System for purifying chlorosilane through non-relevant tower differential pressure thermal coupling

A chlorosilane and thermal coupling technology, applied in the directions of halogenated silanes, halogenated silicon compounds, fractionation, etc., can solve the problems of reducing energy consumption, lack of differential pressure thermal coupling conditions, and inability to ensure differential pressure thermal coupling, etc., to achieve energy consumption. Low, extended range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

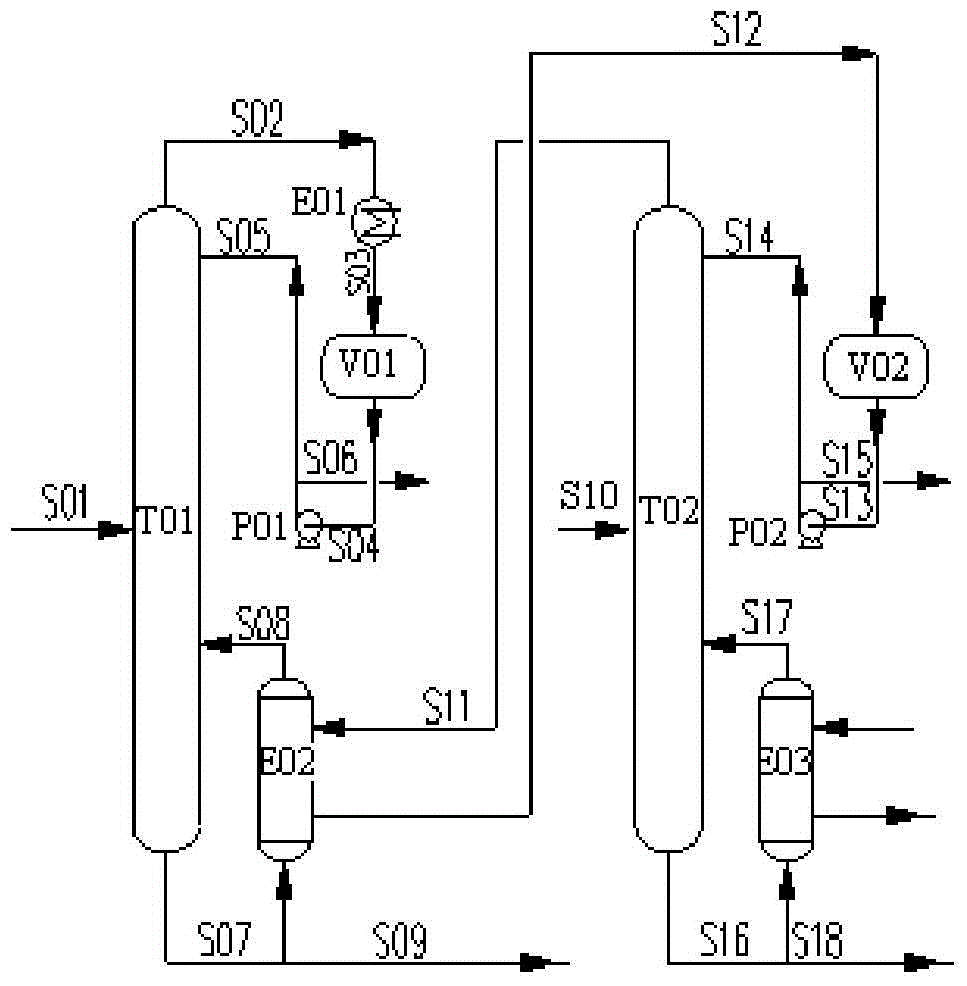

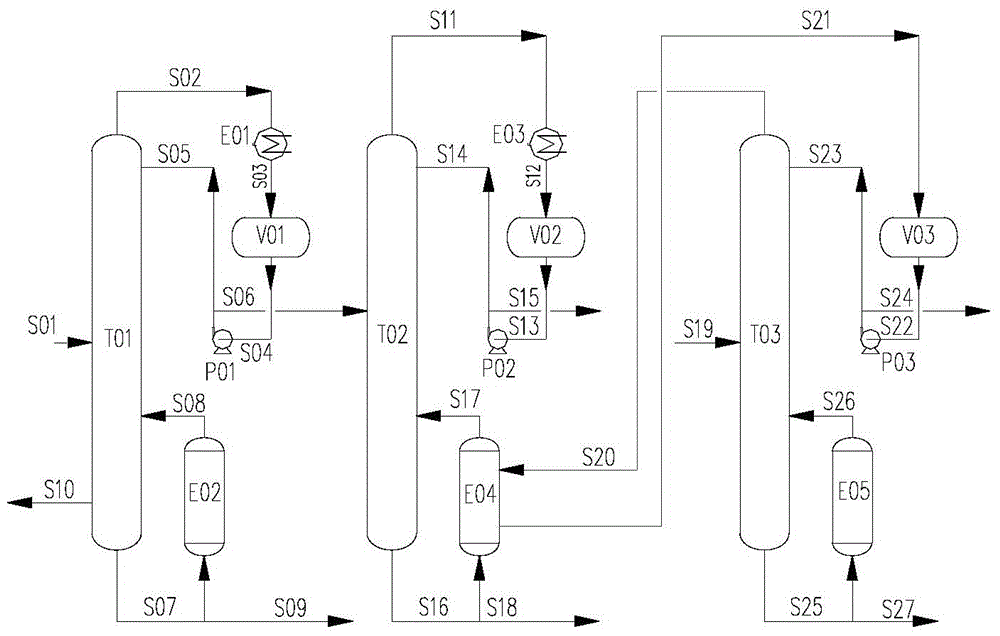

[0062] The polysilicon system includes a crude distillation column group for processing cold hydrogenation materials and a recovery tower for processing high and low boiling points of each group of columns. The feed volume of the crude distillation column group is 60m 3 / h, the feed composition is trichlorosilane 20wt%, dichlorodihydrosilane 2wt%, silicon tetrachloride 78wt%, the material contains some silicon powder, metal compounds and other particulate impurities, and contains a large amount of hydrogen, hydrogen chloride Wait for non-condensable gas; the feed volume of the recovery tower is 35m 3 / h, the feed composition is trichlorosilane 93wt%, dichlorodihydrosilane 3wt%, and silicon tetrachloride 4wt%.

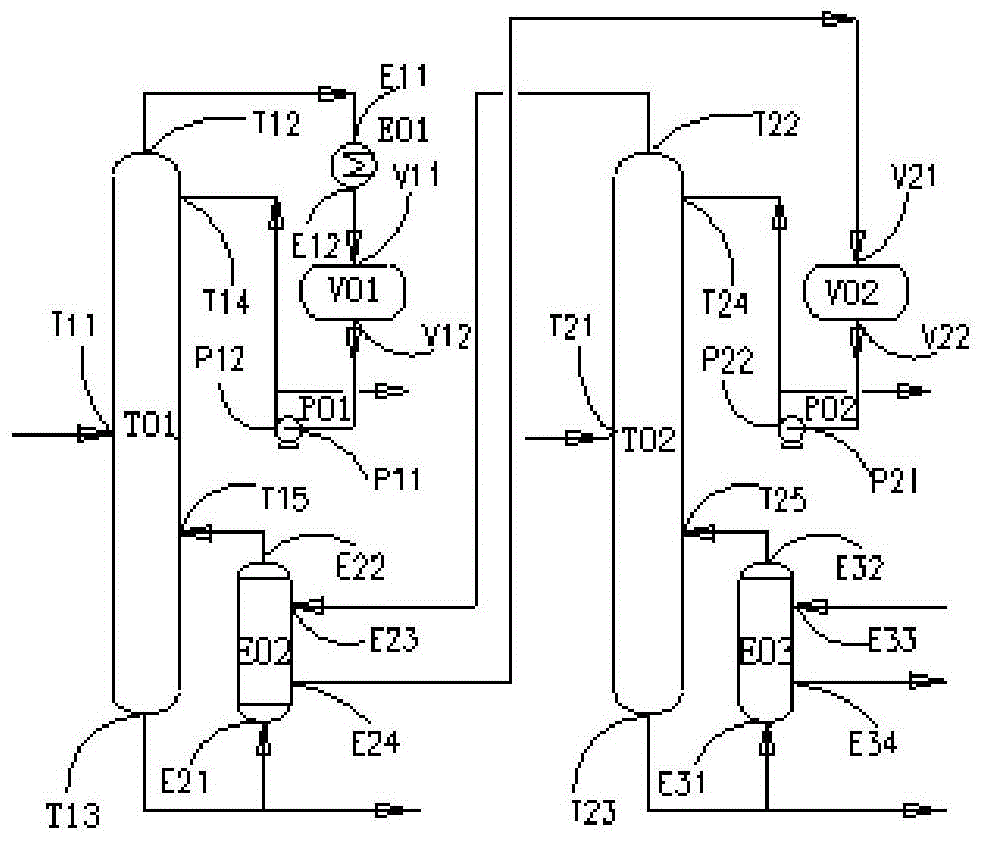

[0063] According to the conventional series differential pressure thermal coupling, the crude distillation column group does not have the conditions for series differential pressure thermal coupling. The crude distillation tower group does not have a series differenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com