Special braided copper alloy wire for fishing nets for marine enclosure culture and preparation method thereof

A copper alloy and colonization technology, which is applied in the field of braided copper alloy wire for marine colonization fishing nets and its preparation, can solve problems such as difficult forming, corrosion resistance, damage to the braiding machine, etc., to achieve easy weaving, quality protection, and improvement The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A special braided copper alloy wire rod for marine enclosure fishing nets, which adopts the following technological process:

[0020] Batching—melting—casting—extrusion—stretching—annealing and pickling—drying—stretching—inspection—packing—storage

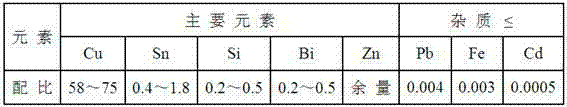

[0021] 1. Batching: it is the core technology of the present invention, the most critical process for the success of the invention. Its chemical composition is as follows:

[0022] Table 1 Chemical composition of braided copper alloy wires for marine fishnets (%)

[0023]

[0024] 2. Melting: In a power frequency induction copper melting furnace, melt the prepared charge into a qualified copper liquid (chemical composition meets the requirements in Table 1, and the temperature is 1030°C).

[0025] 3. Casting: The casting slab is pulled by a horizontal continuous casting machine, coiled to a weight of about one ton, and removed from the shelf.

[0026] 4. Extrusion: 300-type continuous extrusion machine is used to proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com