Production method of efficient chelating enzyme peptide

A production method and chelation-type technology, which are applied in peptide preparation methods, microorganism-based methods, biochemical equipment and methods, etc., to maintain the health of intestinal flora, reduce poultry anemia, and reduce feeding costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

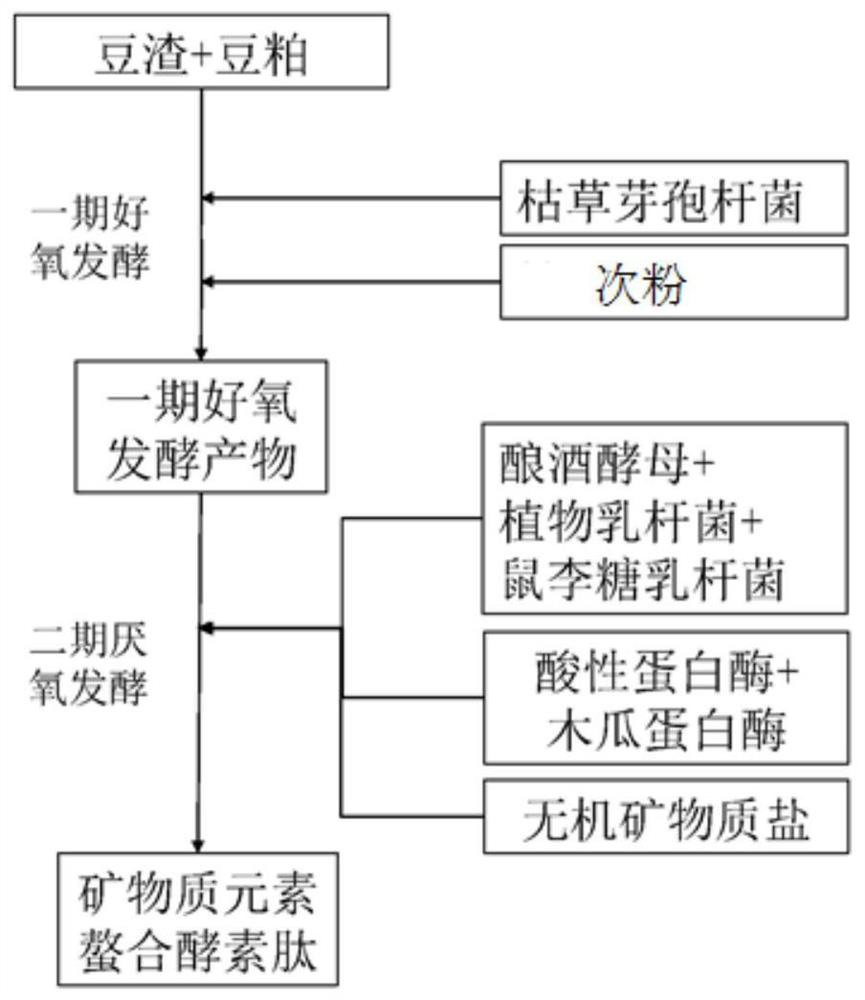

Method used

Image

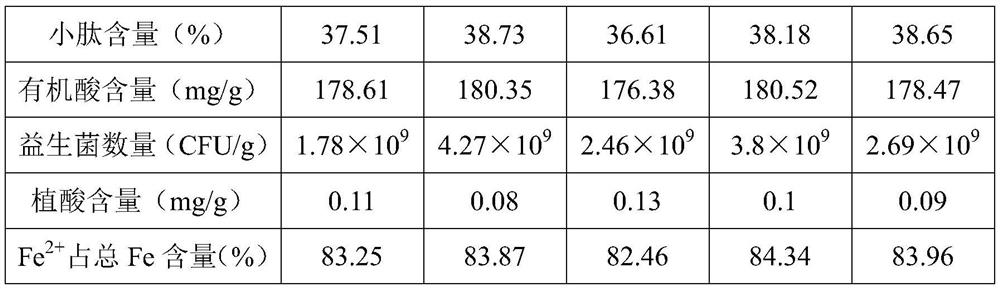

Examples

Embodiment 1

[0032] (1) Activation culture of Bacillus subtilis, Saccharomyces cerevisiae, Lactobacillus plantarum, Lactobacillus rhamnosus and preparation of fermented seed liquid:

[0033] A, the preparation of culture medium:

[0034] Slope and plate medium: yeast extract 5g, peptone 10g, sodium chloride 10g, glucose 10g, agar 20g, distilled water 1000mL, sterilized at 121°C for 30min;

[0035]Seed liquid culture base: 20g soybeans, 20g brown sugar, 1000mL distilled water, make soybean milk, sterilize at 121°C for 30min;

[0036] B. Activation of various strains and preparation of fermented seed liquid:

[0037] Activation of Bacillus subtilis and preparation of fermented seed solution: Inoculate the Bacillus subtilis strains stored at 4°C on the slant medium, and culture at 37°C for 36h. Then streak a single colony on the plate, culture it upside down at 37°C for 36 hours, pick a single colony and inoculate it in a 250mL Erlenmeyer flask containing 50mL of seed liquid medium, and cul...

Embodiment 2

[0044] (1) The activation of Bacillus subtilis, Saccharomyces cerevisiae, Lactobacillus plantarum, Lactobacillus rhamnosus and the preparation method of fermented seed liquid, concrete operation is the same as embodiment 1;

[0045] (2) Preparation of solid fermentation medium: the mass proportion of each component is: soybean dregs 60%, soybean meal 40%;

[0046] (3) The obtained Bacillus subtilis fermentation seed liquid is inoculated in the fermentation medium by the inoculum size of 8% of the quality of the solid fermentation medium, and the secondary powder of 24% of the quality of the solid fermentation medium is added, and water is added to make the water content 55% %, stir evenly, carry out the first stage of aerobic fermentation, the fermentation temperature is 36°C, and the aerobic fermentation is 24h;

[0047] (4) The fermented seed liquid of Saccharomyces cerevisiae, Lactobacillus plantarum and Lactobacillus rhamnosus is inoculated respectively in the fermentation...

Embodiment 3

[0049] (1) The activation of Bacillus subtilis, Saccharomyces cerevisiae, Lactobacillus plantarum, Lactobacillus rhamnosus and the preparation method of fermented seed liquid, concrete operation is the same as embodiment 1;

[0050] (2) Preparation of solid fermentation medium: the mass ratio of each component is: 40% bean dregs, 60% soybean meal;

[0051] (3) The obtained Bacillus subtilis fermented seed liquid is inoculated in the fermented medium by the inoculum amount of 10% of the quality of the solid fermented medium, and the secondary powder of 18% of the quality of the solid fermented medium is added, and water is added to make the water content be 40% %, stir evenly, carry out the first stage of aerobic fermentation, the fermentation temperature is 25°C, and the aerobic fermentation is 48h;

[0052] (4) The fermented seed liquid of Saccharomyces cerevisiae, Lactobacillus plantarum and Lactobacillus rhamnosus is inoculated in the fermentation medium respectively accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com