A gravel/sand filter layer-porous concrete pile composite foundation and its treatment method

A porous concrete and composite foundation technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of porous concrete losing its water permeability function, porous concrete prone to segregation, and unsatisfactory drainage effect of piles, etc., to achieve pore connectivity Good effect, moderate plastic viscosity and small yield stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A certain project is located in the alluvial plain of the Yellow River, which belongs to the yellow flood zone. Geological conditions from top to bottom are silt, clay, silt, clay. The groundwater level is about 3m, and the groundwater is very abundant. In order to reduce the post-construction settlement and ensure the stability of the building, the design uses gravel / sand filter layer-porous concrete pile composite foundation to treat the soft soil foundation.

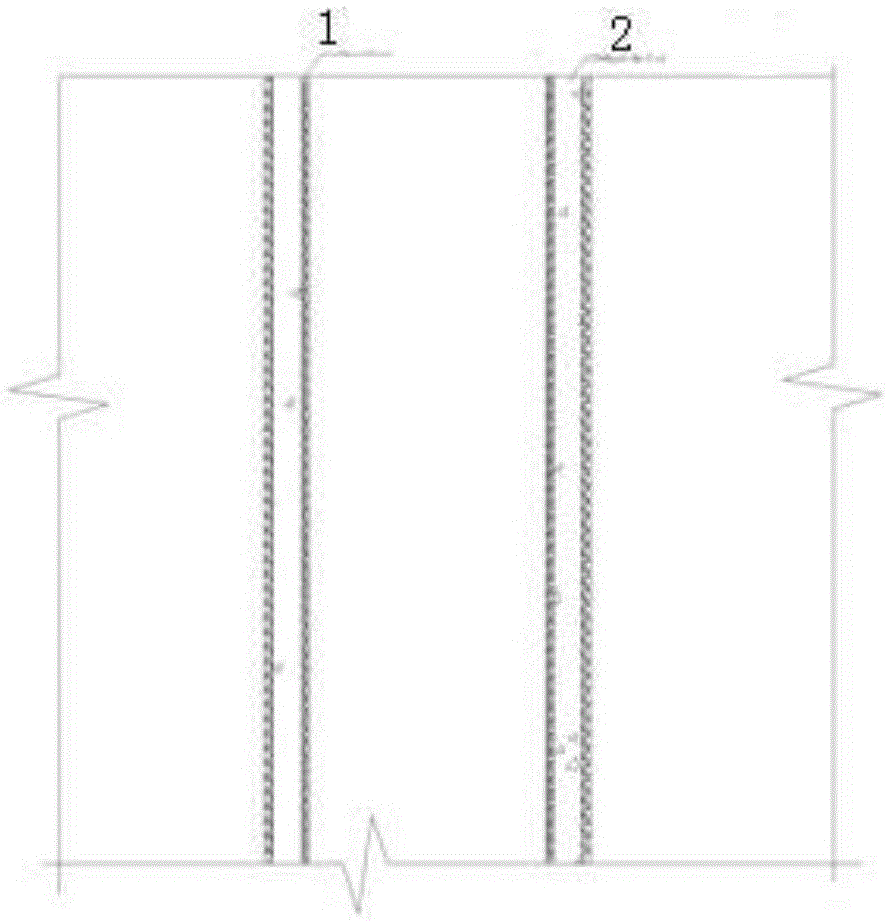

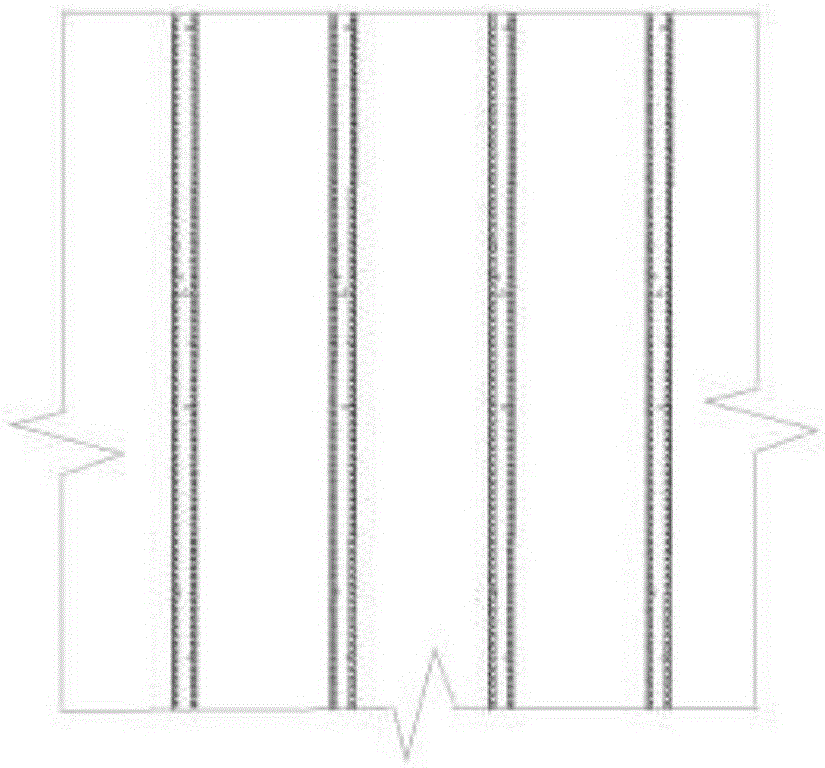

[0056] Such as figure 1 , 2 As shown, a gravel / sand filter layer-porous concrete pile composite foundation includes a pile body, and the outside of the pile body is a gravel / sand filter layer, and the gravel / sand filter layer can prevent mud from penetrating into the porous concrete pile , without losing drainage. The interior is made of porous concrete material, which ensures water permeability and has a certain strength and rigidity, which is conducive to increasing the speed of pipe removal, reducing di...

Embodiment 2

[0066] A project uses gravel / sand filter layer-porous concrete pile composite foundation for treatment.

[0067] A gravel / sand filter layer-porous concrete pile composite foundation, which includes a pile body, and the outside of the pile body is a gravel / sand filter layer, and the gravel / sand filter layer can prevent mud from penetrating into the porous concrete pile, while not Loss of drainage. The interior is made of porous concrete material, which ensures water permeability and has a certain strength and rigidity, which is conducive to increasing the speed of pipe removal, reducing disturbance to the soil around the pile, and improving the bearing capacity of the composite foundation. A gravel / sand filter combined with a porous concrete material forms a composite foundation.

[0068] The foundation treatment steps are as follows:

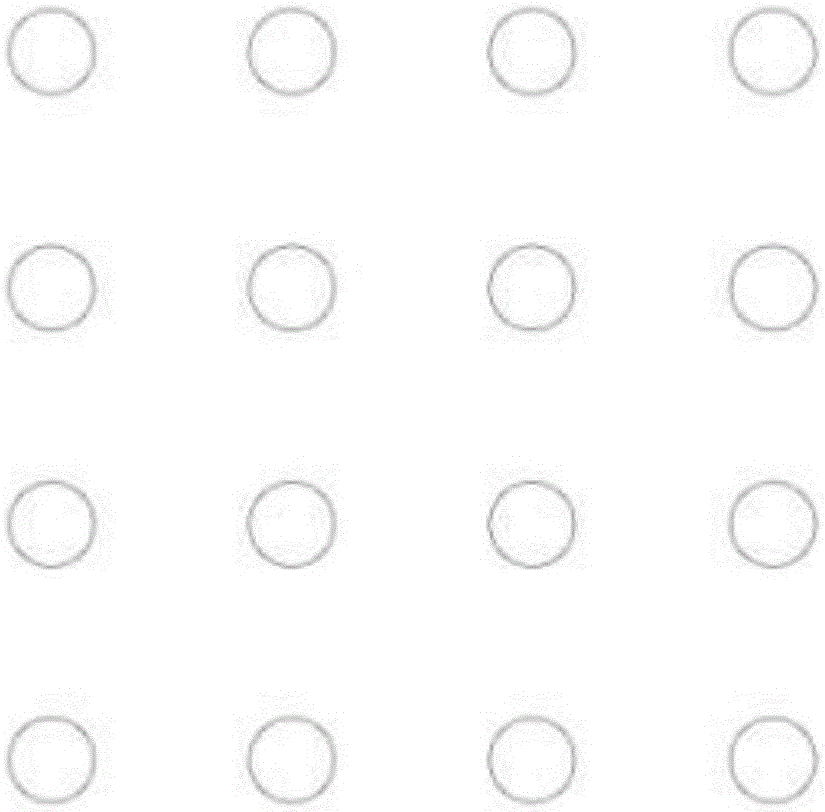

[0069] The piles are arranged in a square image 3 As shown, according to the mechanical construction conditions, the pile diameter is 0.3m,...

Embodiment 3

[0077] A project design uses gravel / sand filter layer-porous concrete pile composite foundation to treat the foundation.

[0078] A gravel / sand filter layer-porous concrete pile composite foundation, which includes a pile body, and the outside of the pile body is a gravel / sand filter layer, and the gravel / sand filter layer can prevent mud from penetrating into the porous concrete pile, while not Loss of drainage. The interior is made of porous concrete material, which ensures water permeability and has a certain strength and rigidity, which is conducive to increasing the speed of pipe removal, reducing disturbance to the soil around the pile, and improving the bearing capacity of the composite foundation. A gravel / sand filter combined with a porous concrete material forms a composite foundation.

[0079] The foundation treatment steps are as follows:

[0080] The piles are arranged in a square image 3 As shown, according to the mechanical construction conditions, the pile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com