Preparation method of high-solubility low-phytic-acid soybean protein isolate

A technology of soybean protein isolate and high solubility, which is applied in the field of preparation of soybean protein isolate and low-phytic acid soybean protein isolate, can solve the problems of decreased separation effect, easy contamination of resin, decreased protein solubility and functional properties, etc., and achieves a simple production process. Ease of operation, industrial production, easy and fast enzymatic hydrolysis regulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

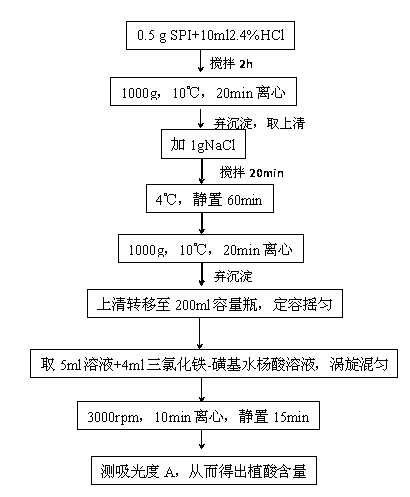

Image

Examples

Embodiment 1

[0034] Take the soybean meal to be processed, crush and sieve; the crushing condition is 35000rpm, time 30s, crush 3 times, each interval is 30s, the mesh number of the sieve is 100 mesh; take 100g soybean meal, press 1:10 (w / v) Mix the ratio with deionized water, stir evenly, adjust the pH to 7.0, stabilize the alkali solution under this condition for 1 hour, then centrifuge at 9500rpm for 30 minutes to obtain a protein solution, adjust the enzymolysis conditions and add 25 U / g soybean meal, time 30min, pH 5.0, temperature 40°C, then quickly adjust the pH to 4.5, carry out acid precipitation, centrifuge at 6000rpm, 30min to obtain curd, dissolve the curd and deionized water at a ratio of 1:10 (w / v) Disintegrate and neutralize to obtain SPI.

[0035] Further investigation and analysis of the phytic acid content and protein solubility of SPI showed that although the phytic acid content was reduced to 0.98mg / g, the protein solubility was also reduced to 80.65%.

Embodiment 2

[0037]Take the soybean meal to be processed, crush and sieve; the crushing condition is 30000rpm, time 1min, crush twice, each interval is 30s, the mesh number of the sieve is 80 mesh; take 100g of defatted soybean meal, press 1:10 (w / v ) and deionized water, stir evenly, adjust the pH to 7.0, and stabilize the alkali solution under this condition for 1 hour, then centrifuge at 9500 rpm for 30 minutes to obtain a protein solution, adjust the enzymolysis conditions and add 50 U / g soybean meal, Time 50min; pH 7.0, temperature 25°C, then quickly adjust the pH to 4.5, carry out acid precipitation, centrifuge at 6000rpm, 30min, to obtain curd, dissolve the curd and deionized water at a ratio of 1:10 (w / v) Afterwards, disintegrate and neutralize to obtain SPI.

[0038] Further investigation and analysis of the phytic acid content and protein solubility of SPI showed that the phytic acid content was reduced to 6.57mg / g, but compared with the control group, the content was still a bit...

Embodiment 3

[0040] Take the soybean meal to be processed, crush and sieve; the crushing condition is 30000rpm, time 1min, crush twice, each interval is 30s, the mesh number of the sieve is 80 mesh; take 100g of defatted soybean meal, press 1:10 (w / v ) with deionized water, stir evenly, adjust the pH to 7.0, and stabilize the alkali solution under this condition for 1 hour, then centrifuge at 9500 rpm for 30 minutes to obtain a protein solution, adjust the enzymolysis conditions and add 30 U / g soybean meal, Time 40min; pH 6.5, temperature 55°C, then quickly adjust the pH to 4.5, carry out acid precipitation, centrifuge at 6000rpm, 30min to obtain curd, dissolve the curd and deionized water at a ratio of 1:10 (w / v) Afterwards, disintegrate and neutralize to obtain SPI.

[0041] Further investigation and analysis of the phytic acid content and protein solubility of SPI showed that although the phytic acid content was reduced to 0.85mg / g, the protein solubility was also reduced to 67.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com