Organic electroluminescence device, and manufacturing method and display device thereof

An electroluminescence device and a luminescence technology, which are applied in the manufacture of organic semiconductor devices, electric solid devices, semiconductor/solid state devices, etc., can solve problems such as inability to extract and emit light beams, increase beam reflection or total reflection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

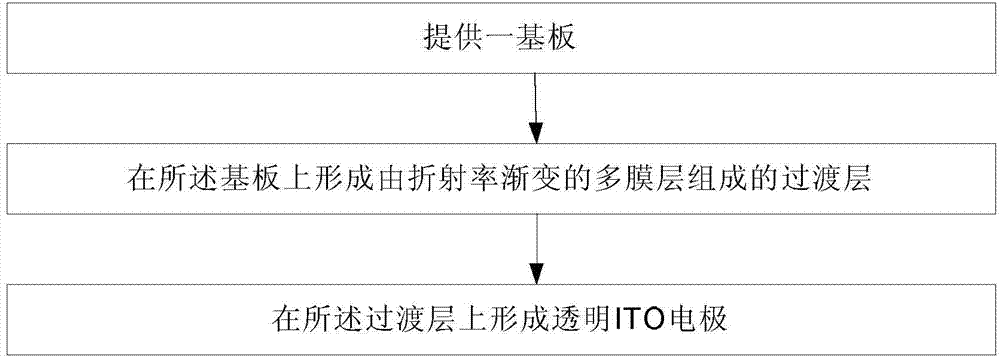

[0044] Another aspect of the present invention also provides a method for preparing an organic electroluminescent device comprising any of the above embodiments, such as figure 2 shown, including:

[0045] 21: Provide a substrate.

[0046] In this step, the substrate may be a glass substrate. It can be understood that the substrate can also be selected from plastic substrates, and it can be further understood that since the refractive index of the plastic substrate is between 1.5-1.65, when the substrate is selected from a plastic substrate, the corresponding bonding is low. The material of the refractive index film layer also needs to be adjusted accordingly to meet the needs of adjusting the refractive index.

[0047] 22: Forming a transition layer composed of multilayer film layers with graded refractive index on the substrate.

[0048] In this step, four small steps can be further included, specifically:

[0049] 1): Mix materials with high and low refractive indices ...

Embodiment 1

[0063] 1) Select polyimide with rigid structure (refractive index greater than 1.8) as high refractive index material, choose flexible polysiloxane (refractive index less than 1.4) as low refractive index material, use tetrahydrofuran and N,N-two Methylacetamide was used as a mixed solvent. Dissolve the above polyimide and polysiloxane in a mixed solvent of tetrahydrofuran and N,N-dimethylacetamide (volume ratio 1:1) according to 50:50wt%, and then put the above mixed solution at room temperature (20°C) and spin-coated on the substrate to form a thin film layer with uniform thickness.

[0064] 2) Utilize the good solubility of polysiloxane in tetrahydrofuran, but the poor solubility in N,N-dimethylacetamide; at the same time, polyimide has good solubility in N,N-dimethylacetamide, Characterized by poor solubility in THF, control the solvent evaporation temperature of the spin-coated film, such as at room temperature (20°C), for phase separation of polyimide and polysiloxane. ...

Embodiment 2

[0069] 1) Select fluorinated polyimide (refractive index greater than 1.8) with rigid structure as high refractive index material, choose flexible polypropylene oxide (refractive index less than 1.4) as low refractive index material, and fluorinated polyimide Amine and polypropylene oxide 60:40wt% are dissolved in an organic solvent, such as dimethyl sulfoxide, and the above organic solution is slit-coated to form a thin film layer with uniform thickness on the surface of the substrate.

[0070] 2) Low-temperature annealing is used to remove the organic solvent (temperature below 100°C) to form an organic dry film. Since the glass transition temperature of fluorinated polyimide is higher than 250°C, the glass transition temperature of polypropylene oxide is lower than 180°C. Utilizing the different glass transition temperatures of the two polymers, the high-temperature annealing temperature was selected to be 200°C (higher than the glass transition temperature of polypropylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com