Idiosyncratic refined HMX (cyclotetramethylene tetranitramine) crystal and preparation method thereof

A crystal and special technology, which is applied in the field of special refined HMX crystal and preparation, can solve the problems that HMX cannot be directly applied, and achieve the effect of less anti-solvent consumption, mild reaction conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

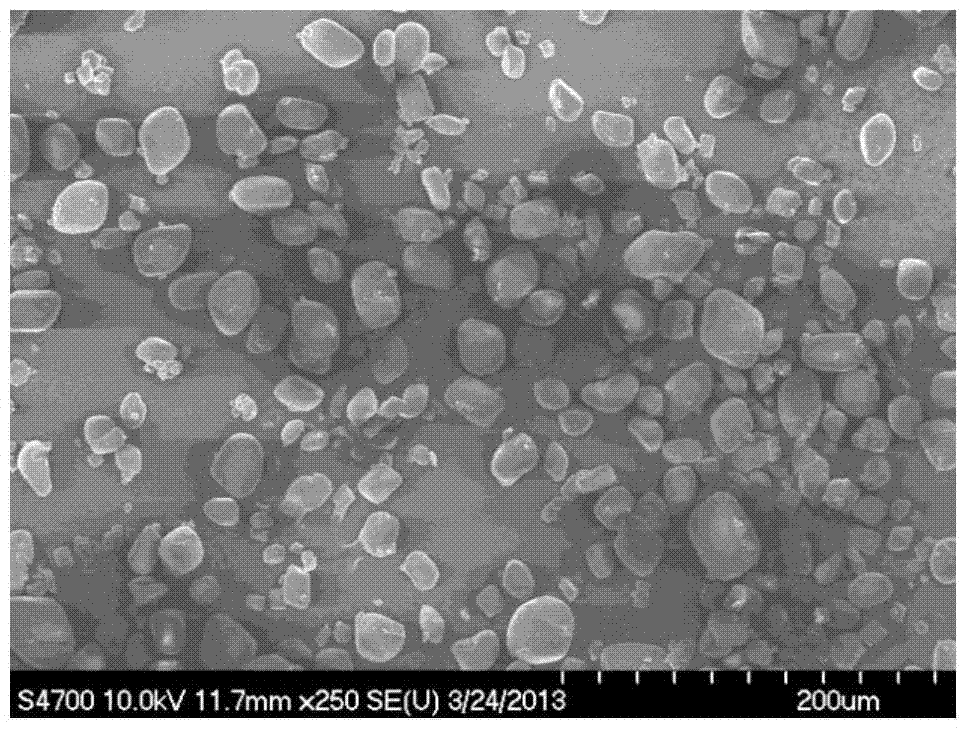

[0036] 5 g of HMX was dissolved in 9 mL of dimethyl sulfoxide, and the solution was filtered into a 100 mL reactor, which was placed in a constant temperature water bath at 35°C. Turn on the stirrer, the stirring rate is 100rpm, and start the dripping device to add ethanol dropwise to the reaction kettle at the rate of 0.1mL / min. The total amount of ethanol used was 45mL, and after all the addition was completed, the crystals were subjected to ultrasonic treatment in the mother liquor, the ultrasonic frequency was 45KHz, and the ultrasonic time was 2h. Wash, filter, dry, and weigh. The crystal weight is about 4.6 g, and the yield is 92%. According to the experimental determination, the HMX content is ≥99.9%; the density is 1.901g / cm 3 ; The appearance has no sharp edges and corners, the surface is smooth, and the crystal surface has no cracks; the ratio of the short and long axis of the crystal is 0.83; the median particle size of the precipitated crystal is 16 μm, and the p...

Embodiment 2

[0038] Dissolve 10 grams of HMX in 18 mL of dimethyl sulfoxide, filter the solution into a 150 mL reactor, and the reactor is placed in a constant temperature water bath at 30°C. Turn on the stirrer, the stirring rate is 80rpm, and start the dripping device to drip chloroform into the reaction kettle at the same time, the dropping rate is 0.16mL / min. The total amount of chloroform used was 90 mL. After all the drops were completed, the crystals were ultrasonically treated in the mother liquor. The ultrasonic frequency was 36 KHz and the ultrasonic time was 3 h. Wash, filter, dry, and weigh. The crystal weight is about 9.1 g, and the yield is 91%. According to the experimental determination, the HMX content is ≥99.9%; the density is 1.90g / cm 3 ; The appearance has no sharp edges and corners, the surface is smooth, and the crystal surface has no cracks; the ratio of the short and long axis of the crystal is 0.8; the median particle size of the precipitated crystal is 20 μm, an...

Embodiment 3

[0040] 5 g of HMX was dissolved in 9 mL of dimethyl sulfoxide, and the solution was filtered into a 100 mL reactor, which was placed in a constant temperature water bath at 35°C. Turn on the stirrer, the stirring rate is 100rpm, and start the dripping device to drip chloroform into the reaction kettle at the same time, the dripping rate is 0.4mL / min. The total amount of chloroform used was 45mL. After all the drops were completed, the crystals were subjected to ultrasonic treatment in the mother liquor, the ultrasonic frequency was 42KHz, and the ultrasonic time was 2h. Wash, filter, dry, and weigh. The crystal weight is about 4.5 g, and the yield is 90%. According to the experimental determination, the HMX content is ≥99.9%; the density is 1.901g / cm 3 ; The appearance has no sharp edges and corners, the surface is smooth, and the crystal surface has no cracks; the ratio of the short and long axis of the crystal is 0.81; the median particle size of the precipitated crystal i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com