Tool abrasion monitoring method based on wavelet denoising and Hilbert-Huang transformation

A wavelet denoising and tool wear technology, applied in the field of signal processing, can solve problems such as energy leakage and insufficient self-adaptation, and achieve strong adaptability, high self-adaptability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

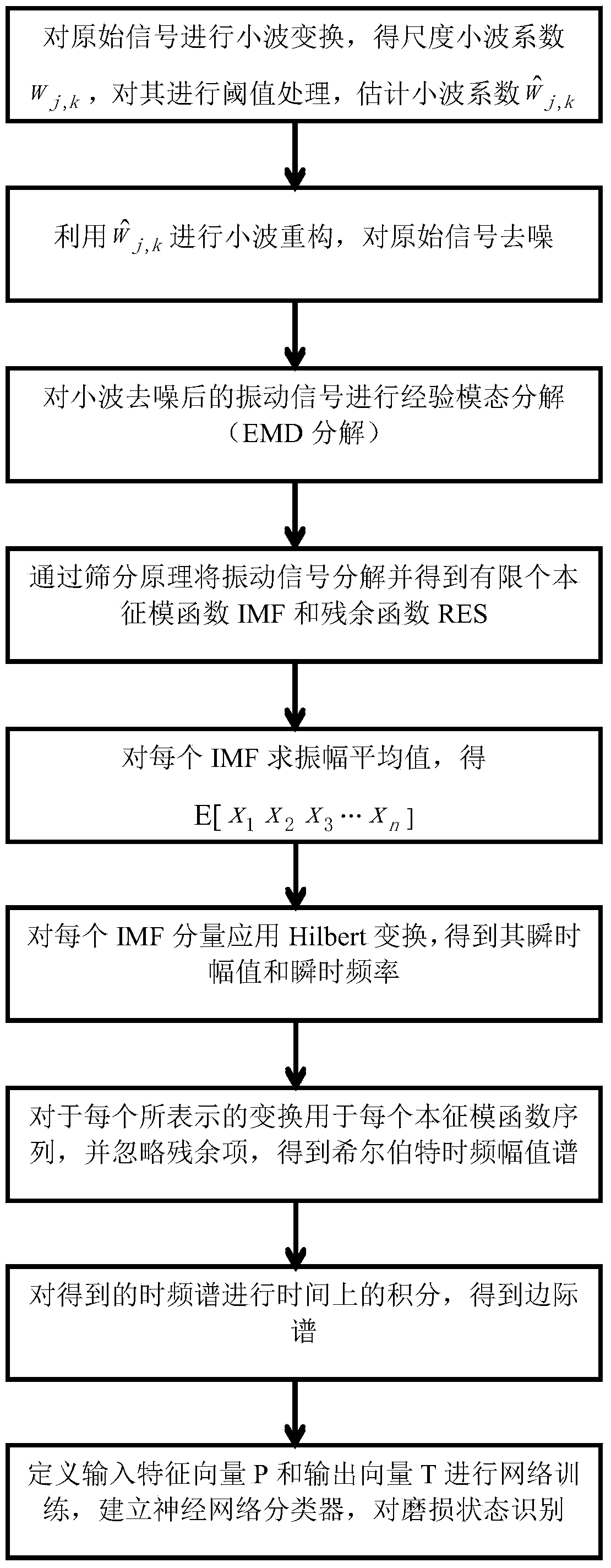

[0039] A tool wear monitoring method based on wavelet denoising and Hilbert-Huang transform in this embodiment adopts the following steps:

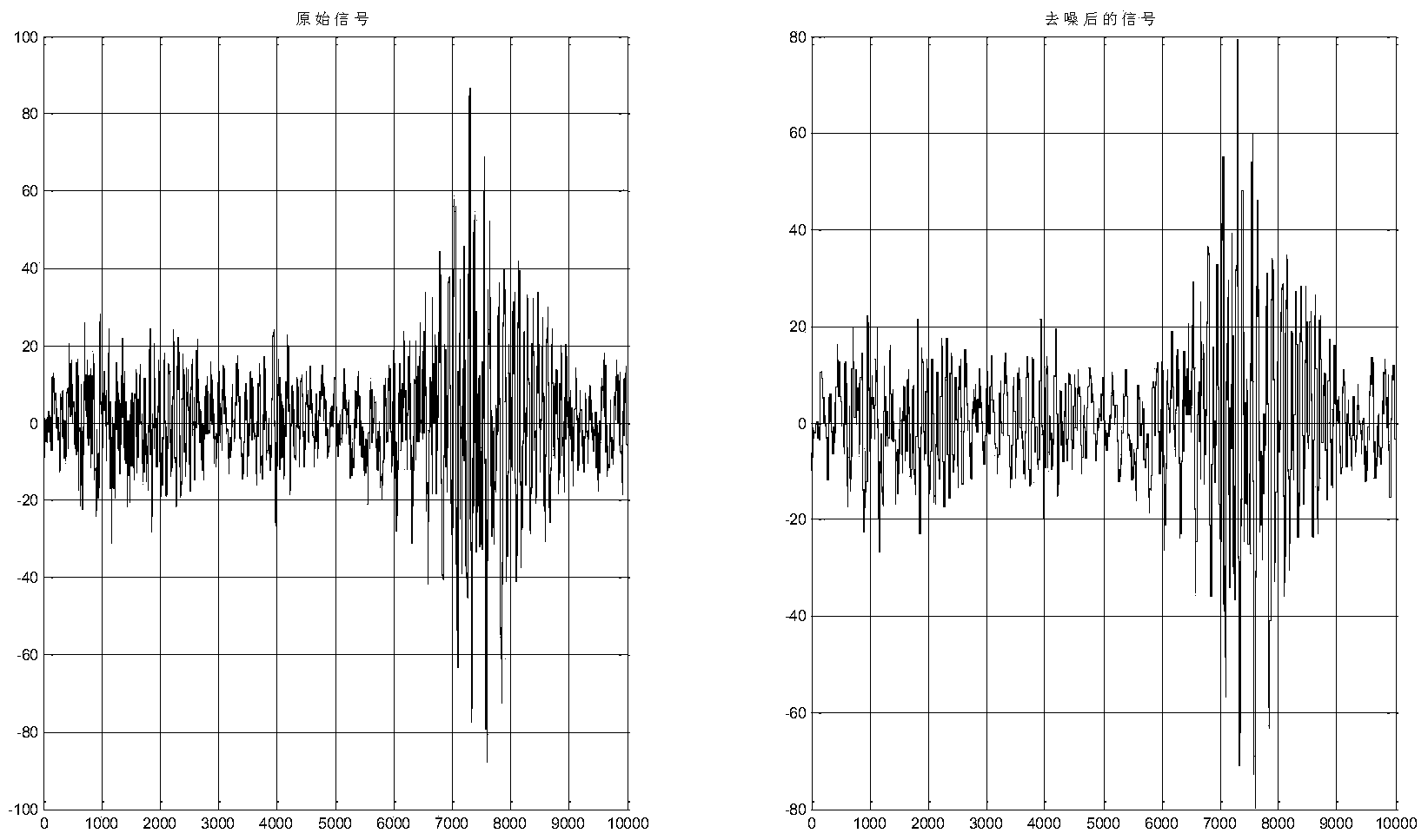

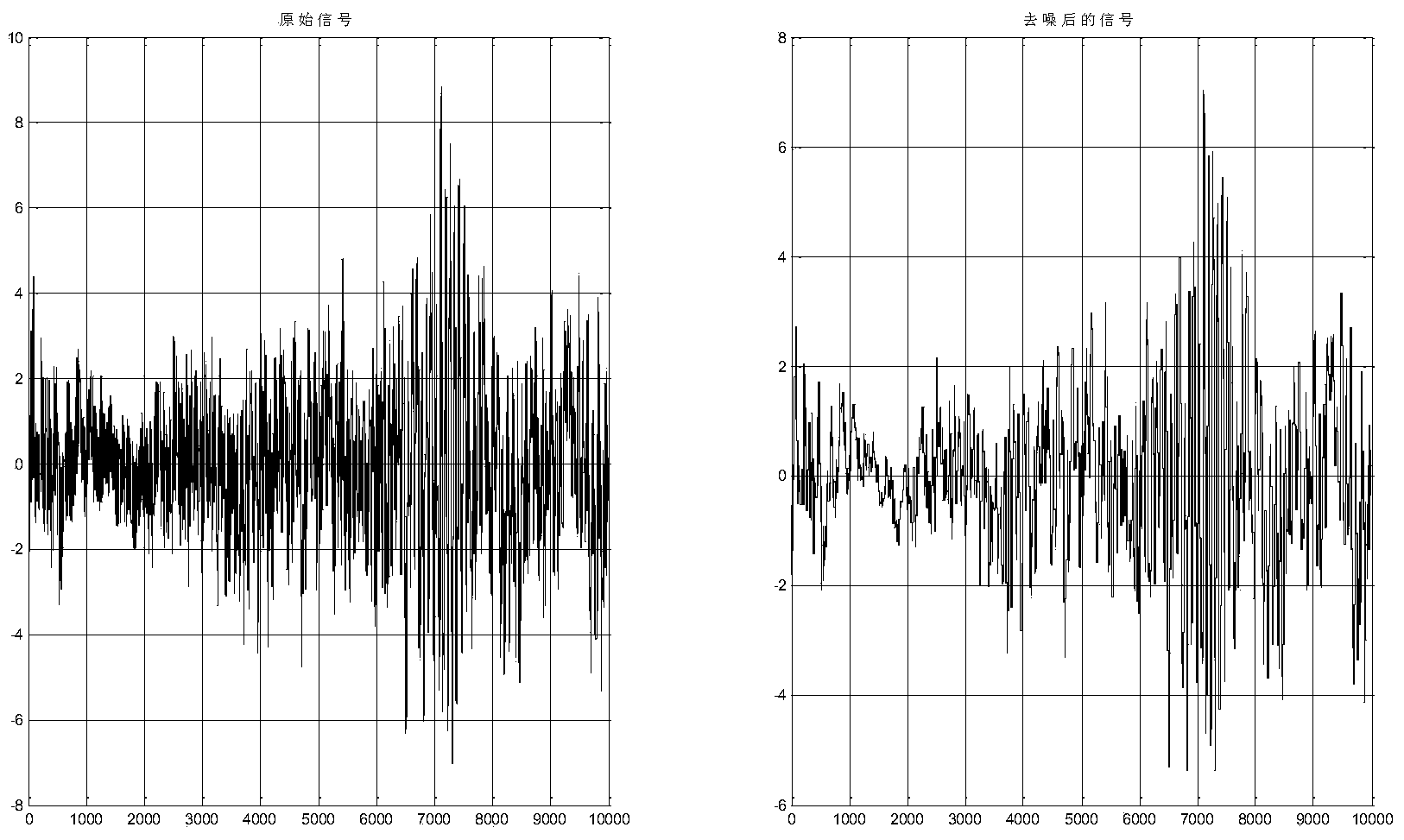

[0040] Step 1: Collect the vibration signals of several groups of tools of the same type in three time periods during operation. The three time periods correspond to the initial wear, normal wear and severe wear of the tool respectively; the sampling time of the three time periods is the same; different groups have the same The cutting parameters during the operation of the type tool are different.

[0041] In this embodiment, using the orthogonal test method, according to the three cutting elements and the designation plan of the tool wear amount, as shown in Table 1 and Table 2, the cutting parameters of the milling machine are respectively set, that is, the spindle speed, the feed rate, the cutting depth, and the vibration sensor is used to control the machine tool. During the operation process, 16 groups of vibration signals were coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com