Preparation and usage methods of ceramic glaze nano-pore aqueous solution additive

A nanoporous, ceramic glaze technology, applied in the use of additives, the preparation of ceramic glaze additives using nanoporous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of additives: pass water vapor above 150°C through nanoporous material particles with a pore size of less than 100 nanometers, and the aqueous solution obtained after condensation is the nanoporous aqueous solution additive, and the nanoporous material particles include SiO 2 、TiO 2 、Al 2 o 3 , Fe 2 o 3 And zeolite, the weight ratio is: 0.65:0.10:0.05:0.10:0.10.

[0025] (2) Preparation of glaze: add 20% by weight of nanoporous aqueous solution additive to every liter of ceramic glaze, and mix and stir evenly.

[0026] (3) Firing process: apply the glaze added with the nano-porous aqueous solution additive to the inner layer of the ceramic embryo container, and fire it in a kiln at 1230°C to 1380°C to form a ceramic product.

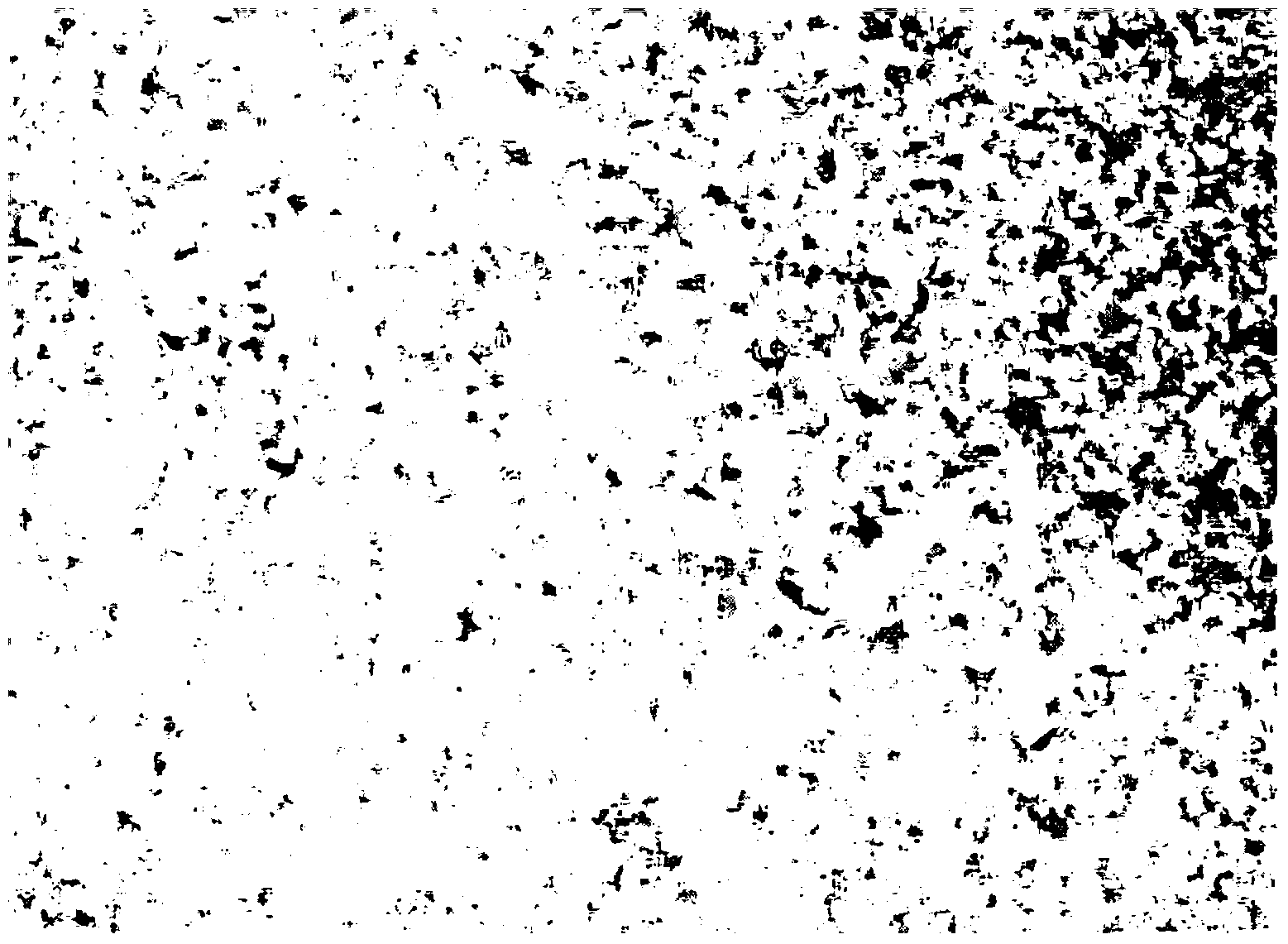

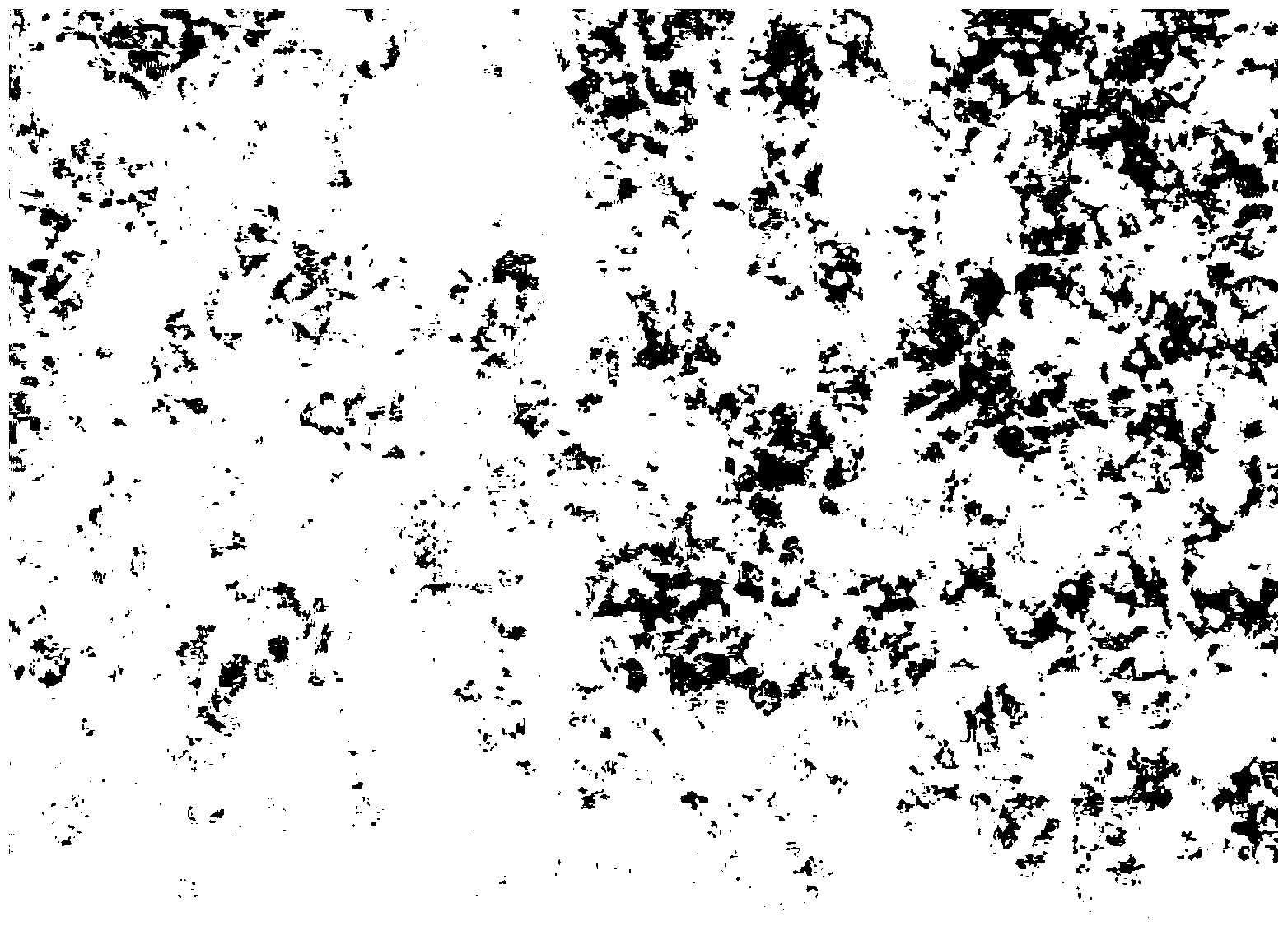

[0027] refer to figure 1 and figure 2 , it can be seen that the ceramic crystallization distribution in Example 1 is a very regular high density, while the ceramic crystallization distribution provided by the prior art is i...

Embodiment 2

[0029] (1) Preparation of additives: pass water vapor above 150°C through nanoporous material particles with a pore size of less than 100 nanometers, and the aqueous solution obtained after condensation is the nanoporous aqueous solution additive, and the nanoporous material particles include SiO 2 、TiO 2 、Al 2 o 3 , Fe 2 o 3 And zeolite, the weight ratio is: 0.65:0.12:0.04:0.09:0.12.

[0030] (2) Preparation of glaze: adding 45% by weight of nanoporous aqueous solution additive to each liter of ceramic glaze, and mixing and stirring evenly.

[0031] (3) Preparation and firing process of the ceramic green body: Mix the steamed nanoporous material particle residue and ordinary ceramic green body evenly to make a ceramic green body, the mixing ratio is 1:0.1, and add additives to the ceramic green body. The ceramic glaze with nano-porous aqueous solution additives is fired into ceramics in a kiln at 880°C to 1380°C.

Embodiment 3

[0033] (1) Preparation of additives: pass water vapor above 150°C through nanoporous material particles with a pore size of less than 100 nanometers, and the aqueous solution obtained after condensation is the nanoporous aqueous solution additive, and the nanoporous material particles include SiO 2 、TiO 2 、Al 2 o 3 , Fe 2 o 3 And zeolite, the weight ratio is: 0.65:0.10:0.05:0.10:0.10.

[0034] (2) Preparation of glaze: add 50% by weight of nanoporous aqueous solution additive to every liter of ceramic glaze, and mix and stir evenly.

[0035] (3) The preparation and firing process of the ceramic body: it is prepared by mixing the nanoporous material particle residue after steaming, calcium carbonate, and ordinary ceramic blank, and the mixing weight ratio is 0.15:0.05:1, and the calcium carbonate is shell powder.

[0036] The ceramic glaze added with nano-porous aqueous solution additive is applied on the ceramic body, and the ceramic product is fired in a kiln at 1230°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com