Preparation method of an enzyme sensor and method for measuring hydrogen peroxide

A technology of enzyme sensor and hydrogen peroxide, which is applied in the field of enzyme sensor and electroanalytical chemical detection, can solve the problems of complicated and cumbersome hydrotalcite-modified electrode conductivity, etc., and achieve large specific surface area, good biocompatibility, and good conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

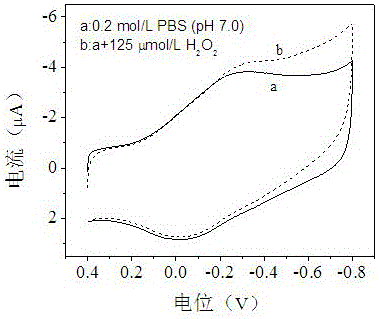

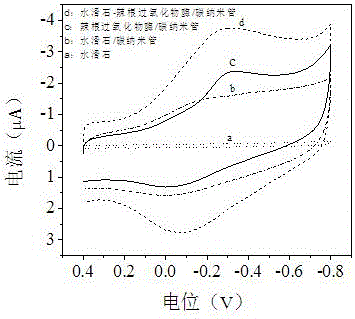

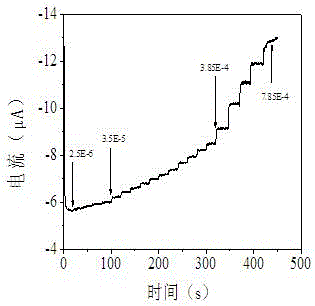

[0021] The enzyme sensor was prepared with hydrotalcite as the carrier.

[0022] (1) Use a micro-syringe to take 3 μl of dispersed 0.5 mg / mL carbon nanotube suspension and evenly drop it on the surface of a clean glassy carbon electrode, let it dry naturally at room temperature, and rinse it with deionized water to obtain carbon nanotubes Modified electrodes.

[0023] (2) First prepare the electrodeposition solution containing 15 mmol / L cobalt nitrate, 5 mmol / L aluminum nitrate, 0.1 mol / L potassium nitrate and 0.3 mg / mL horseradish peroxidase, and then place the carbon nanotube modified electrode on the The constant potential deposition was carried out in the electrodeposition solution at -0.6 V for 80 s. After the deposition, it was rinsed with deionized water to obtain a hydrotalcite-horseradish peroxidase / carbon nanotube modified electrode. The oxidase-modified electrode is the enzyme sensor for the determination of hydrogen peroxide.

Embodiment 2

[0025] The enzyme sensor was prepared with hydrotalcite as the carrier.

[0026] (1) Use a micro-syringe to take 5 μl of dispersed 0.5 mg / mL carbon nanotube suspension and evenly drop it on the surface of a clean glassy carbon electrode, let it dry naturally at room temperature, and rinse it with deionized water to obtain carbon nanotubes Modified electrodes.

[0027] (2) First prepare the electrodeposition solution containing 21 mmol / L cobalt nitrate, 7 mmol / L aluminum nitrate, 0.2 mol / L potassium nitrate and 0.5 mg / mL horseradish peroxidase, and then place the carbon nanotube modified electrode on The constant potential deposition was carried out in the electrodeposition solution at -0.8 V for 70 s. After the deposition was completed, it was rinsed with deionized water to obtain a hydrotalcite-horseradish peroxidase / carbon nanotube modified electrode. The oxidase-modified electrode is the enzyme sensor for the determination of hydrogen peroxide.

Embodiment 3

[0029] The enzyme sensor was prepared with hydrotalcite as the carrier.

[0030] 1) Use a micro-syringe to take 5 μl of dispersed 1.0 mg / mL carbon nanotube suspension and evenly drop it on the surface of a clean glassy carbon electrode, let it dry naturally at room temperature, and rinse it with deionized water to obtain carbon nanotube modification electrode.

[0031] (2) First prepare the electrodeposition solution containing 22.5 mmol / L cobalt nitrate, 7.5 mmol / L aluminum nitrate, 0.3 mol / L potassium nitrate and 1.0 mg / mL horseradish peroxidase, and then place the carbon nanotube modified electrode on the The constant potential deposition was carried out in the electrodeposition solution at -0.9 V for 30 s. After the deposition was completed, it was rinsed with deionized water to obtain a hydrotalcite-horseradish peroxidase / carbon nanotube modified electrode. The oxidase-modified electrode is the enzyme sensor for the determination of hydrogen peroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com