High-power semiconductor laser optical shaping method and device based on beam expanding

An optical shaping and semiconductor technology, applied in the field of laser applications, can solve the problems of small spot size compression ratio, uneven energy, short working distance, etc., and achieve the effect of increasing the size of the light-emitting surface, uniform energy distribution, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

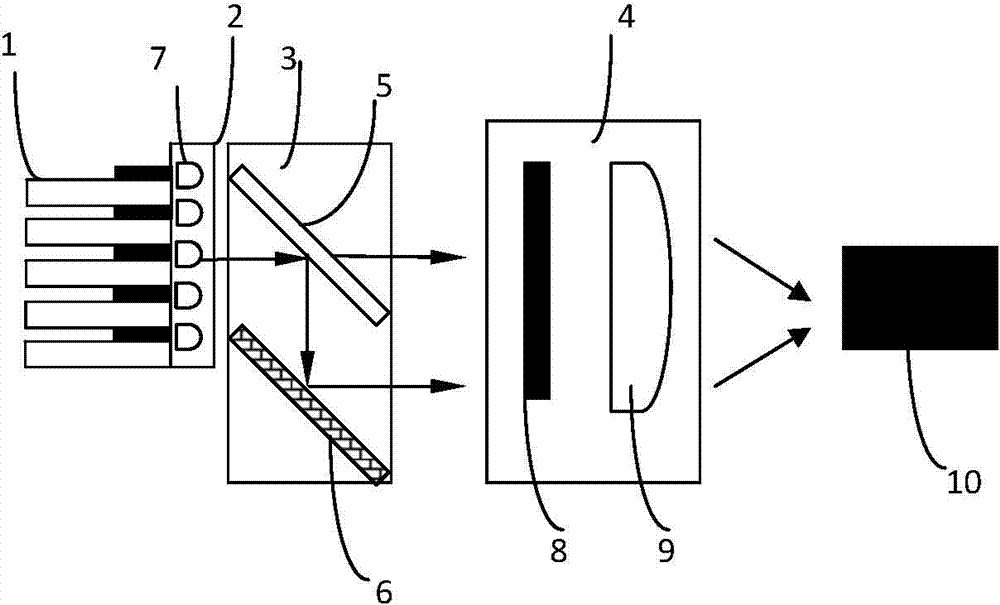

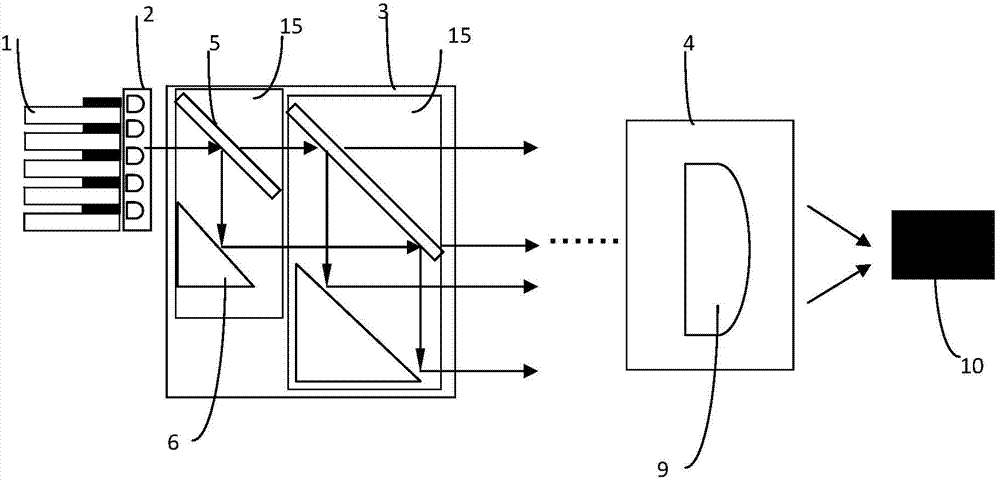

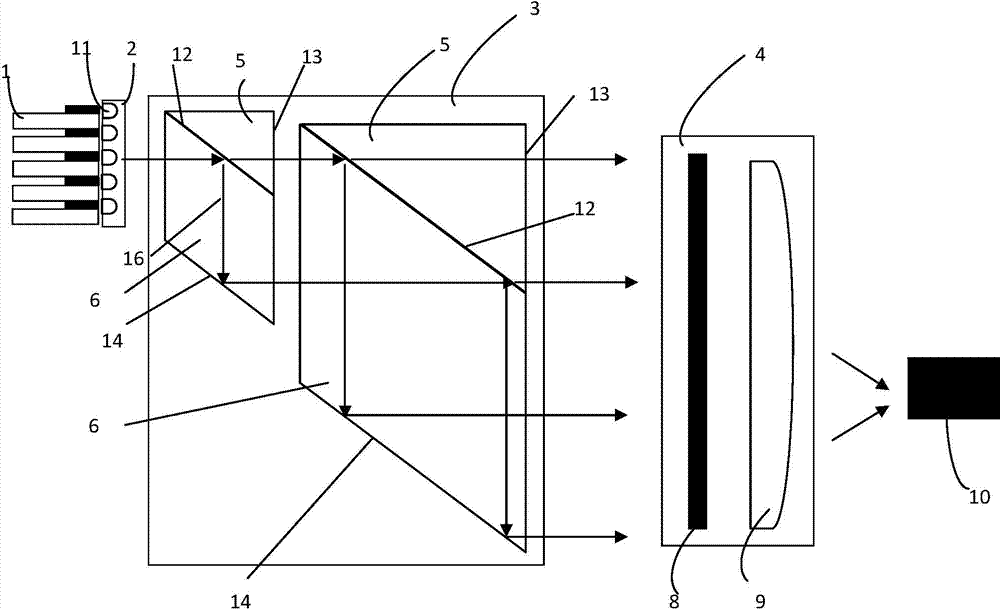

[0049] Such as figure 1 The high-power semiconductor laser optical device based on beam expansion includes a semiconductor laser stack 1, a collimating lens group 2, a beam splitting system 3 and a focusing system 4.

[0050] The semiconductor laser stack 1 is composed of several semiconductor laser units; the collimating lens group 2 is placed at the laser exit of the semiconductor laser; The collimated laser beam is expanded; the focusing system 4 is used to focus and shape the expanded laser beam.

[0051] Optical splitting system 3 includes n component optical modules, such as figure 1 As shown, in this embodiment, it is a group of optical modules, the optical module includes a beam splitter 5 and a reflector 6, and the laser light emitted by the laser is incident on the beam splitter 5; the splitting surface of the beam splitter and the reflective surface of the reflector Set parallel to each other along the height direction and form an included angle of 30-60° with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com