Ultraviolet resistant polyethylene glycol terephthalate PET film

An anti-ultraviolet and ultraviolet technology, which is applied in the field of anti-ultraviolet PET film, can solve the problems of affecting visual effects, film transmittance and haze, etc., and achieve the effect of prolonging timeliness and not easy to migrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

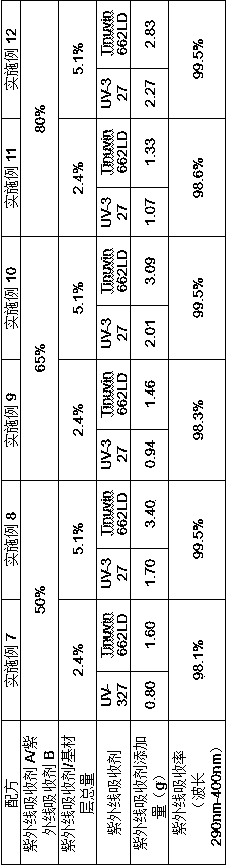

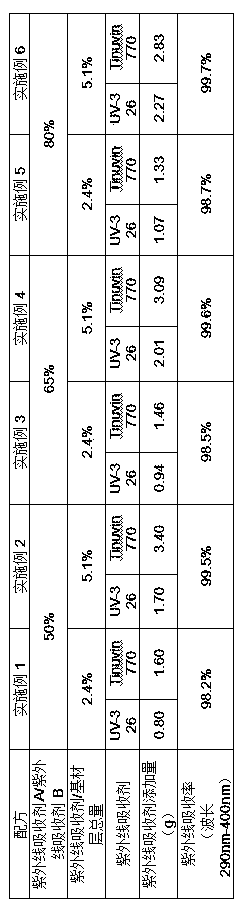

Embodiment 1

[0027] An anti-ultraviolet PET film in this embodiment, the PET masterbatch of the PET film is mixed with ultraviolet absorber UV-326 (Nanjing Milan Chemical Co., Ltd.) and Tinuvin 770 (Yixing Angel Synthetic Chemical Co., Ltd.).

[0028] The preparation method of above-mentioned anti-ultraviolet PET film comprises the steps:

[0029] Step 1: Mix 97.6g PET masterbatch, 0.8g UV-326 (Nanjing Milan Chemical Co., Ltd.) and 1.6g Tinuvin 770 (Yixing Angel Synthetic Chemical Co., Ltd.), and dry to control the moisture content below 50ppm to obtain raw material mixture;

[0030] Step 2: Put the raw material mixture obtained in Step 1 into the reaction kettle, heat up to 270°C to melt the mixture, filter it, extrude it, and rapidly cool it through a cold drum; then preheat it for transverse stretching and longitudinal stretching, the preheating temperature At 200°C, it is finally formed into a transparent PET film.

Embodiment 2

[0032] An anti-ultraviolet PET film in this embodiment, the PET masterbatch of the PET film is mixed with ultraviolet absorber UV-326 (Nanjing Milan Chemical Co., Ltd.) and Tinuvin 770 (Yixing Angel Synthetic Chemical Co., Ltd.).

[0033] The preparation method of above-mentioned anti-ultraviolet PET film comprises the steps:

[0034] Step 1: Mix 94.9g of PET masterbatch, 1.7g of UV-326 (Nanjing Milan Chemical Co., Ltd.) and 3.4g of Tinuvin 770 (Yixing Angel Synthetic Chemical Co., Ltd.), and dry to control the moisture content below 50ppm to obtain raw material mixture;

[0035] Step 2: Put the raw material mixture obtained in Step 1 into the reaction kettle, heat up to 270°C to melt the mixture, filter it, extrude it, and rapidly cool it through a cold drum; then preheat it for transverse stretching and longitudinal stretching, the preheating temperature At 200°C, it is finally formed into a transparent PET film.

Embodiment 3

[0037] An anti-ultraviolet PET film in this embodiment, the PET masterbatch of the PET film is mixed with ultraviolet absorber UV-326 (Nanjing Milan Chemical Co., Ltd.) and Tinuvin 770 (Yixing Angel Synthetic Chemical Co., Ltd.).

[0038] The preparation method of above-mentioned anti-ultraviolet PET film comprises the steps:

[0039] Step 1: Mix 97.6g of PET masterbatch, 0.94g of UV-326 (Nanjing Milan Chemical Co., Ltd.) and 1.46g of Tinuvin 770 (Yixing Angel Synthetic Chemical Co., Ltd.), and dry to control the moisture content below 50ppm to obtain raw material mixture;

[0040] Step 2: Put the raw material mixture obtained in Step 1 into the reaction kettle, heat up to 270°C to melt the mixture, filter it, extrude it, and rapidly cool it through a cold drum; then preheat it for transverse stretching and longitudinal stretching, the preheating temperature At 200°C, it is finally formed into a transparent PET film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com