Architectural ornament coating, and preparation method and application thereof

A technology for architectural decoration and coatings, applied in the field of architectural decorative coatings and their preparation, can solve problems such as short service life and insufficient wall decoration strength, and achieve the effect of adhesion wall, not easy to efflorescence, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

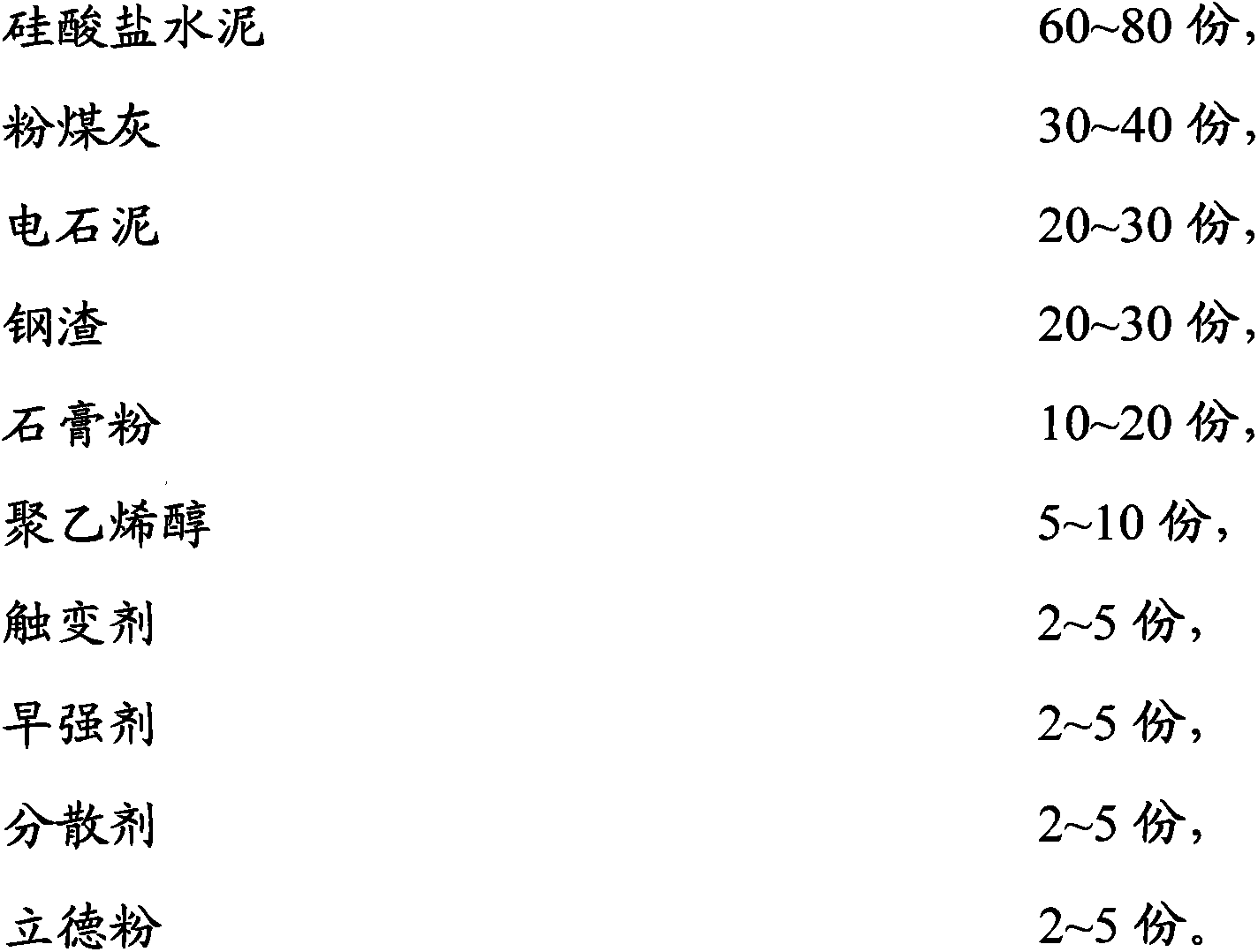

Method used

Image

Examples

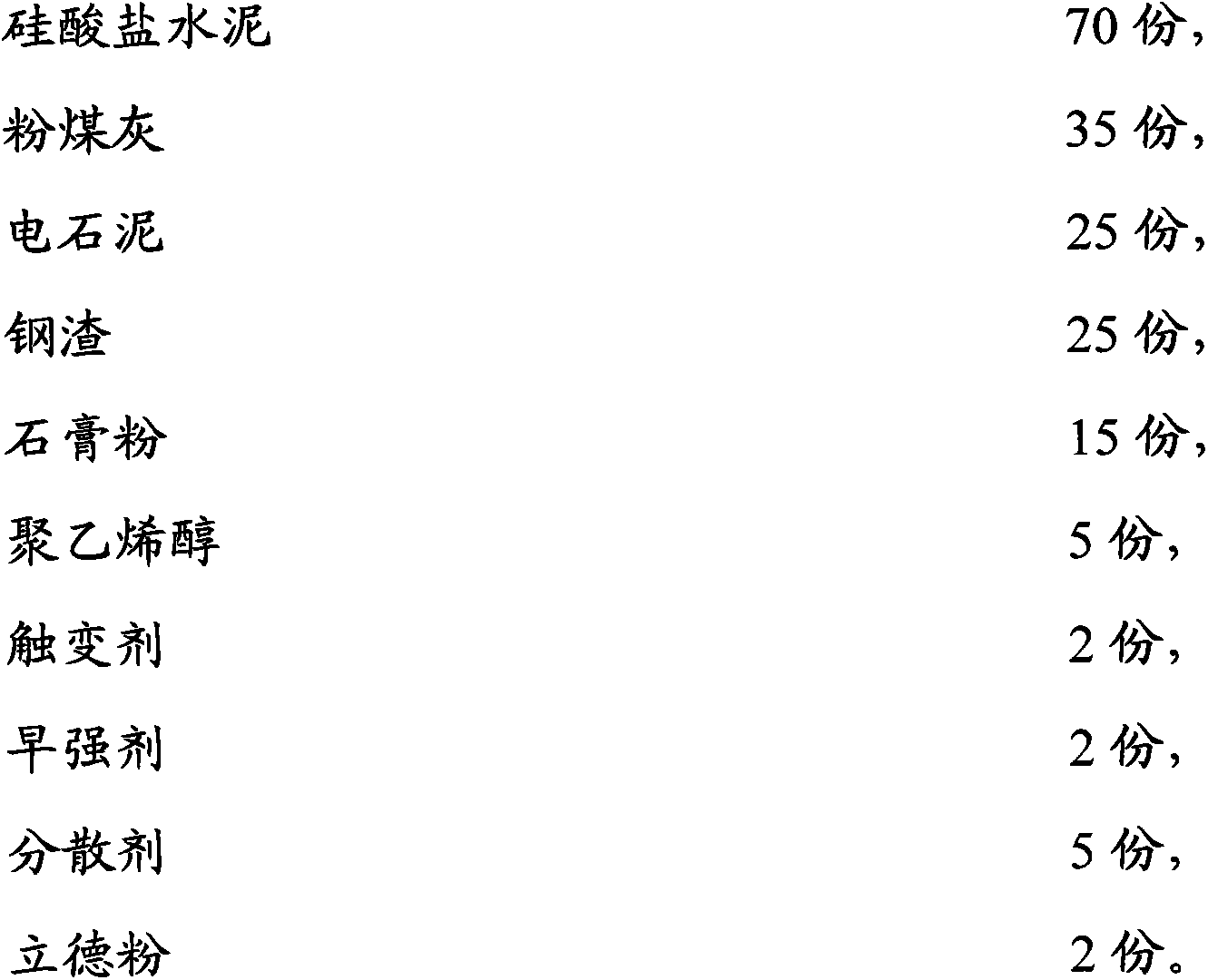

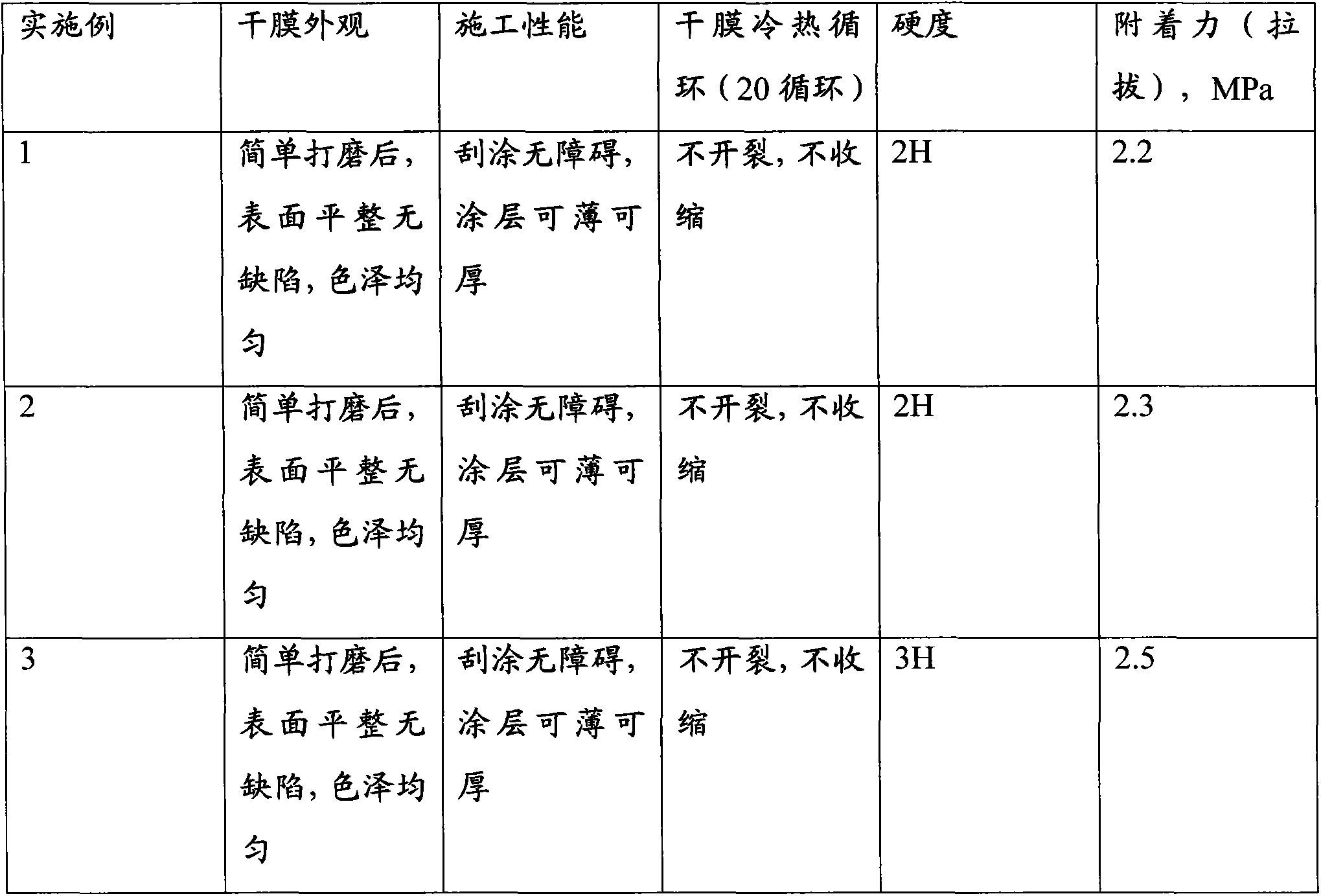

Embodiment 1

[0022] (1) Add 30kg of fly ash, 20kg of calcium carbide mud, and 30kg of steel slag into 100kg of water, stir and mix, and gradually add 5kg of polyvinyl alcohol. After mixing, the slurry is formed and dried in a cool place for 48 hours. The dried clay is placed at 500°C Calcined for 2h, pulverized, and sieved into particles with a particle size of 20 mesh;

[0023] (2) Add the granules obtained in step (1) to 20 kg of hydrochloric acid with a concentration of 0.2 mol / L, add 150 kg of water at a temperature of 60°C and fully stir for 10 minutes, then filter and dry;

[0024] (3) Mix the dried granules in step (2) with 80kg portland cement, 10kg gypsum powder, 5kg thixotropic agent, 2kg early strength agent, 5kg dispersant and 2kg lithopone to obtain architectural decoration Paint 1.

Embodiment 2

[0026] (1) Add 40kg of fly ash, 30kg of calcium carbide mud, and 20kg of steel slag into 120kg of water, stir and mix, and gradually add 10kg of polyvinyl alcohol. After mixing, the slurry is formed and dried in a cool place for 72 hours. The dried clay is placed at 700°C Calcined for 4h, pulverized, and sieved into particles with a particle size of 120 mesh;

[0027] (2) Add the granules obtained in step (1) to 20 kg of hydrochloric acid with a concentration of 0.4 mol / L, add 160 kg of water at a temperature of 60 to 80 ° C and fully stir for 10 to 30 minutes, then filter and dry;

[0028] (3) Mix the dried particles in step (2) with 60kg Portland cement, 20kg gypsum powder, 2kg thixotropic agent, 5kg early strength agent, 2kg dispersant and 5kg lithopone to obtain architectural decoration Paint 2.

Embodiment 3

[0030] (1) Add 35kg of fly ash, 25kg of calcium carbide mud, and 25kg of steel slag into 110kg of water, stir and mix, and gradually add 5kg of polyvinyl alcohol. After mixing, the slurry is formed and dried in a cool place for 62 hours. The dried clay is placed at 600°C Calcined for 3 hours, pulverized, and sieved into particles with a particle size of 100 mesh;

[0031] (2) Add the granules obtained in step (1) to 25 kg of hydrochloric acid with a concentration of 0.3 mol / L, add 155 °C water with a temperature of 70 ° C and fully stir for 15 min, then filter and dry;

[0032] (3) After mixing the dried particles in step (2) with 70g Portland cement, 15kg gypsum powder, 2kg thixotropic agent, 2kg early strength agent, 5kg dispersant and 2kg lithopone, the building decoration paint3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com