Preparation method for sharp leading edge

A leading edge and sharp technology, applied in the field of sharp leading edge preparation, can solve the problems of difficult weaving sharp leading edge, fiber breakage, needle drop, etc., and achieve the effect of improving erosion resistance, eliminating heat flow concentration, and eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

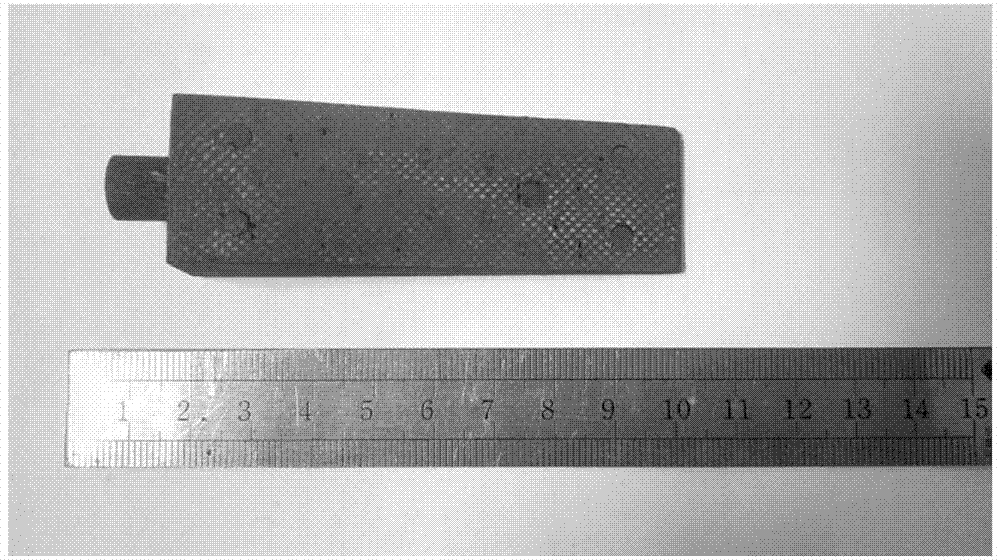

[0029] The leading edge radius is 1.5mm, and the inner core material is a three-dimensional acupuncture C / SiC sharp C / SiC-ZrC leading edge. The preparation steps are as follows:

[0030] Mold preparation: Use graphite material to process the mold according to the design drawing of the front edge. The radius of the front edge of the male mold is R0.5mm, the radius of the inner surface of the female mold is R1.5mm, and the corresponding position of the male mold and female mold has a circular hole with a diameter of 5mm. The leading edge radius is evenly distributed under 15mm from the top.

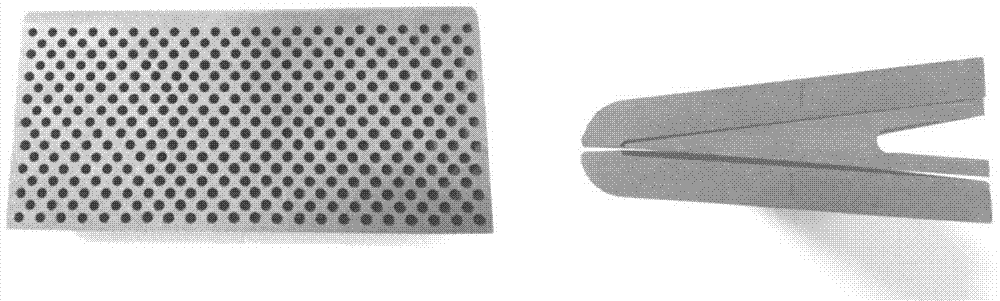

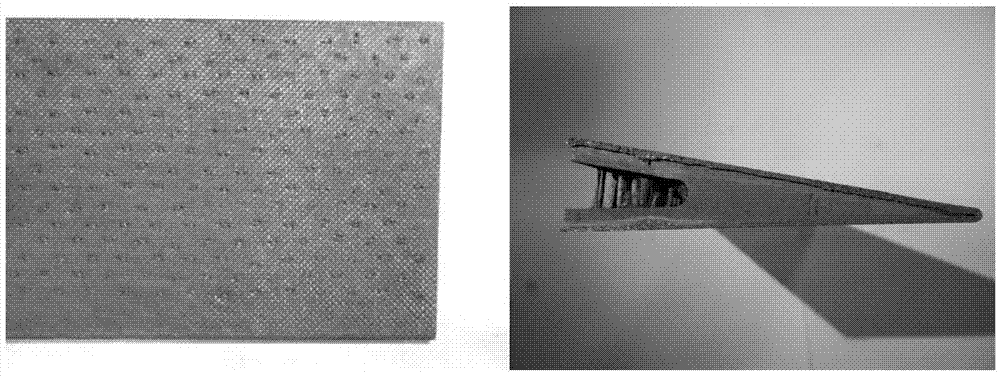

[0031] Preparation of two-dimensional laminated protective layer: Spread 5 layers of carbon fiber cloth evenly on the surface of the male mold, and firmly stitch the carbon cloth with fibers through the holes reserved on the mold. Using CVI process, propylene is pyrolyzed at 960°C to deposit pyrolytic carbon interface phase on the surface of carbon fiber, and MTS is loaded into the deposition fu...

Embodiment 2

[0036] The leading edge radius is 2mm, and the inner core material is a C / SiC leading edge of 3D needled C / SiC. The preparation steps are as follows:

[0037] Mold preparation: Use graphite material to process the mold according to the design drawing of the front edge. The radius of the front edge of the male mold is R1mm, the radius of the inner surface of the female mold is R2mm, and the corresponding position of the male mold and female mold has a circular hole with a diameter of 5mm, and the distance from the top of the front edge radius Evenly distributed under 15mm.

[0038] Preparation of two-dimensional laminated protective layer: Spread 5 layers of carbon fiber cloth evenly on the surface of the male mold, and firmly stitch the carbon cloth with fibers through the holes reserved on the mold. Using CVI process, propylene is pyrolyzed at 960°C to deposit pyrolytic carbon interface phase on the surface of carbon fiber, and MTS is loaded into the deposition furnace with hydrog...

Embodiment 3

[0043] The leading edge radius is 1.5mm, and the inner core material is a C / SiC sharp leading edge with 3D piercing C / SiC. The preparation steps are as follows:

[0044] Mold preparation: Use graphite material to process the mold according to the design drawing of the front edge. The radius of the front edge of the male mold is R0.5mm, the radius of the inner surface of the female mold is R1.5mm, and the corresponding position of the male mold and female mold has a circular hole with a diameter of 5mm. The leading edge radius is evenly distributed under 15mm from the top.

[0045] Preparation of two-dimensional laminated protective layer: Spread 5 layers of carbon fiber cloth evenly on the surface of the male mold, and firmly stitch the carbon cloth with fibers through the holes reserved on the mold. Using CVI process, propylene is pyrolyzed at 960°C to deposit pyrolytic carbon interface phase on the surface of carbon fiber, and MTS is loaded into the deposition furnace with hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com