Chlorination furnace slag washing treatment method and use of treatment liquid

A technology for water washing treatment and liquid treatment, applied in the field of smelting, can solve the problems of water failing to meet the national discharge standard and can not be directly discharged, and achieve the effect of solving the problems of treatment and resource utilization and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

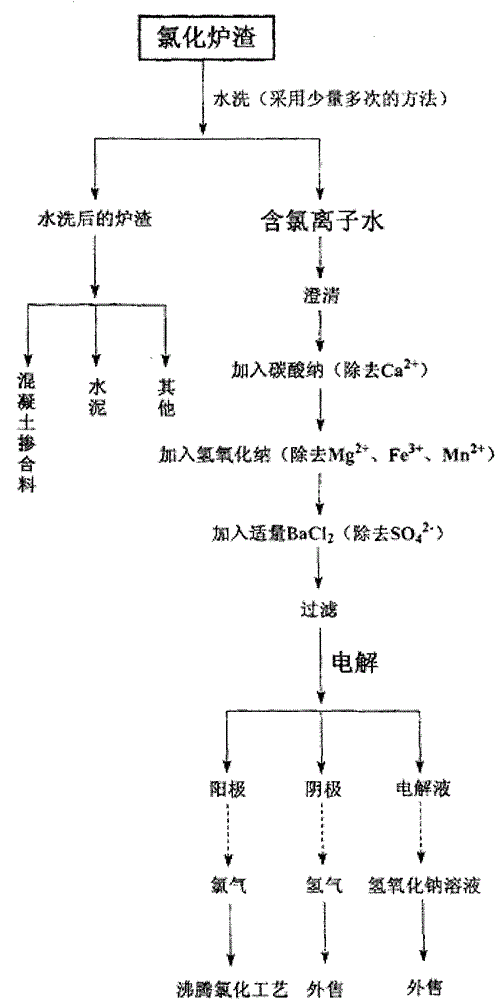

[0016] Process route of the present invention such as figure 1 As shown, it mainly includes three steps: 1. washing of chlorinated slag; 2. purification treatment of chloride-ion-containing water; 3. electrolysis of chloride-ion-containing water, as follows:

[0017] ①Water washing of chlorinated slag:

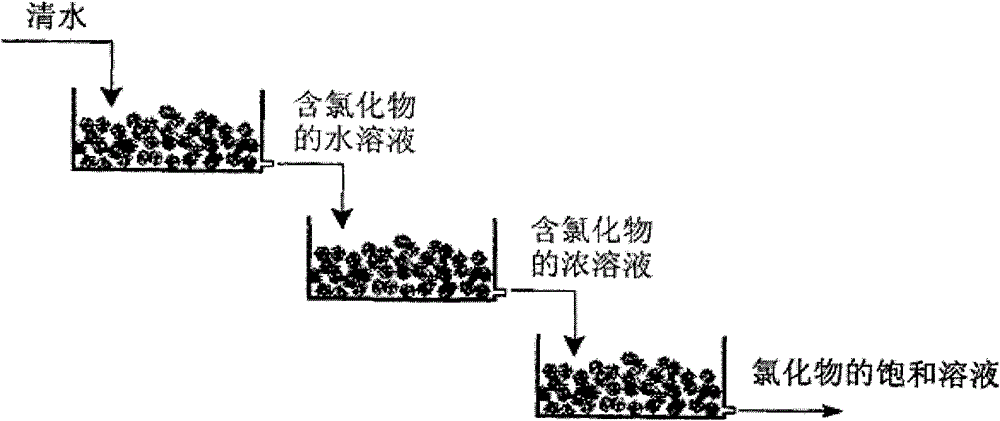

[0018] Such as figure 2 As shown, the washing method of chlorinated slag adopts a small amount of multiple times, and the number of times of washing is more than three times, that is, soak the chlorinated slag with a small amount of clear water (required to submerge the slag for 10-20 cm) for more than 1-2 hours (except the first In addition to one washing cycle, the slag here is cleaned for the last time, the height of the tank where the chlorinated slag is placed exceeds 0.3m, and the amount of chlorinated slag added reaches two-thirds of the tank volume), the washing water is released, and the aqueous solution flows into the In the next tank containing chlorinated slag (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com