Forecasting method of material fatigue threshold value under different stress ratios

A prediction method and stress ratio technology, applied in the field of fatigue crack growth, can solve the problems of heavy test workload, complicated measurement procedures, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Prediction of Cr-Mo-V Steel Fatigue Threshold for a Certain Rotor

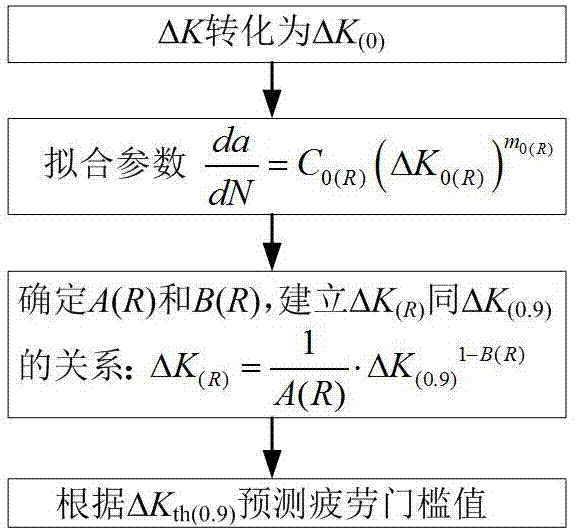

[0044] After quenching a certain rotor with Cr-Mo-V steel, the tempering heat treatment system is 580°×10h. Using compact tensile specimens, the fatigue threshold test at room temperature was carried out by the load-reduction method, and the fatigue crack growth data at R=0.1, 0.3, 0.5, 0.7, and 0.9 were obtained. The specific steps for predicting the fatigue threshold are as follows (see figure 1 ):

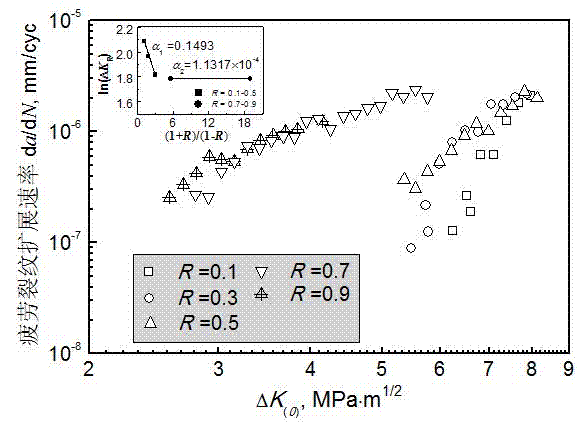

[0045] (1) Convert ΔK under various stress ratios to R=0 equivalent stress intensity factor range ΔK (0) , to obtain da / dN-ΔK (0) relationship (such as figure 2 shown). At the same time, calculate da / dN=1×10 -6 α value under high and low R at mm / cyc, where, when R≥0.7, α=α 2 =1.1317×10 -4 ; while for R-4 .

[0046] (2) Fit the C and m values in the Paris formula according to the linear relationship in the log-log coordinates (see Table 1).

[0047] Table 1. C and m values in the Pa...

Embodiment 2

[0055] Example 2 Prediction of Fatigue Threshold Value of Cr-Mo-V Steel for a Certain Rotor After Adjusting Tempering Heat Treatment System

[0056] In order to improve the quenching and tempering properties of the Cr-Mo-V steel used for a certain rotor in Example 1, after quenching the Cr-Mo-V steel used for a certain rotor in Example 1, the tempering heat treatment system was adjusted to 580 ° × 40h, Then predict the fatigue threshold, the specific steps are as follows:

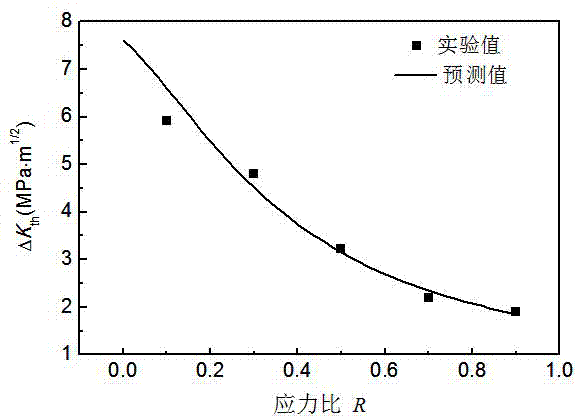

[0057] (1) Carry out the fatigue threshold test under R=0.9 to get the fatigue threshold ΔK th,(0.9) 2.29MPa·m 1 / 2 ; Compared with the original heat treatment, the fatigue threshold increased by 20% after the tempering temperature was increased.

[0058] (2) In the prediction, it is considered that: in ΔK (R) with ΔK (0.9) In the relationship, A(R) and B(R) have little change, that is, the relationship between A(R) and B(R) and R is still:

[0059] A(R)=0.14+0.24R+0.83R 2 ,

[0060] B(R)=0.9-R.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com