Direct current supply system for drilling machine and control method of direct current supply system

A power supply system, DC power supply technology, applied in the parallel operation of DC power supplies, DC network circuit devices, current collectors, etc., can solve the problem of inability to provide a braking energy solution path, large DC energy storage device energy storage, compensation speed and accuracy. and other problems, to achieve the effect of eliminating strict restrictions on output voltage and frequency, reducing energy storage capacity and reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

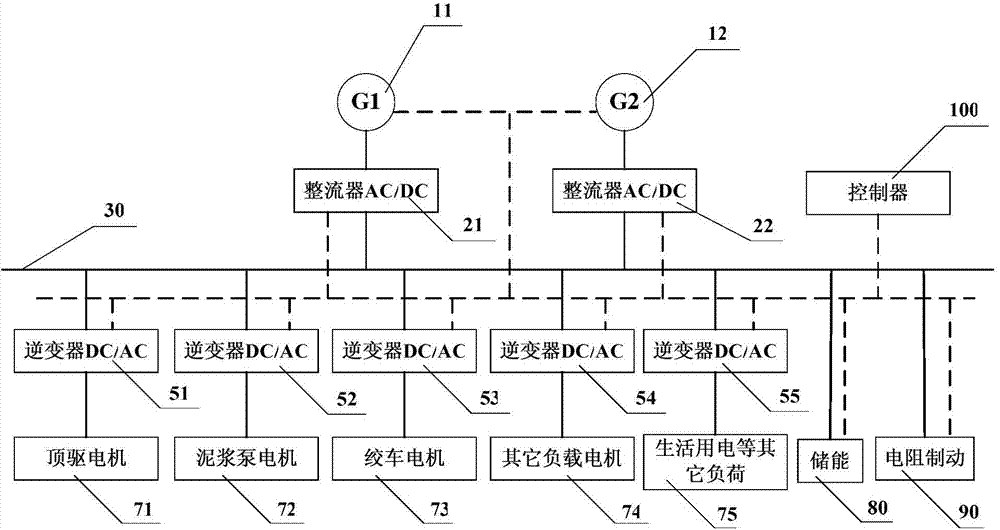

[0037] Such as figure 1 As shown, the DC power supply system includes a DC power supply bus 30, a first generator 11, a second generator 12, a first rectifier 21, a second rectifier 22, a first inverter 51, and a second inverter 52 , third inverter 53, fourth inverter 54, fifth inverter 55, top drive motor 71, mud pump motor 72, winch motor 73, other load motors 74, domestic electric load 75, energy storage system 80. Resistance braking unit 90, and a controller 100 coupled with generators 11, 12, rectifiers 21, 22, inverters 51, 52, 53, 54, 55, energy storage system 80, and resistance braking unit 90 .

[0038] The output end of the first generator 11 is connected to the AC side of the first rectifier 21; the output end of the second generator 12 is connected to the AC side of the second rectifier 22; the AC side of the first inverter 51 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com