Device for selectively filtering light rays

A light-filtering and selective technology, applied in the direction of optical filters, optics, optical components, etc., can solve the problems of eye discomfort, insufficient blue light of the filtered LCD screen, eye damage, etc., and achieve the effect of reducing eye fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A lens for selectively filtering light, comprising:

[0052]

[0053] The production method of the lens for selectively filtering light is preferably:

[0054] Step 1, mix KY55, KA50-3A, ultraviolet absorber UV-41 and colorant at a temperature of 50-70°C, and cool down to below 30°C after the ultraviolet absorber and colorant are completely dissolved;

[0055] Step 2, add the azo initiator V-65, after mixing, stop heating and stand still for 12-36h;

[0056] Step 3, evacuate to -0.1MPa, keep the temperature of the material at 25±1°C, and implement the filling operation.

[0057] After the lens is heated and cured, it is hardened (WH-10 type hardened liquid of DON company in South Korea) and vacuum coated. The coating parameters are:

[0058]

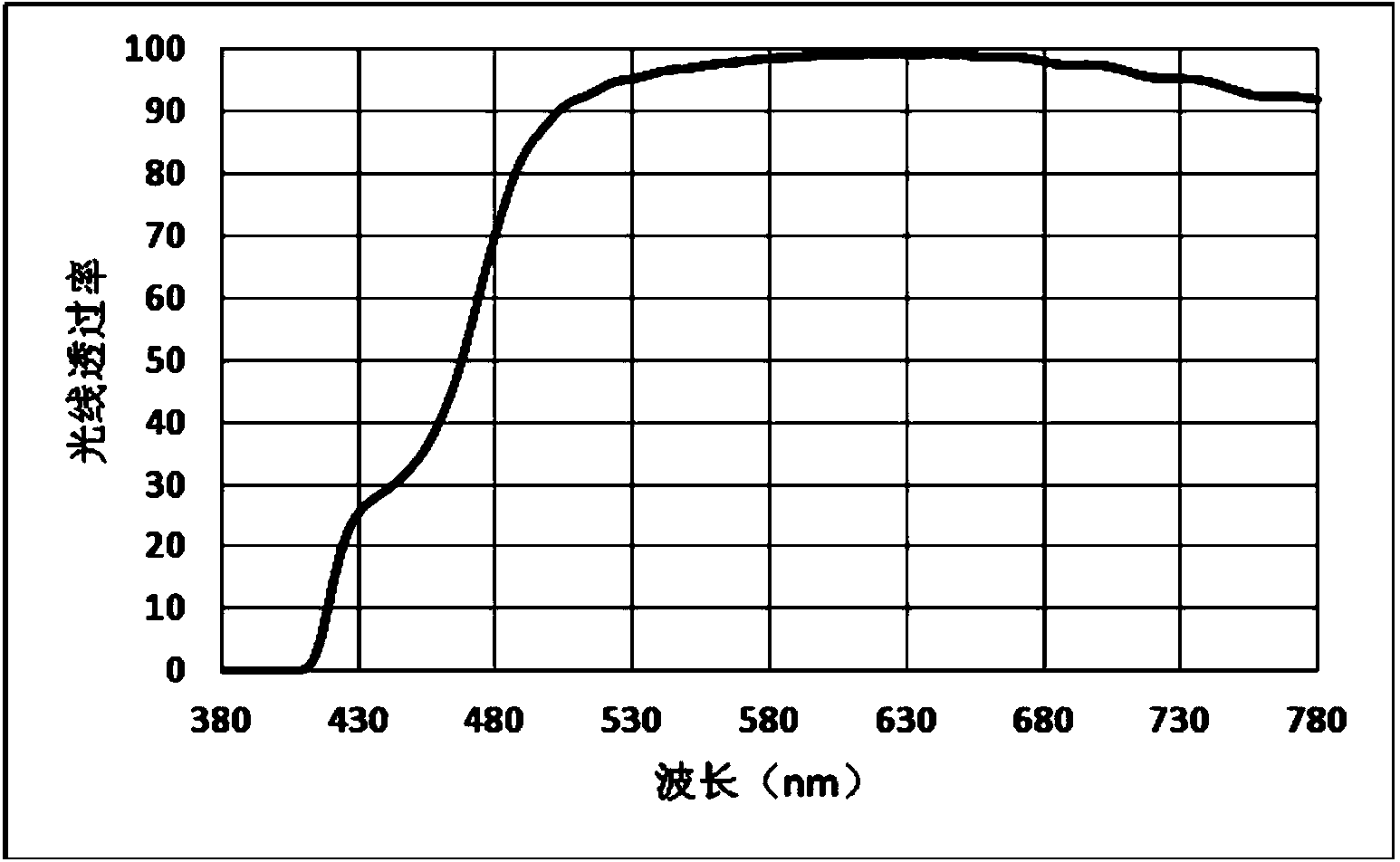

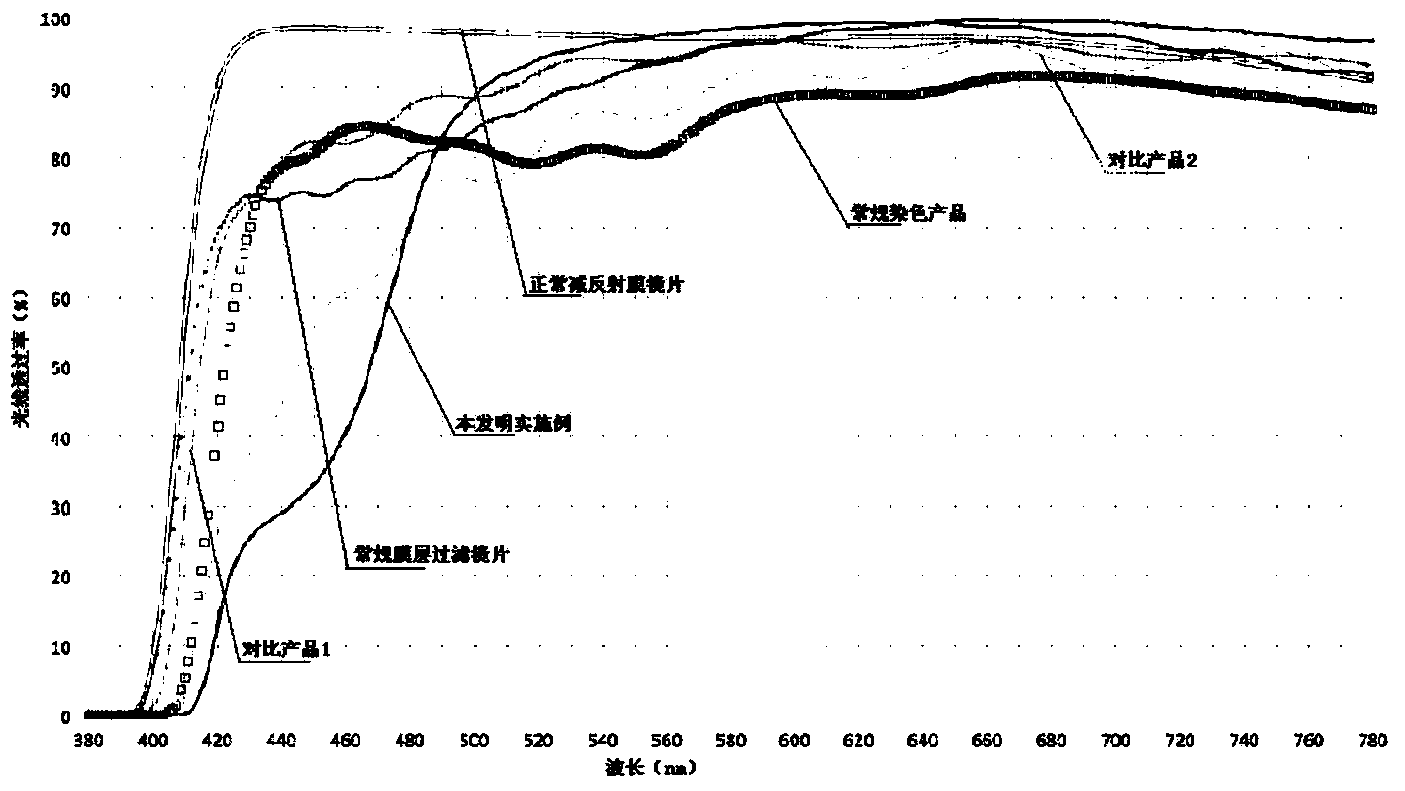

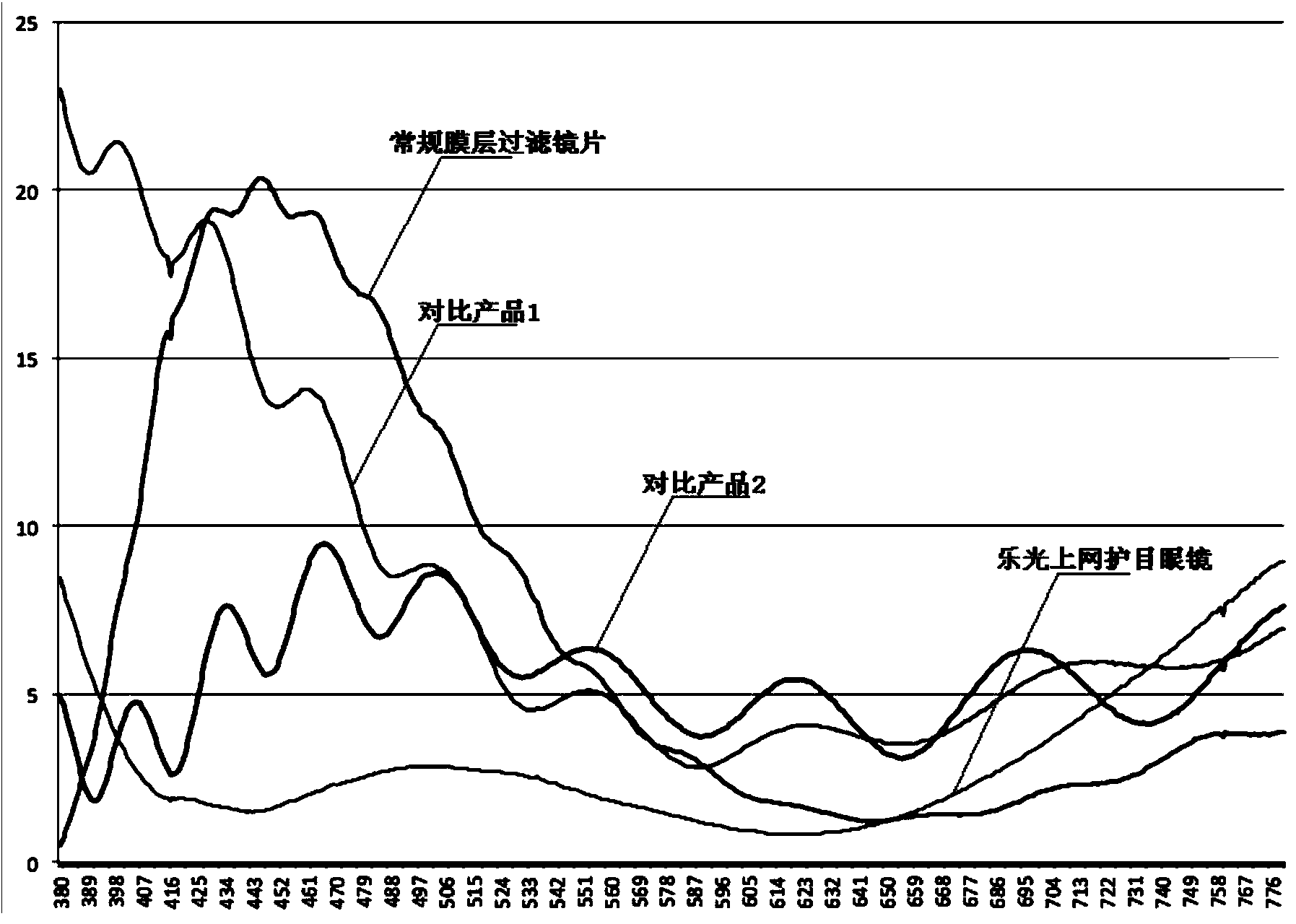

[0059] According to the method steps described in the above-mentioned examples, the optical lens for selectively filtering light is 2.2mm in thickness, which is detected by the spectrophotometer UV-2450 produced by Japan S...

Embodiment 2

[0061] A lens for selectively filtering light, comprising:

[0062]

[0063] The production method of the lens for selectively filtering light is preferably:

[0064] Step 1, mix MR-8A, UV absorber and colorant at a temperature of 40-60°C, and cool down to below 20°C after the UV absorber and colorant are completely dissolved;

[0065] Step 2, add MR-8B1, MR-8B2, and photoinitiator DBC (provided by Mitsui), after mixing, stop heating and stand still for 12 hours;

[0066] Step 3, evacuate to -0.1MPa, keep the temperature of the material at 15±1°C, and implement the filling operation.

[0067] After the lens is heated and cured, it is hardened (WH-10 type hardened liquid of DON company in South Korea) and vacuum coated. The coating parameters are:

[0068]

[0069] According to the eyeglass of the selective filtering light that above-mentioned embodiment gains, thickness is 2.2mm, through the spectrophotometer UV-2450 that Japanese shimadzu company produces detects, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com