A kind of spherical nano aramid fiber material and preparation method thereof

A kind of aramid fiber and nano technology, which is applied in the field of new spherical nano aramid fiber material to achieve the effect of low cost, suitable for large-scale process production and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Under the protection of nitrogen, 0.2 grams of poly-p-phenylene terephthalamide short fibers and 0.1107 grams of potassium hydroxide were added to 100 milliliters of anhydrous dimethyl sulfoxide, and mechanically stirred at room temperature for 3 to 5 days until the reaction was complete to obtain Dark red aramid nanosol. Bottled and sealed, it is a spherical nano-aramid fiber material with a weight percentage of 1.82%.

Embodiment 2

[0016] Under the protection of nitrogen, add 0.2 grams of poly-p-phenylene terephthalamide short fibers and 0.2214 grams of potassium hydroxide to 100 milliliters of dimethyl sulfoxide, and stir mechanically at room temperature for 3 to 5 days until the reaction is complete, and a dark red color is obtained. Aramid nano sol. Bottled and sealed, it is a spherical nano-aramid fiber material with a weight percentage of 1.80%.

Embodiment 3

[0018] Under the protection of nitrogen, add 0.2 grams of poly-p-phenylene terephthalamide short fibers and 0.3184 grams of potassium hydroxide to 100 milliliters of dimethyl sulfoxide, and stir mechanically at room temperature for 3 to 5 days until the reaction is complete, and a dark red color is obtained. Aramid Nano Solution. Bottled and sealed, it is a spherical nano-aramid fiber material with a weight percentage of 1.78%.

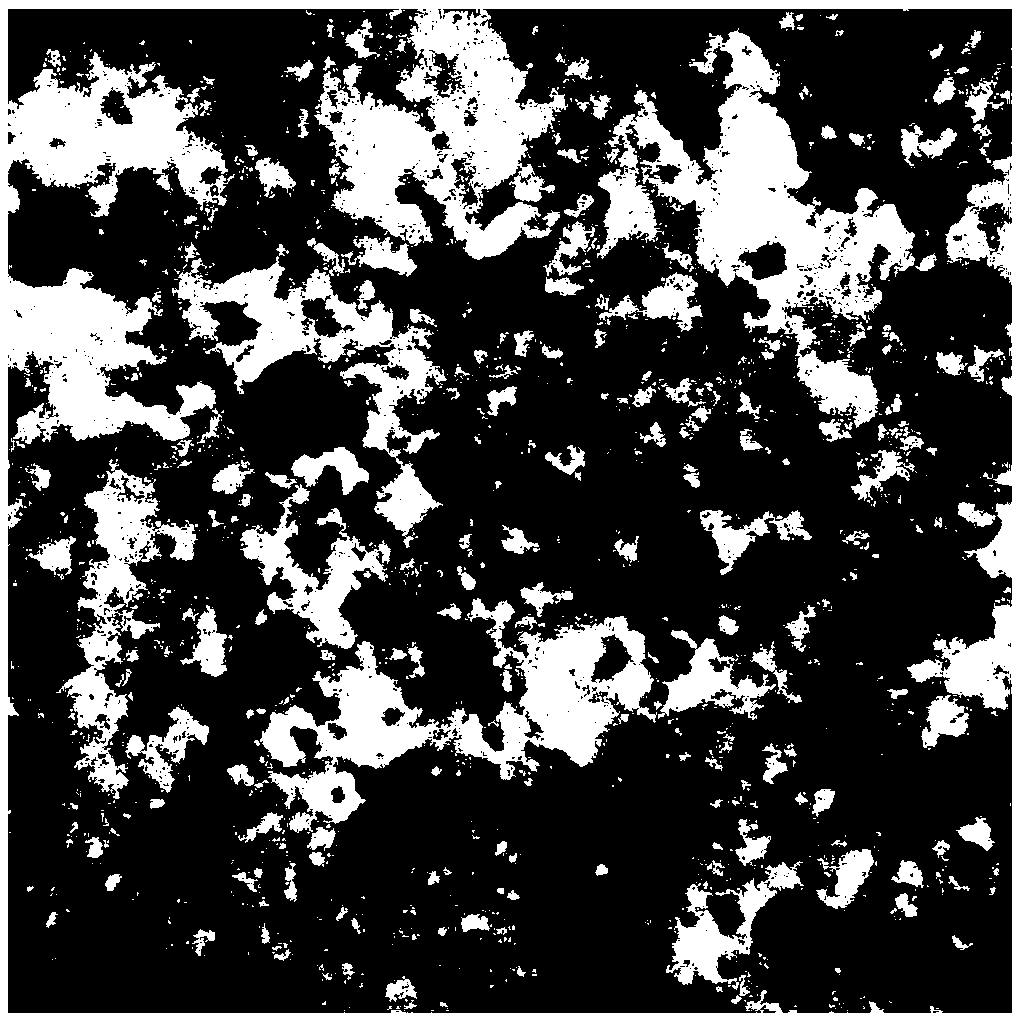

[0019] Such as figure 1 Shown is the transmission electron microscope image of the novel spherical nano-aramid fiber material prepared by the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com