A2N-SBR (anaerobic/anoxic/nitrification-sequencing batch reactor) improved deep denitrification and dephosphorization technology of sewage

A deep denitrification and improved technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of low nitrogen and phosphorus removal efficiency, influent C Low /N, high energy consumption and other issues, to achieve the effect of saving COD consumption, reducing sludge production rate and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

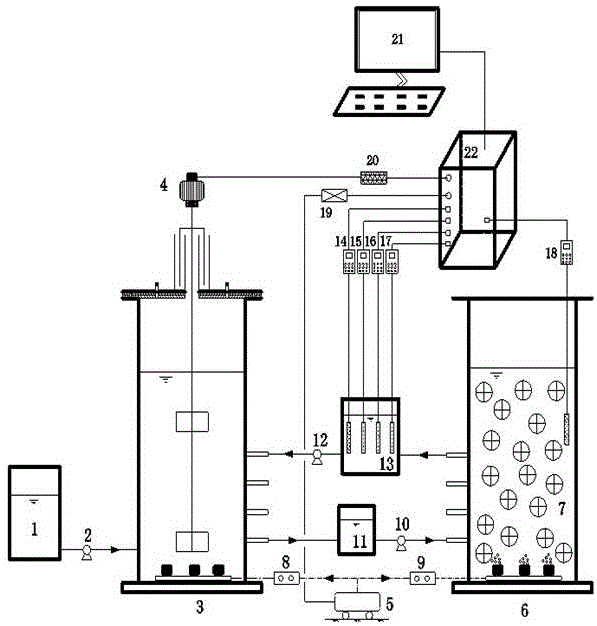

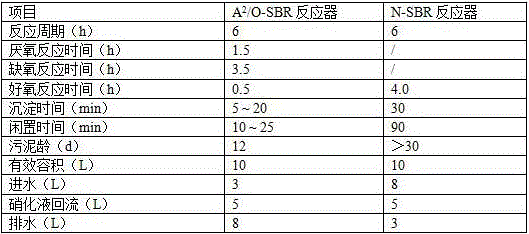

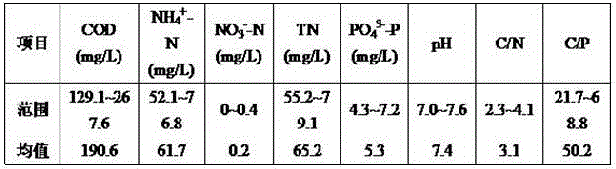

[0021] One, the device of technology of the present invention:

[0022] Such as figure 1 As shown, among them, 1- raw water tank; 2- water inlet pump; 3- A 2 / O-SBR reactor; 4-stirring device; 5-blower; 6-N-SBR reactor; 7-polypropylene suspension packing; 8,9-flow meter; 10-intermediate lift pump ;11-intermediate water tank ;12-Intermediate lift pump ;13-intermediate water tank ;14-NH 4 + Sensor; 15-NO 3 - Sensor; 16-NO 2 - Sensor; 17-TP sensor; 18-DO sensor; 19-flow sensor; 20-speed sensor; 21-computer; 22-online control box.

[0023] A 2 The / O-SBR reactor 3 operates alternately through anaerobic, anoxic and aerobic operations to complete the removal of organic matter and synchronous denitrification and phosphorus removal, and is equipped with a rotational speed sensor 20, which is calculated and output by a computer 21 to adjust the rotational speed of the stirring device 4, Based on the joint control strategy of shortening the settling time and increasing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com