Vintage knitted fabric with surface whitening effect, finished garment and processing method of two

A technology for knitted fabrics and processing methods, applied in dyeing, textile and papermaking, fiber processing, etc., can solve the problems of long production process, environmental pollution, water and energy consumption, etc., and achieve high production efficiency, reduce costs, and shorten the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

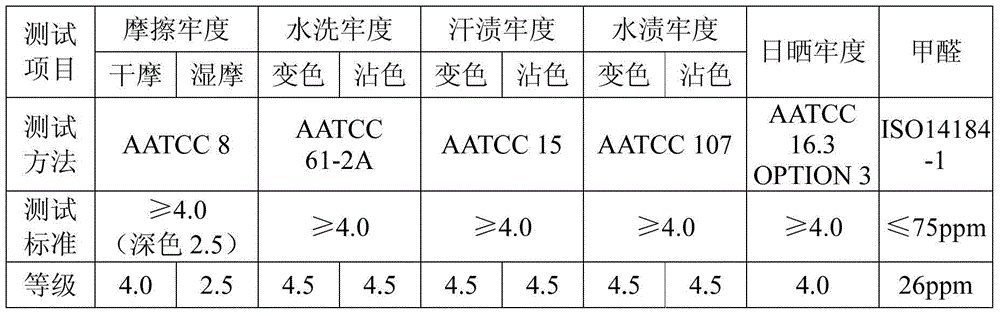

Embodiment 1

[0047] This embodiment provides a processing method for finished garments of imitation knitted fabrics with a white surface effect, which is used to process a black distressed knitted round neck sweater with a white surface effect. The fabric used is 40S / 2100% Cotton4-mode double piqué Knitted fabric, the weight is 210g / m 2 , the processing method includes the following steps:

[0048] 1. Pre-treatment of knitted fabrics:

[0049] According to the conventional pretreatment process of the textile printing and dyeing industry, the knitted fabrics are subjected to scouring, bleaching, cellulase polishing and other treatments. The scouring requirements are sufficient, and the knitted fabrics before coating with paint must have good hydrophilicity.

[0050] 2. One-sided slurry coating of paint:

[0051] Preparation of coloring slurry: the slurry contains 15g / L paint black FBRN (produced by Foshan Kexun Ink Coating Co., Ltd.), 30g / L thickener SL681 (produced by Guangzhou Xinyi Che...

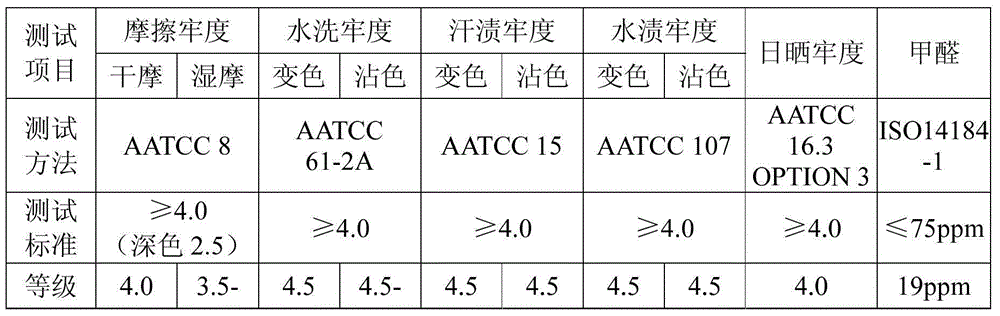

Embodiment 2

[0066] This example provides a method for processing a red distressed knitted T-shirt with a white surface effect. The fabric used is 30S / 1100% Cotton4-mode single-piqué knitting. Cloth, the weight is 200g / m 2 .

[0067] The processing method comprises the following steps:

[0068] 1. Pre-treatment of knitted fabrics:

[0069] According to the conventional pretreatment process of the textile printing and dyeing industry, the knitted fabrics are subjected to scouring, bleaching, cellulase polishing and other treatments. The scouring requirements are sufficient, and the knitted fabrics before coating with paint must have good hydrophilicity.

[0070] 2. Paint single-sided foam coloring:

[0071] Preparation of dye solution: dye solution contains 10g / L of paint red FFG (produced by Foshan Kexun Ink Coating Co., Ltd.), 10g / L of foaming agent RR (produced by Bussett (Ningbo) Chemical Co., Ltd.), 5g / L L thickener SL681 (produced by Guangzhou Xinyi Chemical Co., Ltd.), 50g / L bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com