SCC corrosion-resistant pipeline steel and its manufacturing process

A manufacturing process and pipeline steel technology, applied in the field of SCC corrosion-resistant pipeline steel and its preparation, can solve the problems of high precious metal content, cold cracks in the welding area, and reduce ductility, etc., to achieve low precious metal content and high tensile strength and yield strength, the effect of ensuring hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with specific embodiments.

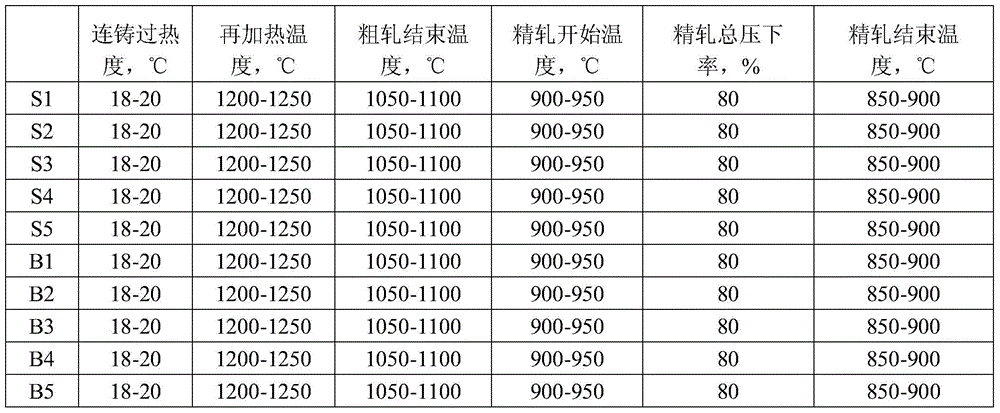

[0015] The pipeline steel described in this embodiment does not add precious metal elements such as Mo and V, and the amount of Ni and Cr is relatively low, which is controlled within an economically appropriate range. The design concept of low carbon and high manganese is adopted, supplemented by copper, Titanium and other elements produce high-strength steel with excellent comprehensive properties; and by adding appropriate amounts of Mg, W and controlling the content of Ni and Cr, it not only ensures the weathering and corrosion resistance of the steel, but also has excellent resistance to SCC corrosion and HIC Corrosion performance. The pipeline steel described in this embodiment adopts Ti and Al microalloying technology to control the final cooling temperature at 480-550°C, which helps to ensure that the steel has fine grains and uniform structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com