ABS (acrylonitrile-butadiene-styrene) plastic for automobile inner ornaments and preparation method thereof

A technology for ABS plastics and automotive interior parts, applied in the field of ABS plastics for automotive interior parts and its preparation, can solve the problems of poor light aging resistance and easy yellowing of plastic materials, and achieve good formability and good yellowing resistance The effect of sex change

Active Publication Date: 2014-07-23

SHANDONG HANSHI AUTOMOTIVE COMPONENTS

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the current technology, plastic materials are usually used for automotive interior parts, but conventional plastic materials are prone to yellowing and have poor light aging resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4

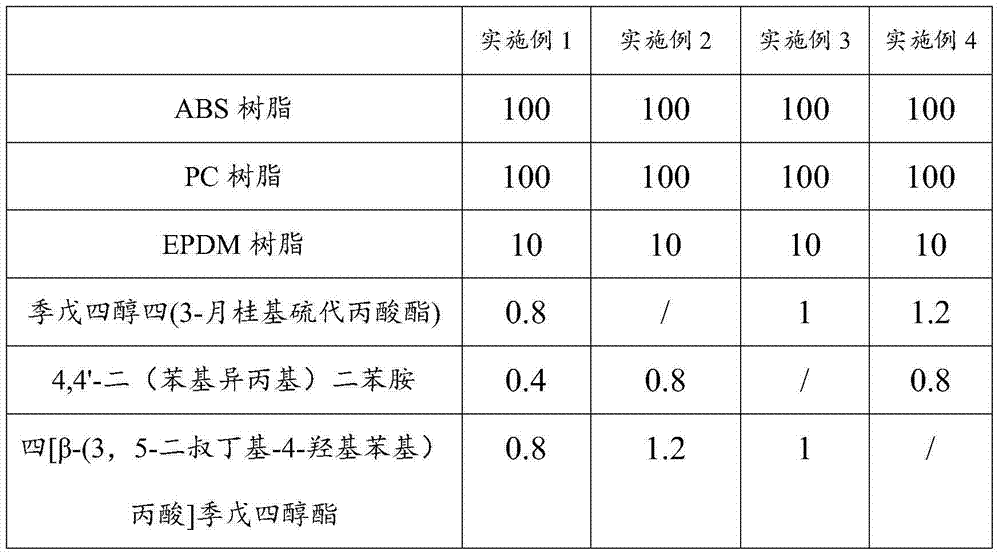

[0015] Each raw material was weighed according to the data corresponding to Examples 1-4 in Table 1. After uniform mixing, melt kneading, extruding and granulating to obtain the ABS plastic for automotive interior parts.

[0016] Table 1: Formula table of ABS plastics for automotive interior parts Unit: kg

[0017]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an ABS (acrylonitrile-butadiene-styrene) plastic for automobile inner ornaments and a preparation method thereof. The ABS plastic for automobile inner ornaments comprises the following components in parts by weight: 100 parts of ABS resin, 80-120 parts of PC (polycarbonate) resin, 5-15 parts of EPDM (ethylene-propylene-diene monomer) resin and 1-3 parts of anti-yellowing agent. The preparation method comprises the following steps: proportionally weighing the raw materials, uniformly mixing, melting and compounding, and extruding and granulating. The ABS plastic for automobile inner ornaments has the advantages of favorable formability, favorable mechanical properties, high impact strength, high temperature resistance, favorable ultraviolet resistance, favorable light aging resistance and the like, and can be used for preparing automobile inner ornaments by an injection molding technique.

Description

technical field [0001] The invention relates to a plastic material and a preparation method thereof, in particular to an ABS plastic for automotive interior parts and a preparation method thereof. Background technique [0002] Automotive interior parts, English name: Automotive Interior, mainly refers to the automotive products used in the interior modification of the car, involving all aspects of the car interior, such as glove boxes, car seat back panels, car inlay panels, car side panels, pillar guards Panels, door panels, car sub-dashboards, glove boxes, radio boxes and center consoles are all automotive interior products. The automotive interior system is an important part of the car body, and the design workload of the interior system accounts for more than 60% of the car styling design workload, far exceeding the car shape, and is one of the most important parts of the car body. [0003] In the current technology, plastic materials are usually used for automotive int...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L55/02C08L69/00C08L23/16C08K5/18C08K5/134C08K5/372

Inventor 陈斌张荣福印玲谢庆利

Owner SHANDONG HANSHI AUTOMOTIVE COMPONENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com