Method and device for deep oil removal of wastewater containing low-concentration sump oil

A low-concentration, waste water technology, applied in the direction of grease/oily substance/suspton removal device, separation method, mining wastewater treatment, etc., can solve the problem of not meeting the requirements of deep degreasing of waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] On the offshore oil platform of an oil company’s crude oil exploitation, the method and device of the present invention suitable for deep degreasing wastewater containing low-concentration sewage oil are used to degrease the production wastewater after sedimentation, swirling, and air flotation separation , the deoiled sewage reaches the discharge standard and is discharged into the sea.

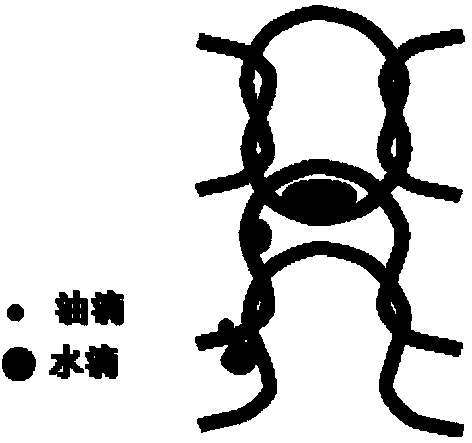

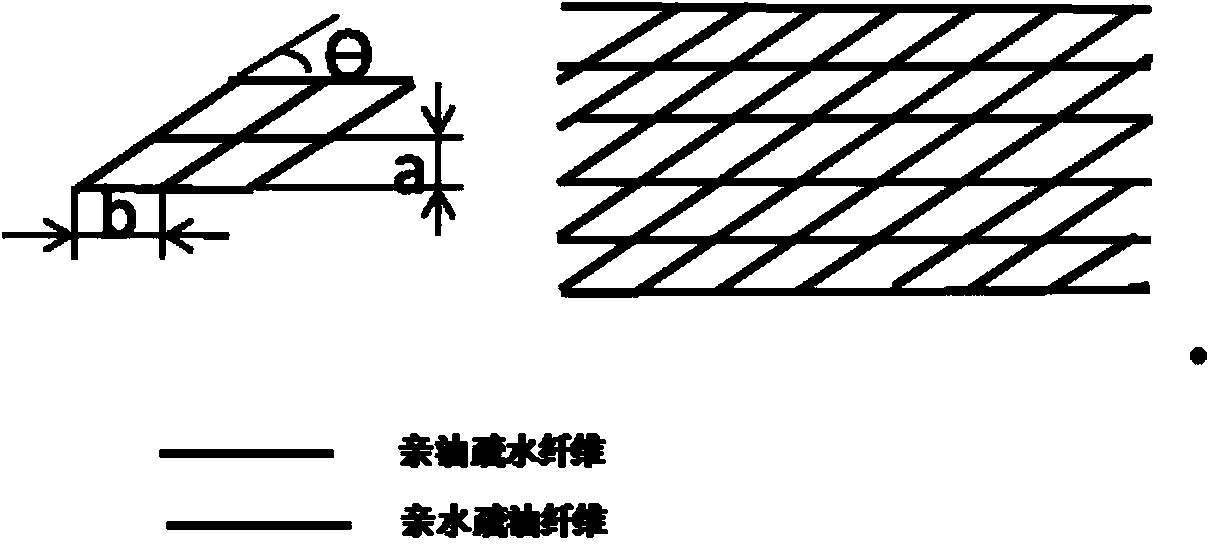

[0041] The schematic diagram of the above-mentioned device is shown in Figure 6 As shown, it includes shell 1, oily wastewater inlet 2, fluid rectifier 3, X-shaped braided layer 4 (fiber coalescing and separation layer), corrugated reinforced separation layer 5, Ω-shaped braided layer 10 (fiber coalescing and replenishing layer), Oil bag 6, oil phase outlet 7 and purified water phase outlet 9. The oily waste water inlet 2 is at one end of the upper part of the housing 1 , the oil bag 6 is at the other end of the upper part of the housing 1 , the oil bag 6 has a liquid level gauge 8 , ...

Embodiment 2

[0051] A petrochemical company's oil refinery sewage treatment workshop sewage adopts a kind of equipment suitable for deep degreasing of waste water containing low concentration sewage oil according to the present invention, and degreases the waste water after sedimentation pretreatment, and achieves biochemical treatment after degreasing Require.

[0052] Other conditions are the same as embodiment 1, and the specific operation process and effect of different parts are described as follows:

[0053] The operating conditions of the wastewater after gravity sedimentation pretreatment in the sewage treatment workshop: operating pressure: 0.2MPa; operating temperature 40-60°C, sewage oil content 80-100mg / L.

[0054] Requirement index: The oil content in the sewage after degreasing is not more than 25mg / L.

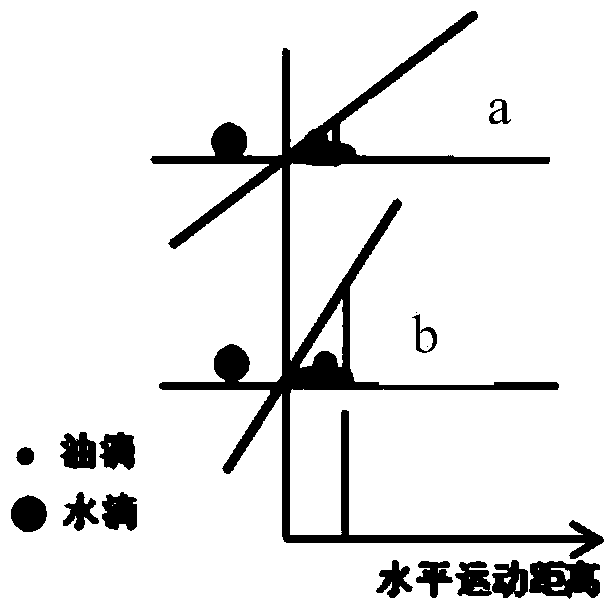

[0055] Solution selection: In this solution, the sewage has undergone simple sedimentation and separation at the initial stage, so most of the oil droplets in the wastewater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com