Anti-overshock method of anti-shock magneto-rheological buffer

A magnetorheological buffer and over-impact technology, applied in the field of buffers, can solve the problems of no platform effect, time response lag of magnetorheological buffers, large impact force peaks, etc., to reduce equipment and software design costs, eliminate Hysteresis, the effect of avoiding impact force peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

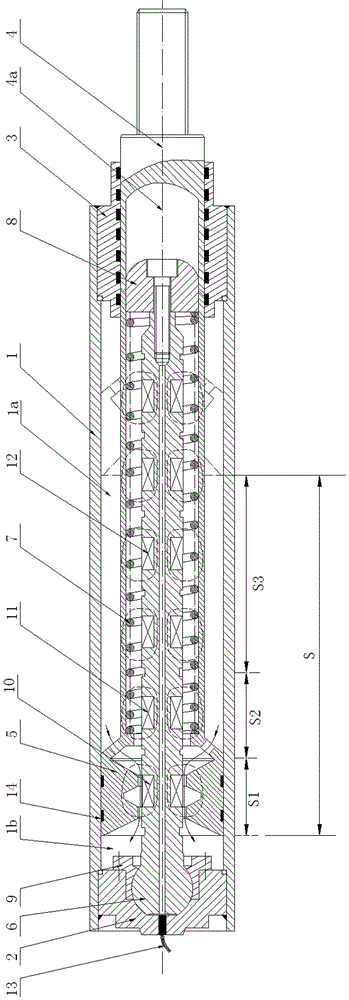

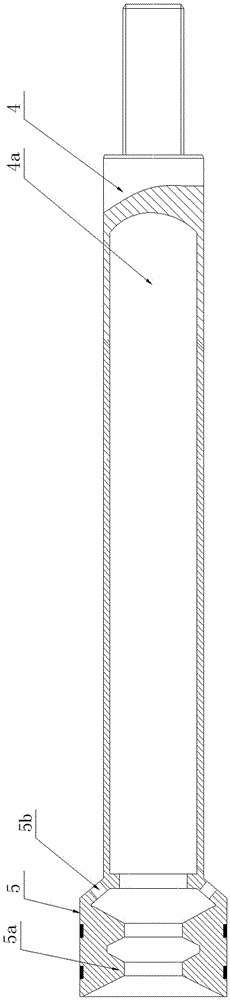

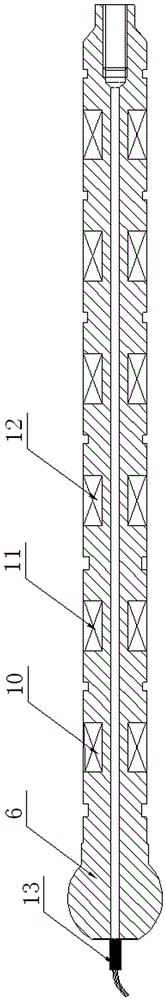

[0026] see Figure 1 to Figure 3 , an anti-overshock method of an anti-shock magneto-rheological buffer, which uses an anti-shock magneto-rheological buffer to control over-shock in high-strength impact environment equipment, and the anti-shock magneto-rheological buffer includes a piston rod 4 and Cylinder 1, the two ends of the cylinder 1 are respectively provided with a sealing end seat 2 and a sealing end cover 3, forming a closed cavity, and the closed cavity is filled with magnetorheological fluid. The sealing end seat 2 and the sealing end cover 3 are welded to both ends of the cylinder 1 respectively. A seal 14 is provided between the sealing end seat 2 , the sealing end cover 3 and the cylinder 1 respectively. Described piston rod 4 is provided with cavity 4a, and this cavity 4a is provided with return spring 7, and the mouth of cavity 4a of described piston rod 4 is provided with piston damping ring 5, and cylinder barrel 1 gap fits, and cylinder barrel The airtigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com