Manufacturing method for medium-carbon cold forging steel rods and wires

A manufacturing method, the technology of medium carbon cold heading, applied in the direction of temperature control, metal rolling, etc., can solve the problems of shortening the spheroidizing annealing time, shortening the holding time, and affecting the use of users, so as to improve the heat treatment efficiency, improve the heat treatment efficiency, The effect of shortening the heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

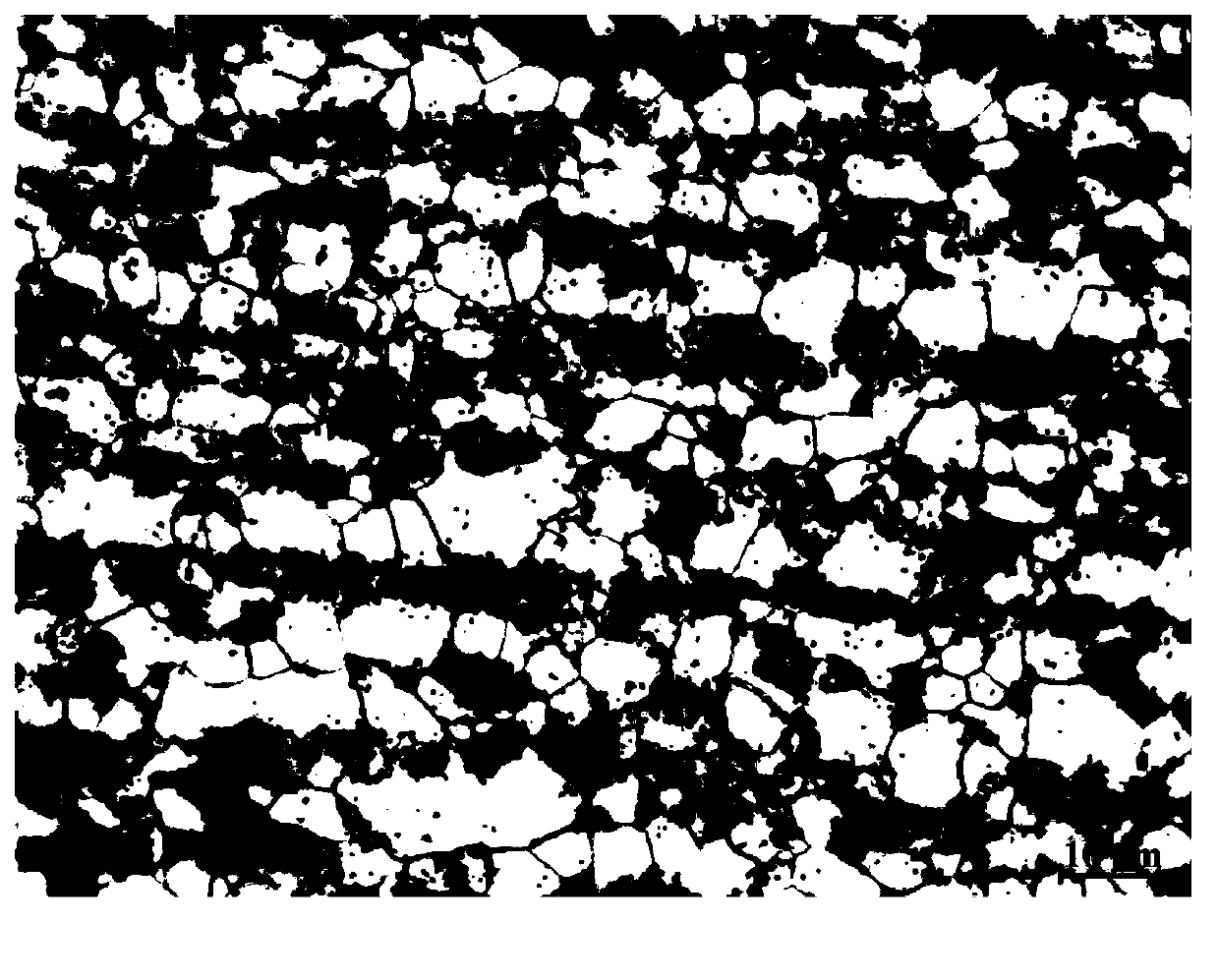

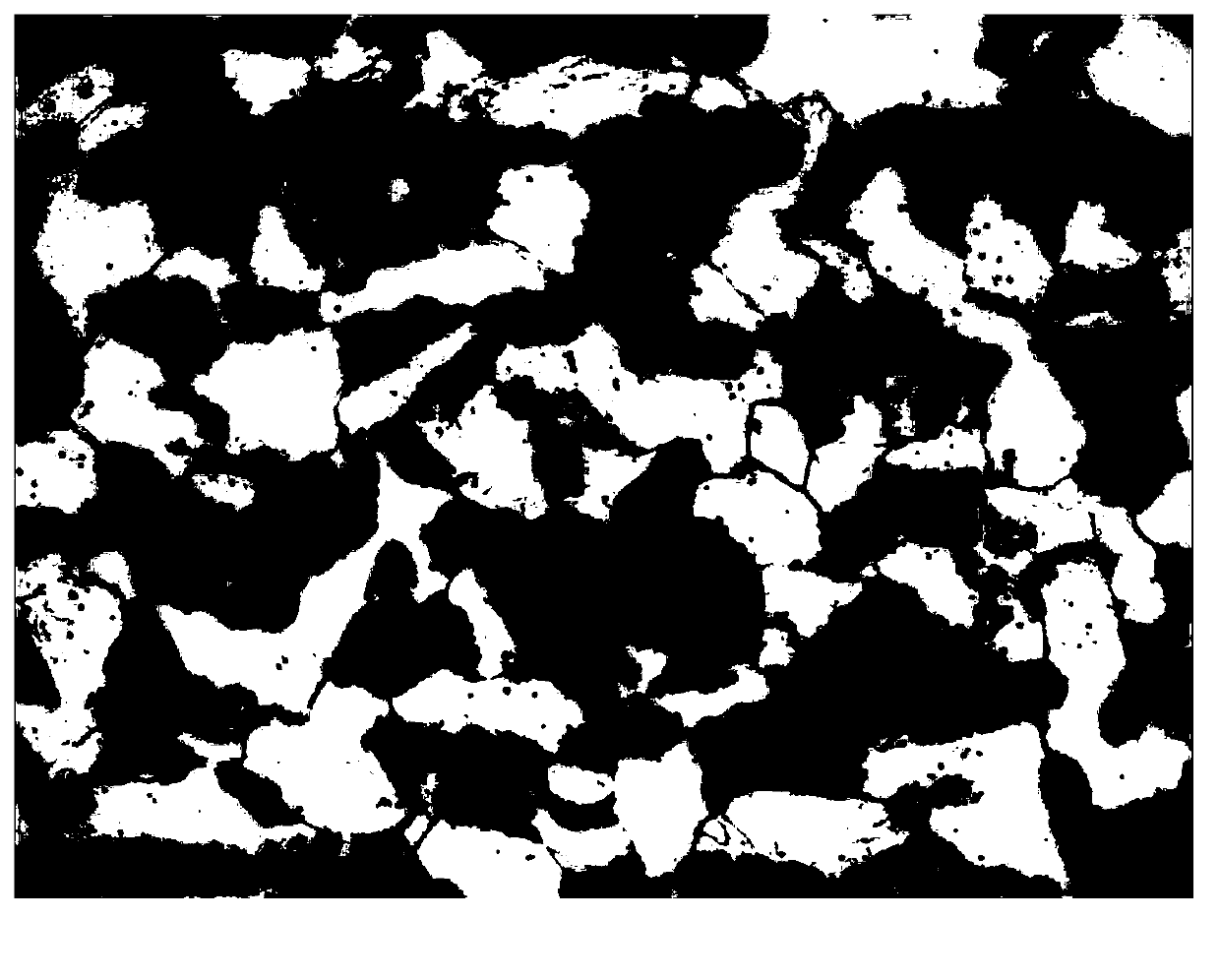

[0053] The billet of medium carbon cold heading steel (SWRCH35K steel grade) is heated at a temperature of 950-1050°C for 1-2 hours, and then rolled into rods and wires in multiple passes on a rod and wire rolling mill. The rolled rods and wires are rapidly cooled by air cooling and air cooled to room temperature. After rapid induction heating pretreatment and spheroidizing annealing heat treatment, the medium carbon cold heading steel of each embodiment is obtained. The specific process parameters of rolling, post-rolling air cooling, rapid induction heating pretreatment and spheroidizing annealing heat treatment are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com