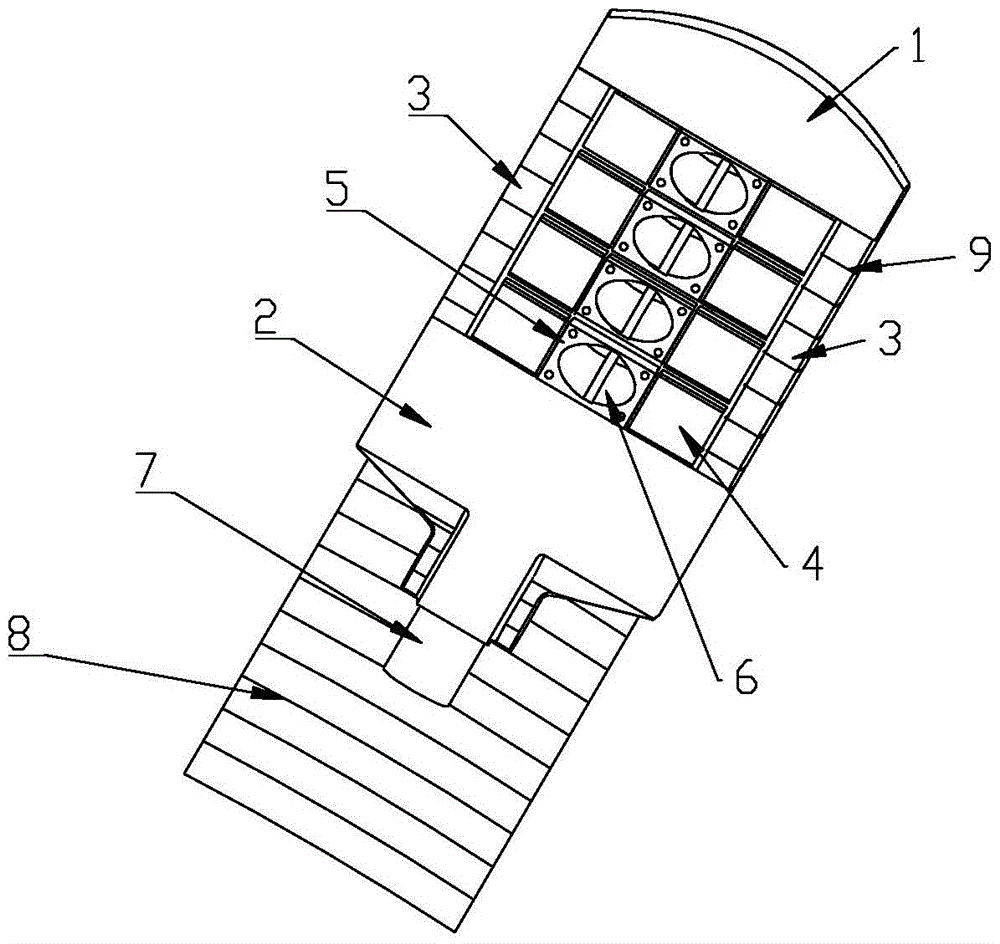

High heat dissipation combined led street light

A LED street lamp, high heat dissipation technology, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problem of easy heating of LED modules, and achieve good coating process and service life Long, good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of above-mentioned heat dissipation coating of the present invention is:

[0028] (1) Weigh each component of the formula ratio, then first add the carbon nanotubes into ethylene glycol at a temperature of 50-80°C, and stir evenly;

[0029] (2) Then the inorganic colloidal particles are added to the mixed system of epoxy resin and methyl methacrylate and stirred evenly;

[0030] Mix the solution of step (1) and step (2), then add spinel after electronic transition, rare earth element oxide and stabilizer and stir evenly to obtain the heat dissipation coating, and mechanically spray the above coating on the The upper and lower surfaces of the aluminum plate are provided with a heat dissipation coating.

Embodiment 1

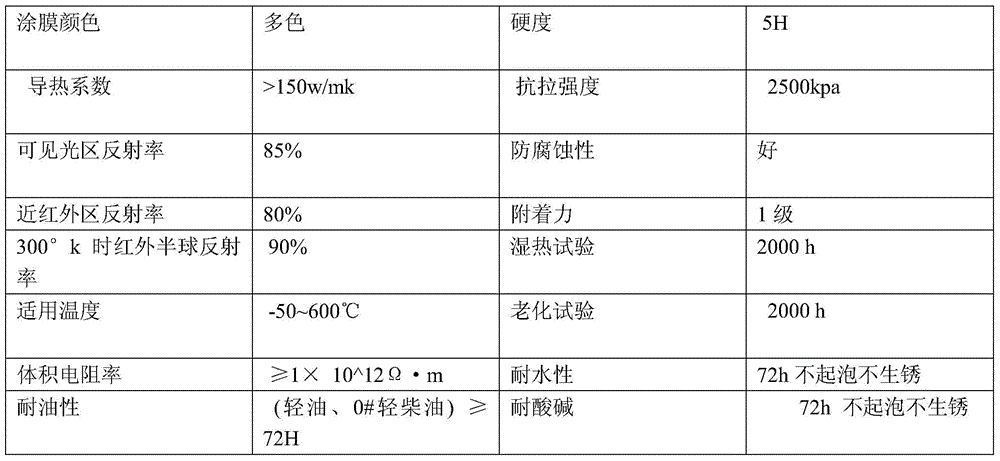

[0031] Embodiment 1: 15 parts of inorganic colloid particles, 2.5 parts of carbon nanotubes, spinel (LiMn 2 o 4 Spinel) 40 parts, 0.05 parts of cerium oxide, 0.3 parts of kerosene, 3 parts of epoxy resin, 10 parts of methyl methacrylate, 3 parts of ethylene glycol. The above-mentioned heat dissipation coating was applied to the upper and lower surfaces of the aluminum plate with a mechanical spray gun to obtain a heat sink, and the data obtained by testing the heat sink are shown in Table 1:

[0032] Table 1. Heat sink performance testing parameter list

[0033]

[0034] The heat sink 9 is glued in the gap and sealed by the sealant. This structure is used to seal the cavity to prevent water from entering the cavity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com