Farm excrement comprehensive utilization system and method

A technology for breeding farms and manure, which is applied in the fields of environmental protection and waste resource utilization, can solve the problems of difficulty in realizing manure resource utilization and pollution, and achieve the effect of promoting sustainable development and improving the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

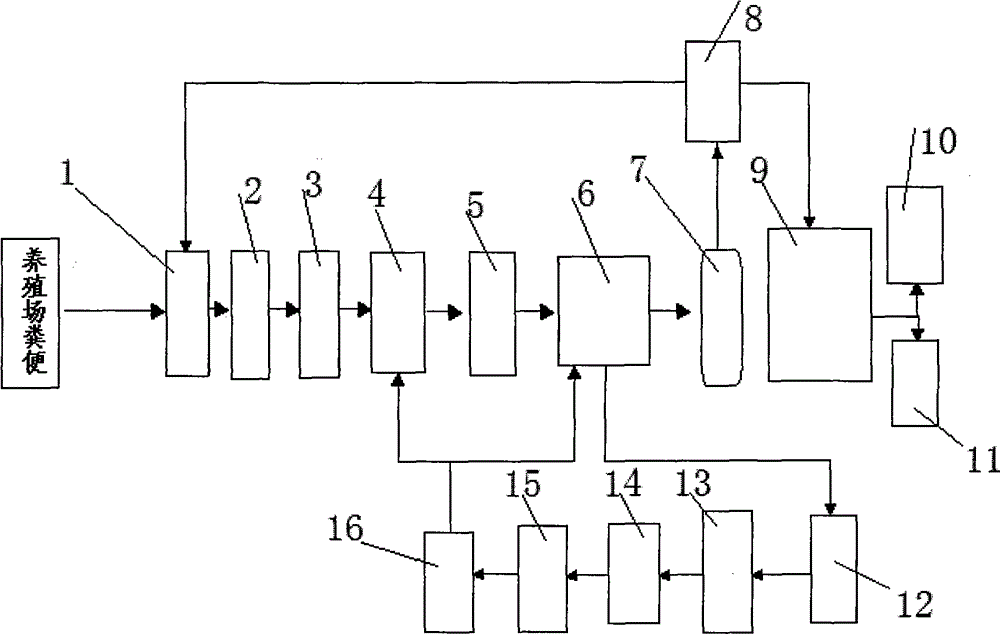

[0024] A kind of comprehensive utilization system of farm manure, such as figure 1 As shown, the septic tank 1 is connected to the pretreatment tank 2, the cutting pump 3 and the metering heating tank 4 in sequence, the metering heating tank 4 is connected to the CSTR reactor 6 through the feed pump 5, and the CSTR reactor 6 is connected to the discharge tank 7 , the discharge tank 7 is connected with the reflux pump 8, the reflux pump 8 is connected with the septic tank 1 and the dehydrator 9 respectively, the dehydrator 9 is connected with the biogas slurry storage 10 and the biogas residue storage pond 11 respectively, and the CSTR reactor 6 is also connected with The water sealer 12 is connected, and the water sealer 12 is sequentially connected with the steam-water separator 13, the desulfurization tower 14, the wet gas storage tank 15 and the generator 16, and the generator 16 is respectively connected with the CSTR reactor 6 and the metering heating pool 4 through the he...

Embodiment 2

[0036] A kind of comprehensive utilization system of farm manure, such as figure 1 As shown, the septic tank 1 is connected to the pretreatment tank 2, the cutting pump 3 and the metering heating tank 4 in sequence, the metering heating tank 4 is connected to the CSTR reactor 6 through the feed pump 5, and the CSTR reactor 6 is connected to the discharge tank 7 , the discharge tank 7 is connected with the reflux pump 8, the reflux pump 8 is connected with the septic tank 1 and the dehydrator 9 respectively, the dehydrator 9 is connected with the biogas slurry storage 10 and the biogas residue storage pond 11 respectively, and the CSTR reactor 6 is also connected with The water sealer 12 is connected, and the water sealer 12 is sequentially connected with the steam-water separator 13, the desulfurization tower 14, the wet gas storage tank 15 and the generator 16, and the generator 16 is respectively connected with the CSTR reactor 6 and the metering heating pool 4 through the he...

Embodiment 3

[0048] A kind of comprehensive utilization system of farm manure, such as figure 1 As shown, the septic tank 1 is connected to the pretreatment tank 2, the cutting pump 3 and the metering heating tank 4 in sequence, the metering heating tank 4 is connected to the CSTR reactor 6 through the feed pump 5, and the CSTR reactor 6 is connected to the discharge tank 7 , the discharge tank 7 is connected with the reflux pump 8, the reflux pump 8 is connected with the septic tank 1 and the dehydrator 9 respectively, the dehydrator 9 is connected with the biogas slurry storage 10 and the biogas residue storage pond 11 respectively, and the CSTR reactor 6 is also connected with The water sealer 12 is connected, and the water sealer 12 is sequentially connected with the steam-water separator 13, the desulfurization tower 14, the wet gas storage tank 15 and the generator 16, and the generator 16 is respectively connected with the CSTR reactor 6 and the metering heating pool 4 through the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com