrylic acid (Chimei Petrochemical), 40g lauryl methacrylate (Chimei Petrochemical), 20 grams of benzoyl peroxide (AKZO) and 1 gram of mercaptan (Shanghai Longsheng Chemical Company), and water phase: 200 grams of pure water and 0.6 grams of PVA (Changchun BP-17) are mixed in a ratio of 1:2, dispersed in the reactor at a stirring speed of 160 rpm, and then heated to 80 ° C for The polymerization reaction can be completed after maintaining the temperature for 3 hours, and finally the solid is washed, dehydrated, and dried to obtain 95 g of acrylic solid. (Weight average molecular weight measured by GPC (model: Waters2414RI): 70,000; Tg = 34°C measured by DSC (model: TAQ-100)

Embodiment 1

[0063] A coating composition solution and an aluminum substrate were produced as in Comparative Example 1. In 91.0 grams of 1-methoxyl-2-propanol, dissolve 9.00 grams of Novolak EP6050 (Asahi organic chemicals industry), 0.50 grams of infrared radiation absorbing dye HCD23 (Hayashibara Bio Chemical laboratories (Hayashibara biochemical laboratories)), 0.50 g of tris(p-dimethylaminophenyl) methane (Ultrachem) and 6.00 g of cellulose acetate butyrate (CAB) (Eastman chemical) ) to make a coating composition solution.

[0064] Further testing separately, the weight loss after imaging treatment in the non-exposed area is 0.1g / m 2 , lower than the allowable range (2 ), 1.5g / m remains after developing the exposed area 2 , higher than the allowable range (2 ). And after soaking the above-mentioned substrate coated with the thermosensitive composition in 50% isopropanol aqueous solution for 1 hour, the detection photosensitive layer remains about 1.7g / m 2 . Comparing Example 1, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com