Thermal insulation finish paint, preparation and applications thereof

A technology of topcoat and heat preservation, applied in coating and other directions, can solve the problem that the heat insulation mechanism is contrary to the overall planning and construction of the city, and achieve the effect of good weather resistance and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation of embodiment 1 tert-acrylic emulsion

[0050] method one:

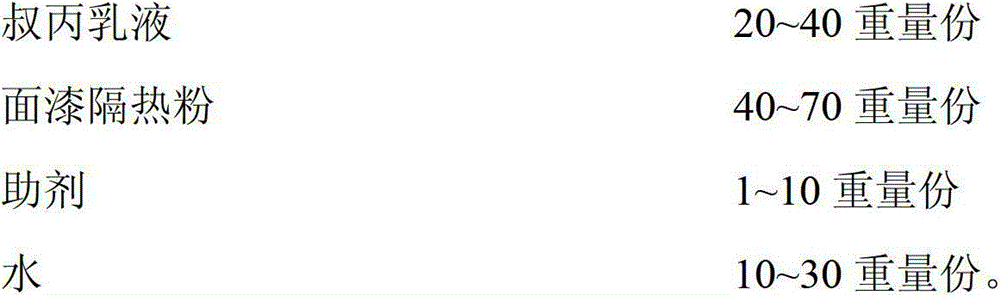

[0051] 1) Raw material composition of raw materials in the nuclear department

[0052]

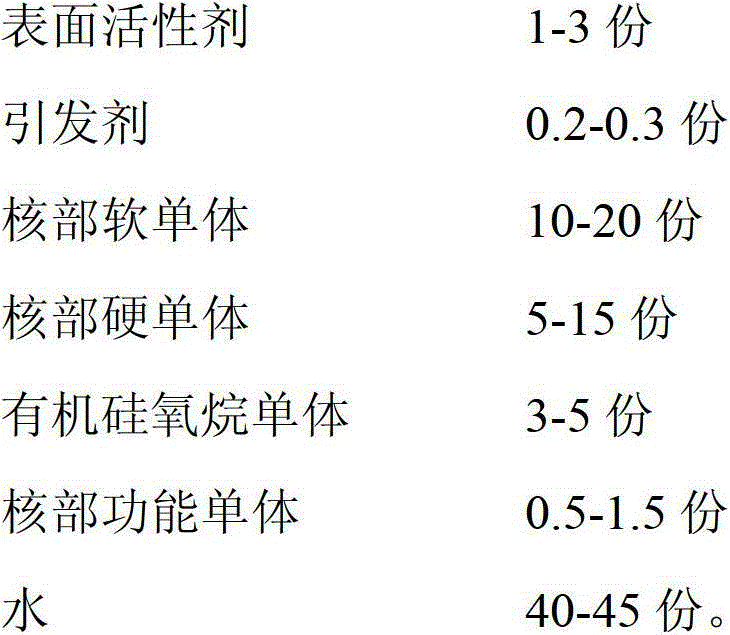

[0053] 2) Composition of shell raw materials

[0054]

[0055] Preparation:

[0056] In the raw material components of the above-mentioned core part, 2 / 3 mass of deionized water, 1 / 3 mass of surfactant, 1 / 3 mass of initiator, 1 / 4 mass of core part soft monomer, 1 / 6 mass The core hard monomer, 1 / 4 mass core functional monomer, and 1 / 6 mass organosiloxane monomer are added to the reactor, and the temperature is raised to 80°C under stirring conditions for 10 minutes to form a seed nanometer. Crystal emulsion, and then mix the raw materials of the remaining part in the raw material composition of the nuclear part to obtain the pre-emulsion of the nuclear layer; add the pre-emulsion of the nuclear layer dropwise to the seed nanocrystal emulsion of the reactor, and the dropping time is 3 hours. During ...

Embodiment 2

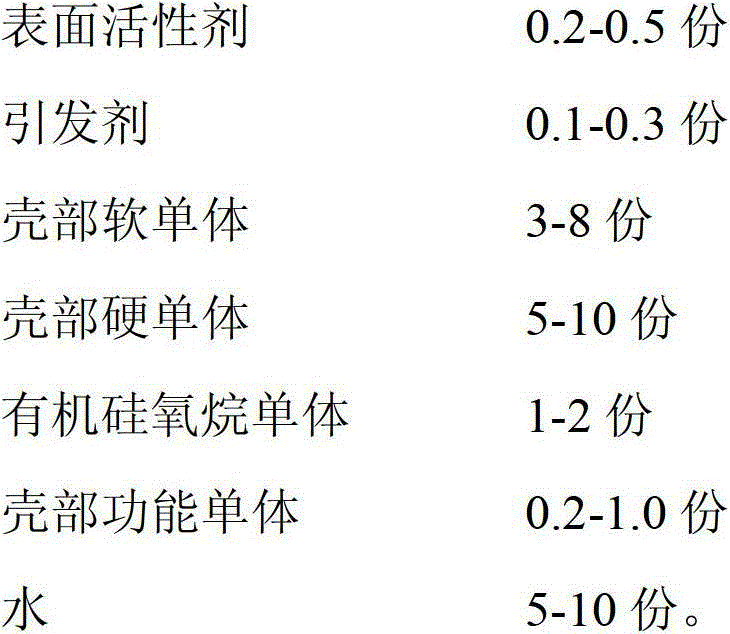

[0076] Preparation and performance testing of embodiment 2 thermal insulation topcoat

[0077] 1. Reagents

[0078] Dispersant S-70S is provided by Shanghai Zhongcheng Chemical Co., Ltd.; dispersant 2320 is provided by Shenzhen Haichuan Co., Ltd.; wetting agent LB407 and wetting agent EFS4070 are provided by Shanghai Zhongcheng Chemical Co., Ltd.; hydrophilic defoamer is The defoamer 315 was provided by Shenzhen Haichuan Co., Ltd.; the hydrophobic defoamer was defoamer DF538, provided by Shanghai Zhongcheng Chemical Co., Ltd. 4A molecular sieve was provided by Luoyang Jianlong Co., Ltd. Saiboya nano rubber powder is provided by Yuhang Jiacheng Nonmetal Mining Co., Ltd. Leveling agent LEV-202, provided by Shanghai Zhongcheng Chemical Co., Ltd. The pH regulator AP-95 was provided by Shanghai Zhongcheng Chemical Co., Ltd. Fungicide 515 was provided by Shanghai Chaoling Co., Ltd. Antifungal agent A2W, provided by Shanghai Chaoling Co., Ltd. Wetting agent: EFS-4070 is provide...

experiment example

[0116] Experimental example: the thermal insulation topcoat prepared by method 1-4 of Example 2 of the present invention.

[0117] 2) Experimental method:

[0118] Experimental content: Test the actual thermal conductivity of the topcoat after construction and maintenance

[0119] Experimental basis: GB / T10297-2008 "The heat flow meter method for the determination of the steady-state thermal resistance and related characteristics of thermal insulation materials"

[0120] 3) Experimental results

[0121] Table 2 Test results of thermal conductivity of thermal insulation finish paint

[0122] method 1

[0123] The preparation of the thermal insulation topcoat of the present invention is the first time. The thermal insulation coatings on the market with similar functions to those of the present invention are reflective thermal insulation coatings, but the existing reflective thermal insulation coatings are only white, while the thermal insulation topcoat of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com