An energy-saving inverted aao-mbr sewage treatment method

A sewage treatment method and energy-saving technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , waste blast aeration energy consumption and other issues, to achieve the effect of saving aerobic aeration, improving effective utilization, and avoiding ineffective consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

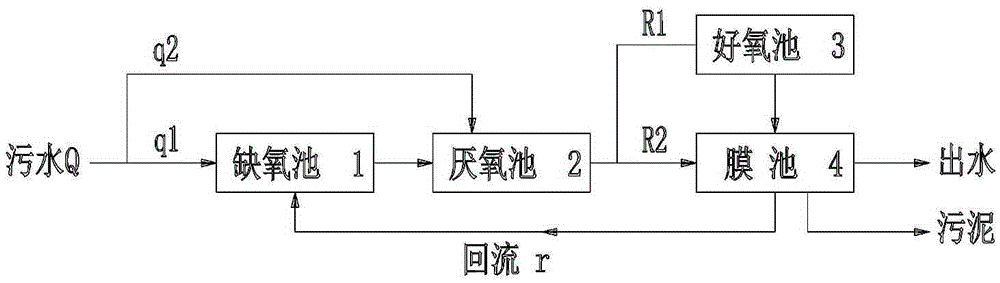

[0027] Combine figure 1 with figure 2 To illustrate, the energy-saving inverted AAO-MBR sewage treatment method provided by the present invention uses a device including an anoxic tank 1, an anaerobic tank 2, an aerobic tank 3, and a membrane tank 4 that are connected to each other.

[0028] The anoxic tank 1 is provided with a first water inlet 11, a first water outlet 12, and a flow thruster 1a. The first water outlet 13 connects the anoxic tank 1 and the anaerobic tank 2;

[0029] The anaerobic tank 2 is provided with a second water inlet 21, a second water outlet 22, a third water outlet 23, a stirrer 2a, and a mixed liquid outlet pipe 2b. The second water outlet 22 connects the anaerobic tank 2 and the aerobic tank 3 The second outlet hole 22 is provided with a first regulating valve 3b; the mixed liquid outlet pipe 2b connects the anaerobic tank 2 and the membrane tank 4 through the third outlet hole 23, and the mixed liquid outlet pipe 2b is provided with a second regulator ...

specific Embodiment approach 2

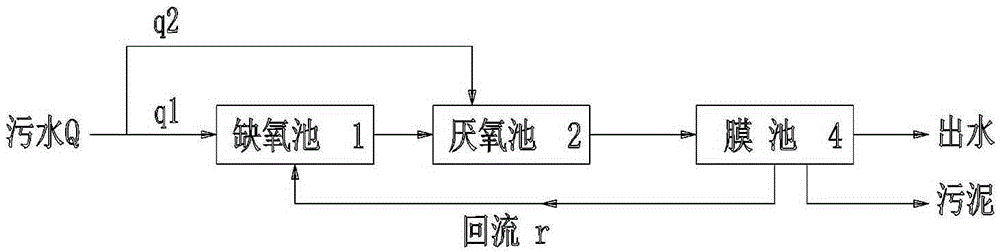

[0037] The difference between this embodiment and the first embodiment is that the first regulating valve 3b and the third regulating valve 4c in the aerobic tank 3 are closed, the aeration device 3a in the aerobic tank 3 is in a stopped state, and the aerobic tank 2 is All the mixed liquid flows into the membrane tank 4 through the third outlet hole 23 and the mixed liquid outlet pipe 2b (ie R2=100%); after pretreatment, the sewage enters the anoxic tank 1 and anaerobic tank 2 (according to the sewage treatment The total amount Q) are respectively q1=0.55Q, q2=0.45Q; the return flow rate of the membrane pool 4 to the anoxic pool 1 is r=7Q. The schematic diagram of the process flow of the second embodiment is shown in image 3 Shown.

[0038] The hydraulic retention time of anoxic tank 1 is 4.0h, the hydraulic retention time of anaerobic tank 2 is 2.0h, the hydraulic retention time of membrane tank 4 is 2.0h, the mixed liquid sludge in anoxic tank 1, anaerobic tank 2 Concentrati...

specific Embodiment approach 3

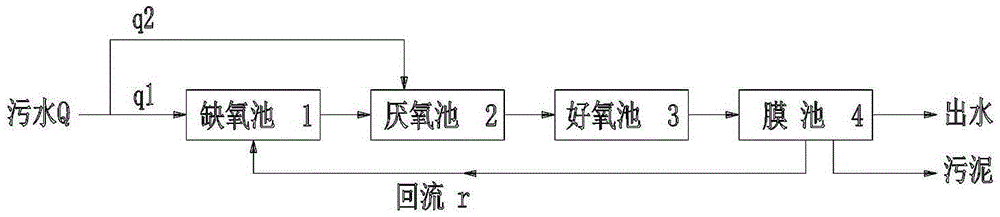

[0041] The difference between this embodiment and the first embodiment is that the second regulating valve 2c in the anaerobic tank 2 is closed, and the amount of sewage entering the anoxic tank 1 and the anaerobic tank 2 after pretreatment (calculated according to the total amount of sewage treatment Q ) Respectively q1=0.6Q, q2=0.4Q; all the mixed liquid in the anaerobic tank 2 flows into the aerobic tank 3 through the second outlet hole 22 and the first regulating valve 3b (ie R1=100%); The sewage treated by the oxygen tank 3 enters the membrane tank 4 from the fourth water outlet 31 and the third regulating valve 4c, and the return flow rate of the membrane tank 4 back to the anoxic tank 1 is r=3Q. The schematic diagram of the process flow of the third embodiment is shown in Figure 4 Shown.

[0042] The hydraulic retention time of anoxic tank 1 is 4.0h, the hydraulic retention time of anaerobic tank 2 is 2.0h, the hydraulic retention time of aerobic tank 3 is 2.5h, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com